Mild Steel Pipe Joining Solutions

Mild steel (ms) flange adaptors for connecting plain-end pipes to flanged equipment.

Mild Steel Pipe Joining Solutions

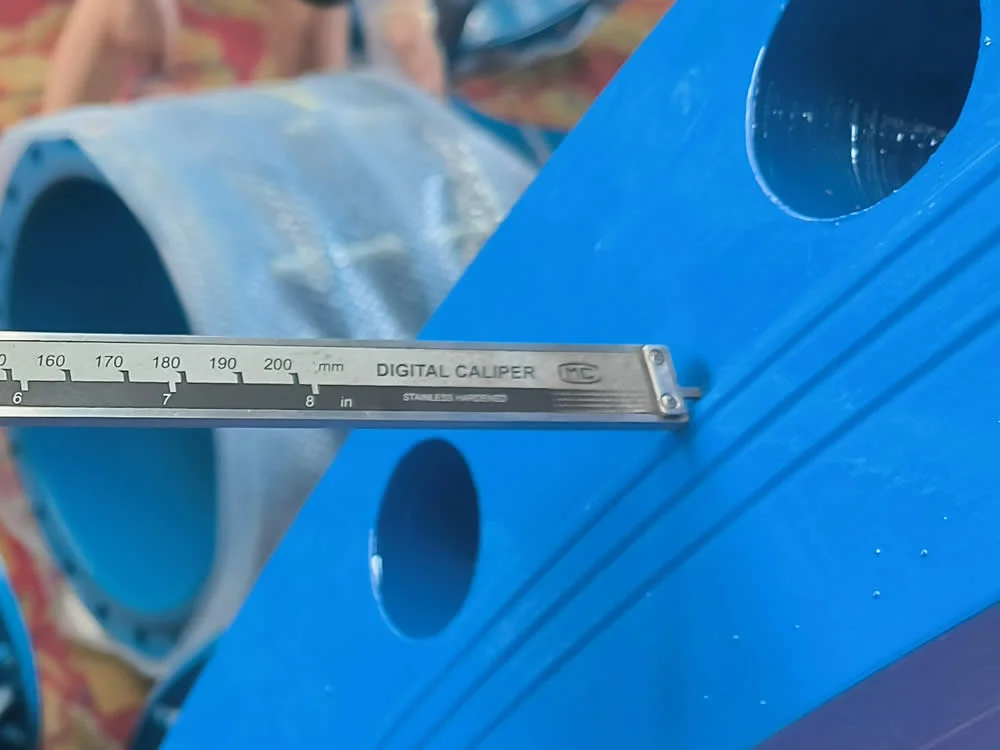

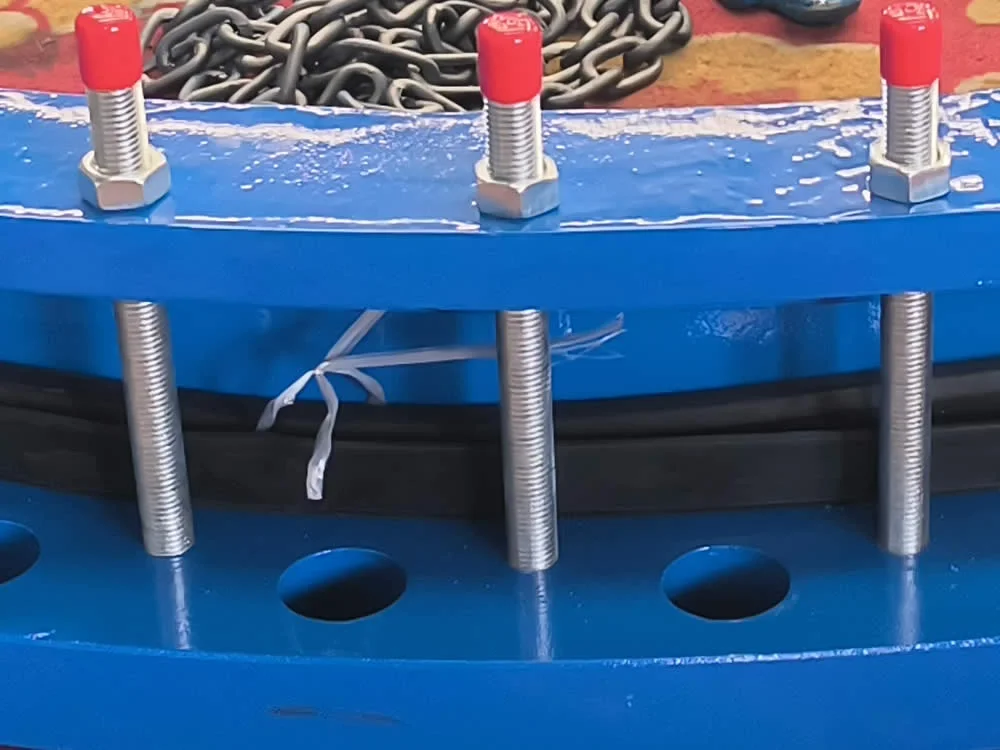

Mild steel (ms) flange adaptors for connecting plain-end pipes to flanged equipment. cost-effective, painted for corrosion protection. sizes dn50-dn2000, pn10/16. ideal for water supply, irrigation, and low-pressure systems.

MS (Mild Steel) flange adaptors are mechanical fittings made from carbon steel (Q235/A3) with a fixed flange on one end and a socket/spigot on the other. They enable quick, weld-free connection of plain-end pipes to flanged components, ideal for water, irrigation, and low-pressure industrial systems.

Coated with fusion-bonded epoxy (blue/black) for corrosion protection; compatible with steel, DI, PVC, and PE pipes (with inserts for PE).

| Parameter | Specification |

|---|---|

| Material | Mild Steel (Q235B/A3); Epoxy Coated |

| Size Range | DN50–DN2000 (2"–80") |

| Pressure Rating | PN10 / PN16 (Class 150 optional) |

| Flange Standard | EN1092-2 PN10/16, BS4504, ANSI B16.5 Class 150 |

| Gasket | EPDM (WRAS/NSF approved) |

| Bolts/Nuts | Galvanized or Stainless Steel |

| Coating | Fusion Bonded Epoxy (250-400 μm) |

| Temperature | -10°C to +80°C (EPDM) |

Custom designs and larger diameters available on request.

At Sunny Steel, we are guided by three fundamental core values that shape our approach and drive our success.

Flange adapters allow for the connection of different types of flanges, such as ANSI, DIN, or JIS flanges, enabling compatibility between different flange standards. This versatility makes it easier to connect and integrate various components and piping systems.

Flange adapters provide flexibility in adapting flanged components to non-flanged equipment or systems. They allow for the connection of flanged pipes to valves, pumps, or other equipment that may not have flanged ends, eliminating the need for extensive modifications or welding.

Flange adapters simplify the installation and removal process compared to welding or other permanent joining methods. They can be easily aligned and bolted together, reducing downtime during maintenance or repairs.

The use of gaskets or sealing elements with flange adapters ensures a tight and leak-proof connection between flanged components. This helps prevent fluid or gas leakage, promoting safety and efficiency in the piping system.

Flange adapters can be a cost-effective solution compared to welding or using custom-made flanged components. They eliminate the need for complex fabrication, reduce labor costs, and enable faster installation and disassembly.

Flange adapters are typically made from sturdy and corrosion-resistant materials, ensuring long-lasting performance and reliability in demanding environments. They can withstand high pressures, temperature variations, and chemical exposures.

Flange adapters allow for modular construction and easy reconfiguration of piping systems. They can be easily disconnected and reused, offering flexibility in system design, modification, or expansion.

SUNNYSTEEL

The use of MS flange adapters helps in simplifying the installation and removal of the following

Pump stations, sewage treatment plants, water treatment plants and other more applications use flange adaptors.

Large diameter carbon steel painted flange adapte

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0