- Abrasion-resistant Hub Shields For Vsi Crushers

Discover high-performance hub protection shields for vertical shaft impact (vsi) crushers.

Superior wear resistant hub liner and rotor hub protection using basalt lined or ceramic lined technology for vertical shaft impact crushers and sand making machines

Our Hub Protection series delivers robust rotor hub protection for the central hub in Vertical Shaft Impact (VSI) crushers, sand making machines, and vertical shaft impactors. Engineered from high-strength steel with premium basalt lined, ceramic lined, or abrasion resistant composite interiors, these heavy-duty annular hub protectors and rotor hub shields withstand extreme impact, high-velocity abrasion, erosion, and corrosive conditions in mining, quarrying, aggregate processing, and crushing applications.

The donut-shaped annular design includes a thick outer steel shell for structural strength, reinforced edges, and an inner wear-resistant lining (cast basalt, alumina ceramic, or ceramic composite) offering exceptional hardness (8-9 Mohs) and smooth surface finish to minimize material adhesion, buildup, and extend service life 5-10 times longer than unprotected rotor hubs or standard hub liners.

Fused cast basalt lined or high-alumina ceramic lined for maximum wear resistant hub liner protection against sand, gravel, ore, and abrasive impacts in VSI crushers.

Advanced rotor hub protection preventing damage from moisture, chemicals, high-temperature operations, and centrifugal forces in vertical shaft impact crushers.

Large-diameter ring structure precision-machined for perfect fit on VSI crusher rotors, including mounting holes for easy installation of hub protectors and shields.

Welded high-strength steel body with reinforced alloy rims for durable rotor hub shield performance and reliable abrasion resistant protection.

Withstands up to 350-500°C with basalt lined or ceramic lined materials, ideal for high-heat VSI crusher hub protection applications.

Wear resistant hub liners and rotor hub protectors reduce replacements, minimize downtime, and lower repair costs in quarries, power plants, cement mills, and mining operations.

Serving 100+ countries with localized support and fast delivery.

ISO 9001, API, and ASTM compliant – full traceability and third-party inspection.

Cost-effective solutions that extend equipment life and reduce downtime.

Hub Protection, are manufactured using different material compositions depending on the application, operating conditions, and performance requirements:

Often ceramic block inlaid roller sleeves, consisting of three layers: ductile iron (base), high-chromium cast iron (intermediate), and wear-resistant ceramic blocks (outer layer). This design balances high hardness with excellent toughness.

Includes Ni-hard cast iron and high-chromium cast iron, achieving hardness above 58 HRC. Offers strong wear resistance but lower toughness, with potential for cracking under heavy impact.

Such as ZG30Mn cast steel, optimized for improved hardness and wear resistance. Many undergo arc gouging finishing and non-destructive testing (ultrasonic, magnetic particle, dye penetrant) to ensure quality and extend service life.

Outer layer uses alloy cast iron for high hardness and wear resistance, while the inner layer is gray cast iron for toughness and vibration absorption. The roller shaft is typically made of high-quality 45# carbon structural steel, assembled with interference fit for a strong, integrated structure.

Both vertical roller mills and roller presses operate based on the principle of material bed milling, ensuring efficient grinding through particle-to-particle interaction rather than direct metal contact.

During the grinding process, only a small portion of material particles directly contact the grinding components. Under applied pressure, the particles form a stable material bed. Through stress transmission and interaction between particles, the material is cracked, broken, and finely ground, resulting in high efficiency and reduced component wear.

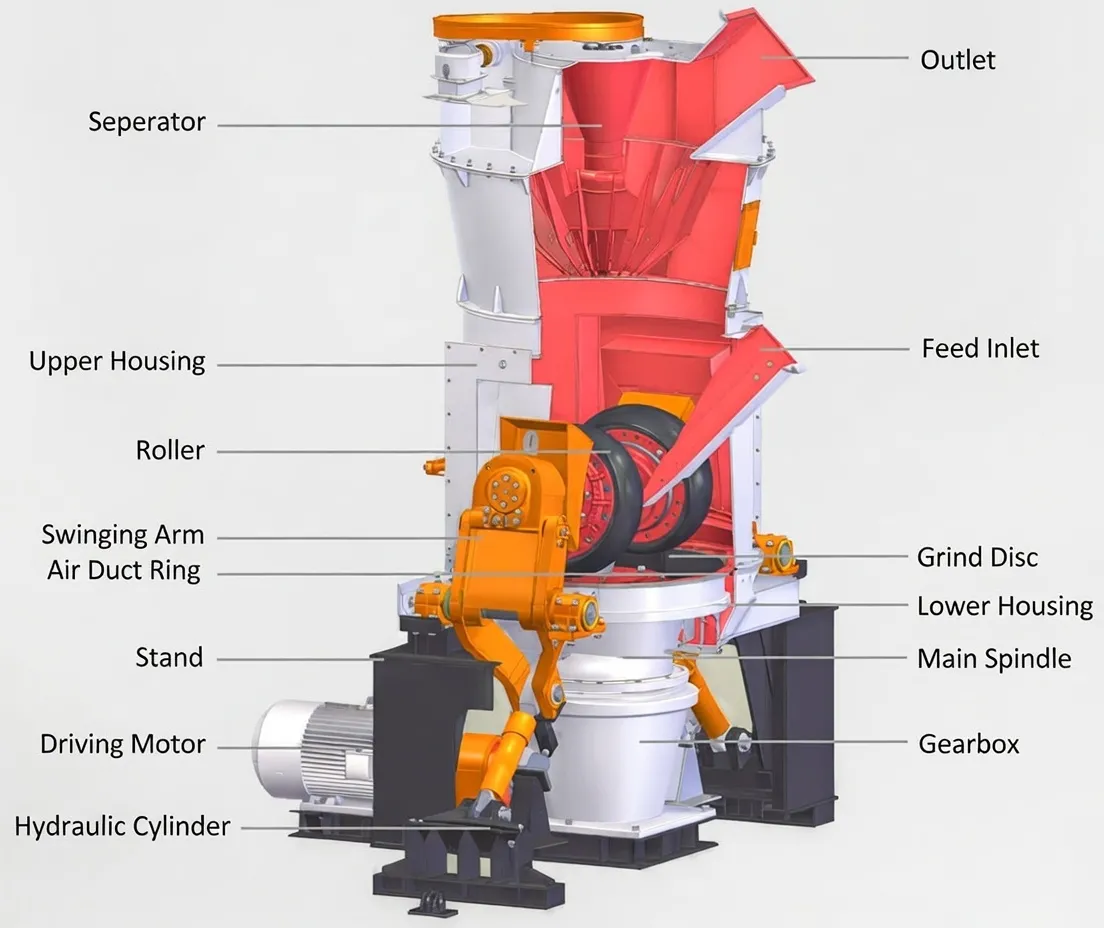

In a vertical roller mill, the grinding components consist of rollers and a grinding disc. The grinding pressure is mainly generated by the rollers and is typically applied through a hydraulic loading system.

Material is fed onto the grinding disc from the center or side of the upper housing. As the disc rotates, a uniform material layer is formed. When the material passes between the rollers and the grinding disc, it is ground under combined extrusion and shear forces.

A roller press uses two rollers of equal size as the grinding components. Material falls vertically from the top and forms a compact material bed between the rollers. Under the high extrusion force applied by the rollers, the material is compressed and ground into fine particles.

Roller presses are available in two drive configurations: double drive and single drive. The double drive roller press, where both rollers are independently driven, is the most commonly used design. In a single drive configuration, one roller is motor-driven, while the second roller is driven via a gear transmission.

Hub Protection

There are fundamental differences between the design structures of vertical roller mills and roller presses, which directly influence grinding efficiency, energy utilization, and product fineness.

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0