Fast Speed & High Pressure

Explore our durable conical grinding roller for vertical roller mill, featuring tapered design for fast running speed and high grinding pressure.

Fast Speed & High Pressure

Explore our durable conical grinding roller for vertical roller mill, featuring tapered design for fast running speed and high grinding pressure.

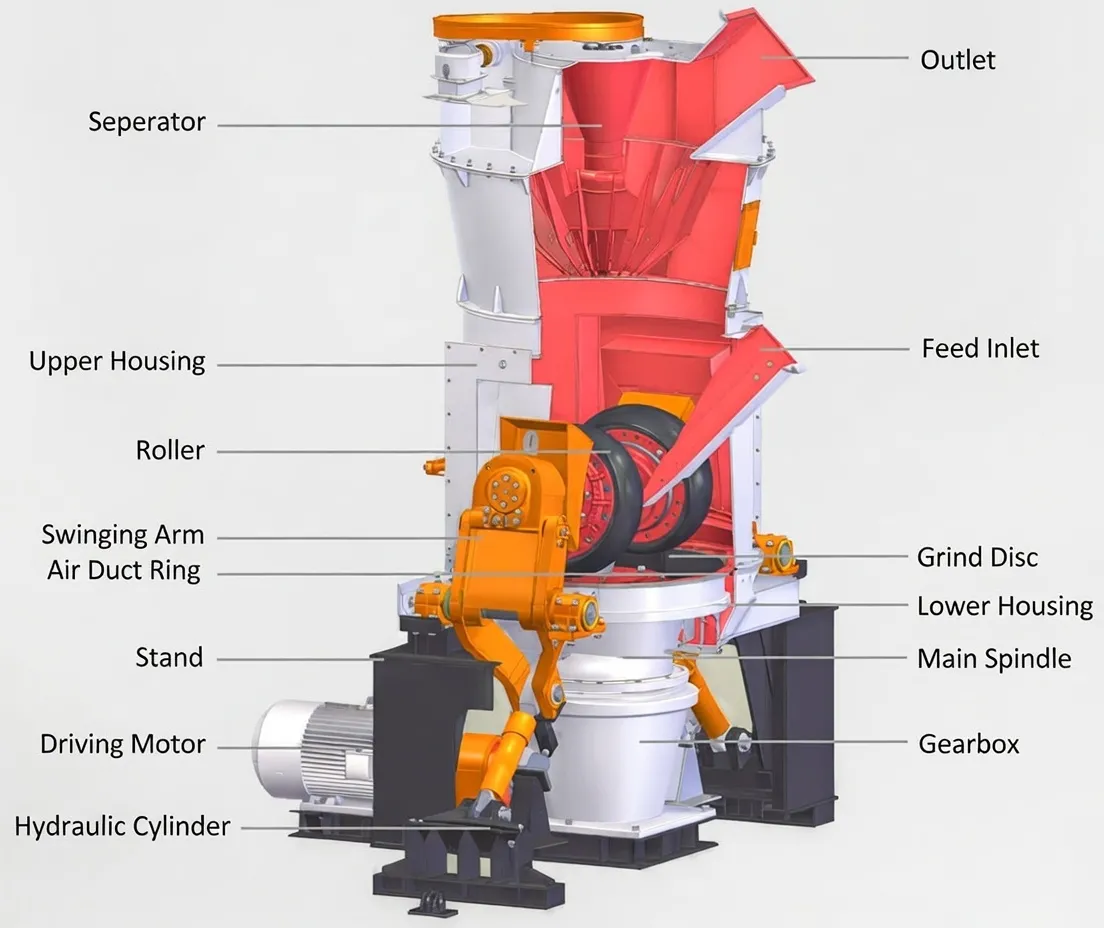

The Conical Grinding Roller is a specialized wear part in vertical roller mills (VRM), designed with a tapered (conical) shape that works in tandem with a flat grinding table. This configuration excels in high-pressure, high-speed grinding of cement raw materials, clinker, coal powder, and slag, offering advantages in efficiency, compactness, and ease of upkeep compared to other roller forms.

Engineered for superior performance, our tapered VRM grinding roller provides distinct advantages over wheel-type or cylindrical designs:

These characteristics make the conical design particularly suitable for high-output cement operations seeking optimized energy consumption and reliability.

| Parameter | Details |

|---|---|

| Design Type | Conical / Tapered (pairs with flat grinding table) |

| Material Options | High Chromium Cast Iron, Alloy Steel (e.g., 42CrMo base), Hardfaced Layers |

| Hardness (Hardfacing) | HRC 56-65 |

| Wear Layer Thickness | 15-20 mm typical (hardfaced variants) |

| Key Advantages | High pressure, fast speed, lightweight, easy maintenance |

| Compatibility | Customized for major VRM brands (e.g., Loesche, similar conical designs) |

| Condition | Brand New / OEM Quality |

Serving 100+ countries with localized support and fast delivery.

ISO 9001, API, and ASTM compliant – full traceability and third-party inspection.

Cost-effective solutions that extend equipment life and reduce downtime.

Conical Roller, are manufactured using different material compositions depending on the application, operating conditions, and performance requirements:

Often ceramic block inlaid roller sleeves, consisting of three layers: ductile iron (base), high-chromium cast iron (intermediate), and wear-resistant ceramic blocks (outer layer). This design balances high hardness with excellent toughness.

Includes Ni-hard cast iron and high-chromium cast iron, achieving hardness above 58 HRC. Offers strong wear resistance but lower toughness, with potential for cracking under heavy impact.

Such as ZG30Mn cast steel, optimized for improved hardness and wear resistance. Many undergo arc gouging finishing and non-destructive testing (ultrasonic, magnetic particle, dye penetrant) to ensure quality and extend service life.

Outer layer uses alloy cast iron for high hardness and wear resistance, while the inner layer is gray cast iron for toughness and vibration absorption. The roller shaft is typically made of high-quality 45# carbon structural steel, assembled with interference fit for a strong, integrated structure.

Both vertical roller mills and roller presses operate based on the principle of material bed milling, ensuring efficient grinding through particle-to-particle interaction rather than direct metal contact.

During the grinding process, only a small portion of material particles directly contact the grinding components. Under applied pressure, the particles form a stable material bed. Through stress transmission and interaction between particles, the material is cracked, broken, and finely ground, resulting in high efficiency and reduced component wear.

In a vertical roller mill, the grinding components consist of rollers and a grinding disc. The grinding pressure is mainly generated by the rollers and is typically applied through a hydraulic loading system.

Material is fed onto the grinding disc from the center or side of the upper housing. As the disc rotates, a uniform material layer is formed. When the material passes between the rollers and the grinding disc, it is ground under combined extrusion and shear forces.

A roller press uses two rollers of equal size as the grinding components. Material falls vertically from the top and forms a compact material bed between the rollers. Under the high extrusion force applied by the rollers, the material is compressed and ground into fine particles.

Roller presses are available in two drive configurations: double drive and single drive. The double drive roller press, where both rollers are independently driven, is the most commonly used design. In a single drive configuration, one roller is motor-driven, while the second roller is driven via a gear transmission.

Conical Roller

There are fundamental differences between the design structures of vertical roller mills and roller presses, which directly influence grinding efficiency, energy utilization, and product fineness.

Vertical Roller Mill Grinding Roller

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0