SS 309 Shield

Stainless 309s tube shields are made of 309s stainless steel and can be customized to fit perfectly straight sections

Learn about 309S stainless steel pipe fittings and ferrules, their use in superheater tubes erosion shields, and their high-temperature and corrosion resistance properties for boiler applications.

Download PDFType 309S stainless steel is a low carbon version of Type 309. Because of its lower carbon-content, Type 309S minimizes carbide precipitation, and improves weldability.

Continental Steel has supplied many customers with Type 309S stainless steel over our 20 year history. Type 309S is available in a number of different sizes and forms including sheet, sheet coil, plate, round bar, flat bar, and tube. As with all of the products we supply, Type 309S meets the leading standards like ASTM, AMS, AISI, UNS, and DIN.

309S stainless steel pipe fittings and ferrules are engineered for use in high-temperature environments, particularly as erosion shields for superheater tubes in boilers and heat exchangers. These components provide superior protection against wear, corrosion, and thermal stress.

309S stainless steel is a low-carbon variant of 309, renowned for its excellent high-temperature oxidation resistance and improved weldability. Its properties make it ideal for extreme environments.

High-temperature resistance up to 1000°C–1100°C; excellent corrosion resistance in aggressive and oxidative environments; and reduced carbide precipitation, enhancing weldability and intergranular corrosion resistance.

Available in standard material thicknesses of 2mm, 3mm, or custom specifications. Shapes include straight, curved (inner and outer), and specialized designs for finned or S-bend tubes. Sizes are compatible with tube diameters like 38.1mm, 50.8mm, and 57.15mm.

These components extend the service life of equipment, minimize maintenance costs, and ensure reliable operation in high-stress environments. They are crafted from certified materials, including chromium carbide coatings for enhanced wear resistance.

309S stainless steel is widely used in superheater tubes erosion shields to protect against erosion and wear. It is also ideal for high-pressure, high-temperature pipe fittings and ferrules in industrial boilers and heat exchangers.

Contact us today for customized designs, detailed product specifications, or pricing tailored to your industrial requirements!

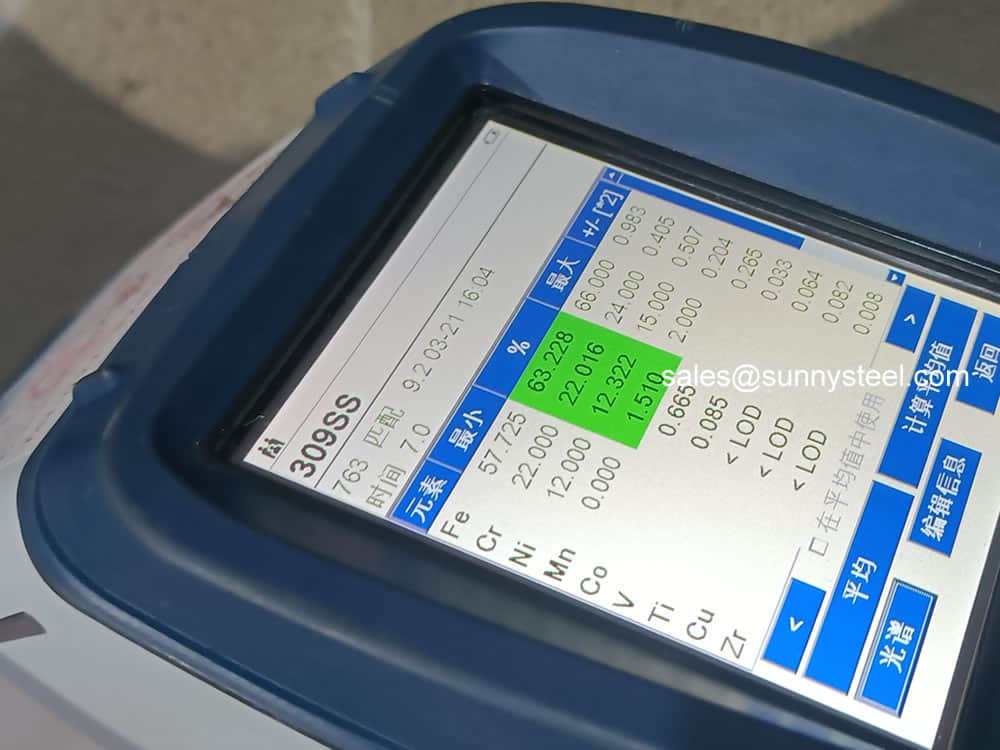

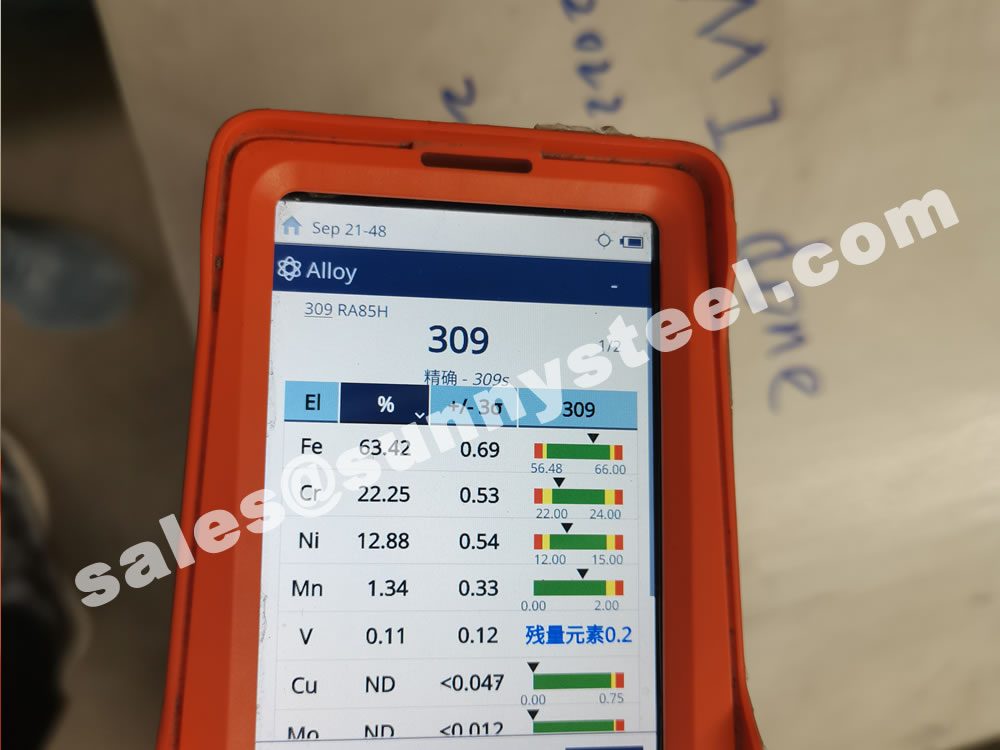

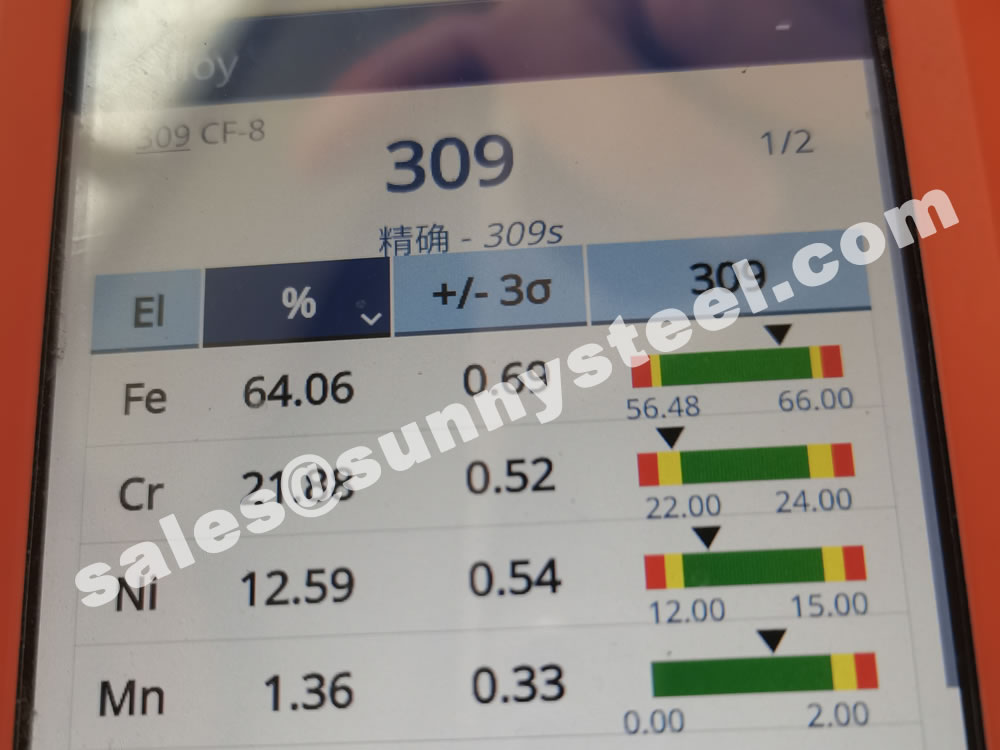

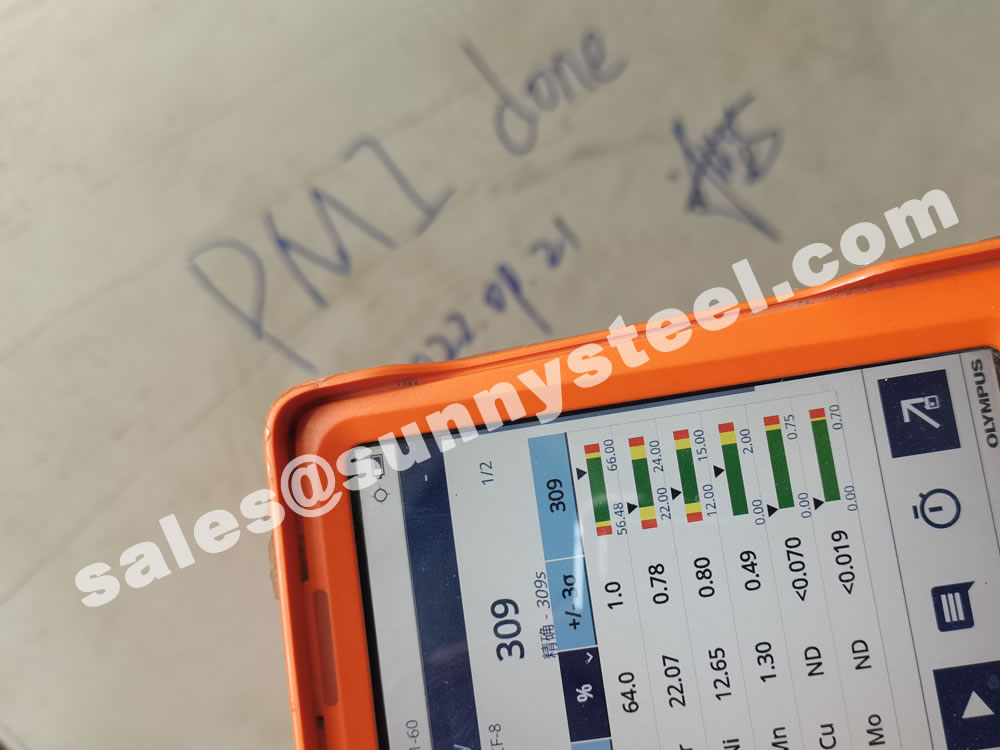

The following table shows the chemical composition of grade 309 stainless steel.

| Grade | C | Mn | Si | P | S | Cr | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| SS 309 | 0.20 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 22.0 – 24.0 | 12.0 – 15.0 | Balance |

| SS 309S | 0.08 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 22.0 – 24.0 | 12.0 -15.0 | Balance |

The physical properties of grade 309 stainless steel are given in the following table.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8 g/cm3 | 0.289lb/in3 |

| Melting point | 1455°C | 2650°F |

The following table outlines the mechanical properties of annealed grade 309 stainless steel.

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 620 MPa | 89900 psi |

| Yield strength (@ strain 0.200%) | 310 MPa | 45000 psi |

| Izod impact | 120 - 165 J | 88.5 - 122 ft-lb |

| Shear modulus (typical for steel) | 77 GPa | 11200 ksi |

| Elastic modulus | 200 GPa | 29008 ksi |

| Poisson's ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break (in 50 mm) | 45% | 45% |

| Hardness, Brinell | 147 | 147 |

| Hardness, Rockwell B | 85 | 85 |

| Hardness, Vickers (converted from Rockwell B hardness) | 169 | 169 |

The thermal properties of grade 309 stainless steel are displayed in the following table.

| Properties | Metric | Imperial |

|---|---|---|

| Thermal expansion co-efficient (@ 0-100°C/32-212°F) | 14.9 μm/m°C | 8.28 μin/in°F |

| Thermal conductivity (@ 0-100°C/32-212°F) | 15.6 W/mK | 108 BTU in/hr.ft².°F |

Other designations equivalent to grade 309 stainless steel are included in the following table.

| Standard 1 | Standard 2 | Standard 3 | Standard 4 |

|---|---|---|---|

| ASTM A167 | ASME SA249 | ASTM A314 | ASTM A580 |

| ASTM A249 | ASME SA312 | ASTM A358 | FED QQ-S-763 |

| ASTM A276 | ASME SA358 | ASTM A403 | FED QQ-S-766 |

| ASTM A473 | ASME SA403 | ASTM A409 | MIL-S-862 |

| ASTM A479 | ASME SA409 | ASTM A511 | SAE J405 (30309) |

| DIN 1.4828 | ASTM A312 | ASTM A554 | SAE 30309 |

The presence of nickel gives 304 stainless steel its corrosion resistance and makes it suitable for various general-purpose applications. 2. 309 Stainless Steel: Compared to 304, 309 stainless steel contains a higher percentage of chromium and nickel, typically around 23% chromium and 12% nickel.

Type 309 is employed for parts requiring both corrosion and heat resistance and oxidation resistance up to 2000 °F. Strength at elevated temperatures is similar to that of 18-8 Stainless Steels. This alloy posses excellent resistance to oxidation as well as high tensile and creep strengths at elevated temperatures.

Type 309S Stainless Steel is identical to Type 309 except for a lower carbon content that minimizes carbide precipitation and improves weldability.

Use 309L (including ER309LSi) when joining mild steel or low alloy steel to stainless steels, for joining dissimilar stainless steels such as 409 to itself or to 304L stainless, as well as for joining 309 base metal.

316 contains a minimum 2.0% molybdenum which makes it much more corrosion resistant than 304 however, as it is a more expensive element, generally makes 316 a more expensive grade of metal.

309 has a machinability rating of 43% relative to AISI B1112 steel. Room temperature forming is suggested. Weld with AWS E309-16 covered electrodes or ER309 bare wire. Some Rod Coil is stocked as 309E which is EN 1.4828.

| 309 | 309S | 309H |

|---|---|---|

| UNS S30900 | UNS S30908 | UNS S30909 |

| ASTM A240 | ASTM A240 | ASTM A240 |

| ASTM A480 | ASTM A480 | ASTM A480 |

| ASME SA240 | ASME SA240 | ASME SA240 |

| AMS 5523 | AMS 5523 | AMS 5523 |

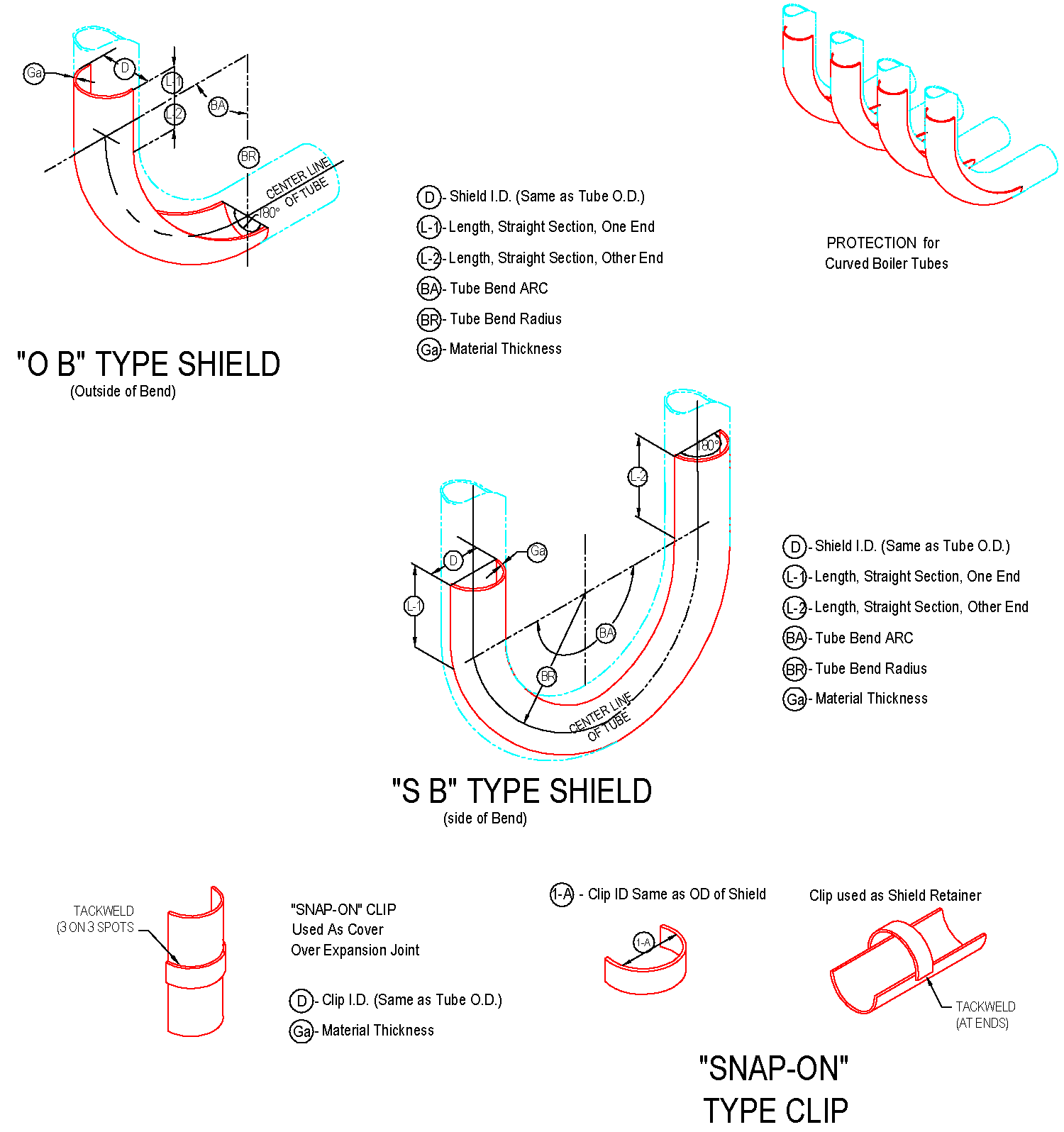

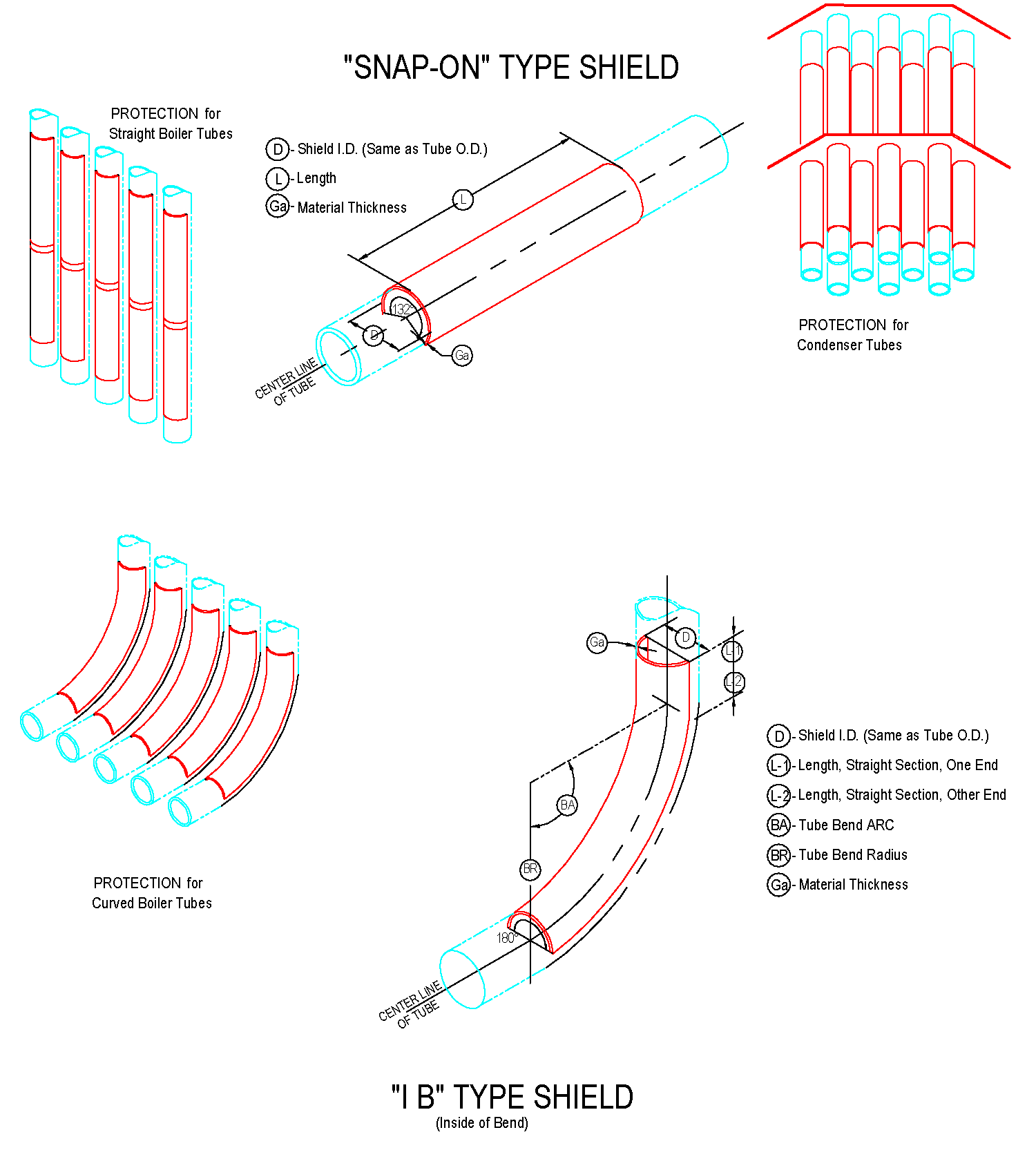

The cross-sectional shape of boiler tubes shields is mostly semi-circular (180 degrees), and there are also 120-160 degrees.

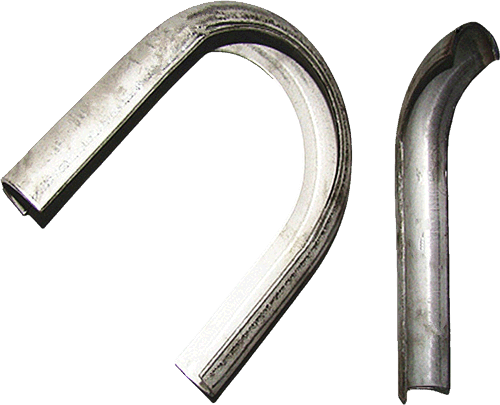

It is mainly used on finned tubes (water-cooled walls); boiler tube erosion shields are divided into direct wear-resistant shields, in-curve, anti-wear shields, outer-curve, anti-wear shields, side-curve anti-wear shields, s-curve anti-wear shields, etc.

The length of the straight anti-wear shields ranges from 20mm to 3000mm, and the general length of 1000-2000mm is commonly used. The anti-wear shields with bends generally requires a processing drawing and the following parameters should be on the drawing: outer diameter of the pipe used, bending of the pipe Radius R (to the center of the pipe), the degree of bending angle, and the length of the straight sections on both sides of the arc segment of the wear-resistant shields.

The most basic parameter of boiler tubes shields is the outer diameter of the tube used (that is, the inner diameter of boiler tubes erosion shields). The main specifications of the tube are: 32, 38, 42, 44.5, 48, 51, 57, 60, 63.5 , 76, 89mm, etc . the inner diameter of the boiler tubes erosion shields is usually 1-3mm larger than the outer diameter of the tube used, depending on the actual requirements.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.