Erosion Shields

Erosion Shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

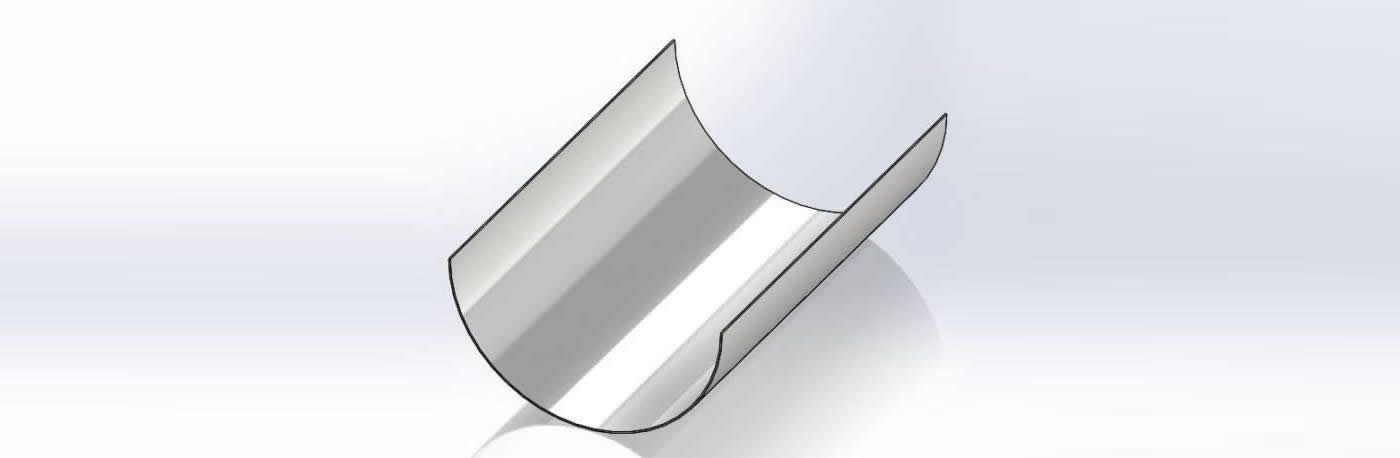

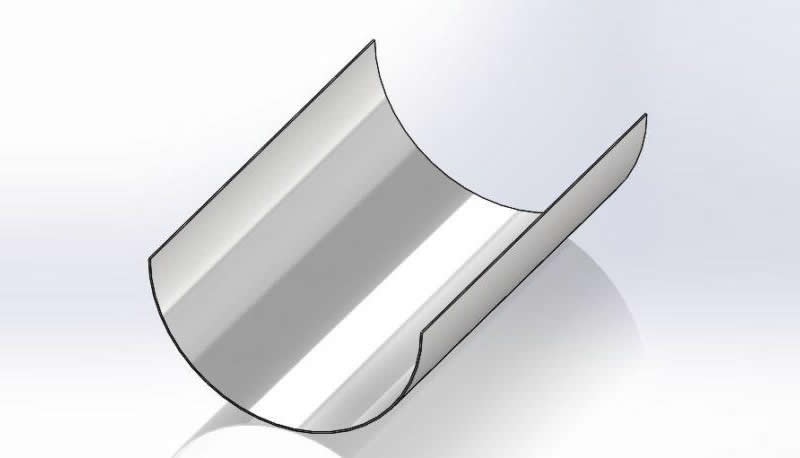

Custom curved tube shields are specially designed components used to protect tubes in boilers, heat exchangers, and other high-temperature applications.

Download PDF

Custom Curved Tube Shields are protective components used in boilers and heat exchangers to prevent wear and erosion of tubes in areas subjected to high-velocity steam or corrosive environments. These shields are designed to match the curvature of the tubes, providing a close fit and maximum protection. They are typically made from high-grade stainless steel or alloy materials, ensuring durability and resistance to heat and corrosion. Customization allows these shields to be tailored to specific applications, enhancing the longevity and efficiency of the equipment.

Curved tube shields can be manufactured to cover both outside and inside curves of tubing. Complete coverage is available with overlapping shields.

All these years have enhanced our capabilities and enabled us to produce all kinds of standard tube shield as well as custom snap rings as per customer’s specifications. We have numerous combinations of sizes readily available in large number of stocks and can fabricate custom sizes according to customer’s requirement.

Different types of stainless steel are selected according to the specific conditions of different working conditions.

The boiler was originally designed to be accurate. Different materials have different temperature resistance and mechanical strength, generally has a temperature resistance of 600 ℃ or less.

We can also supply boiler tubes erosion shields of other materials.

Tube shields are custom made to fit perfectly to straight sections, curved sections and even finned and specialised tubing.

Boiler tube erosion shields, also known as anti-corrosion shields, anti-wear plate, anti-wear protection shields, anti-wear cover plate, anti-corrosion cover plate, boiler climbing pipe, anti-wear pressure plate, etc. , which are used in combination with snap rings.

Boiler tube erosion shields are produced using a high-pressure press and professional mould pressing. The production time is short, the welding performance is good, the welding should not fall off, the surface is smooth, and the appearance is beautiful. Boiler tube erosion shields with bends are formed by pressing on a press or bending with a special abrasive on a tube bender.

Boiler tube shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.