- Erosion Shield For Pipelines

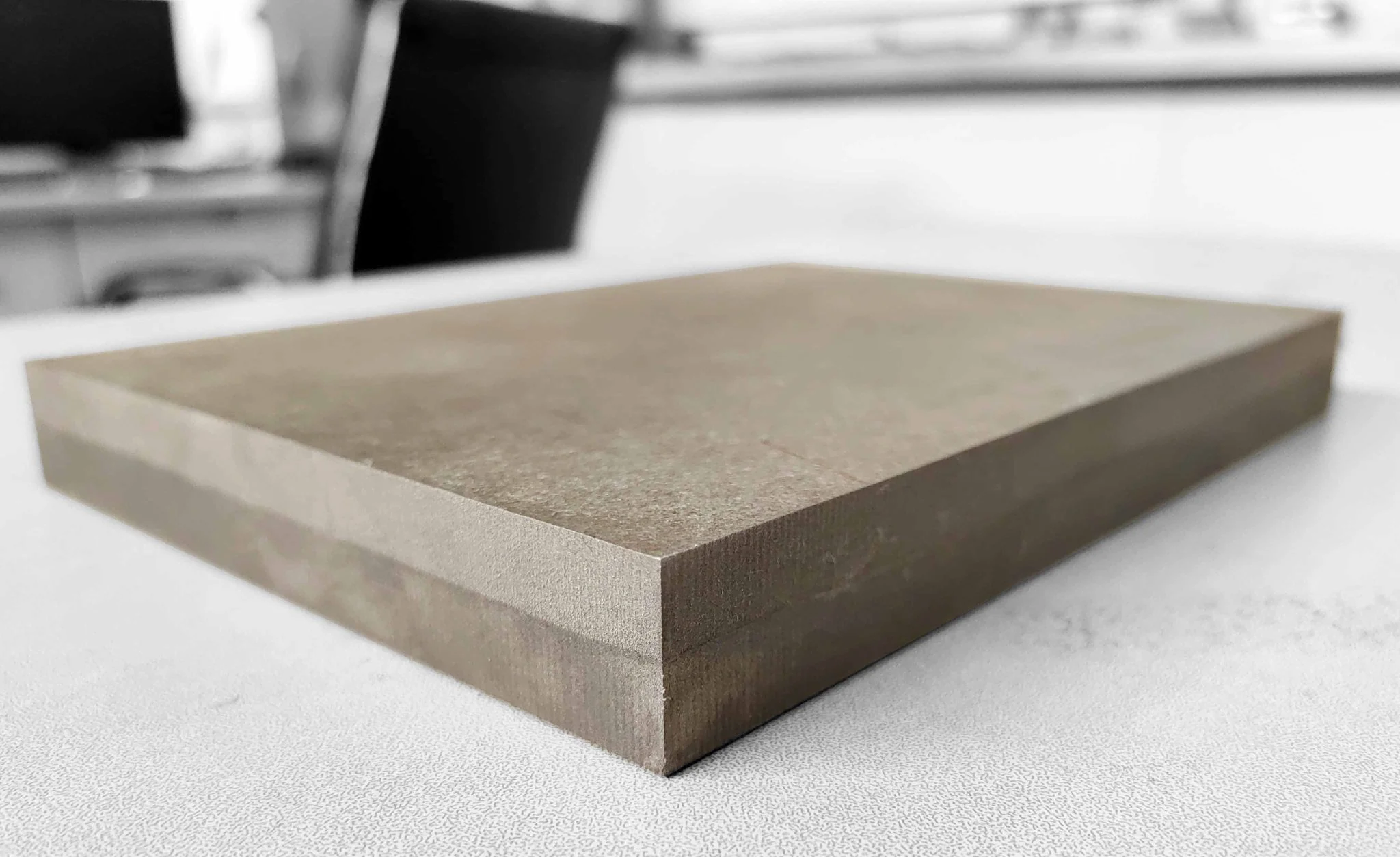

Defend your boiler pipes and industrial pipelines with chromium carbide overlay wear plate, offering hrc58-62 hardness and up to 1100°f resistance to combat erosion, corrosion, and abrasion. this cost-effective cladding solution extends equipment life 5-10x, minimizes downtime in mining and power sectors, and ensures seamless integration for reliable, low-maintenance protection against harsh environments.

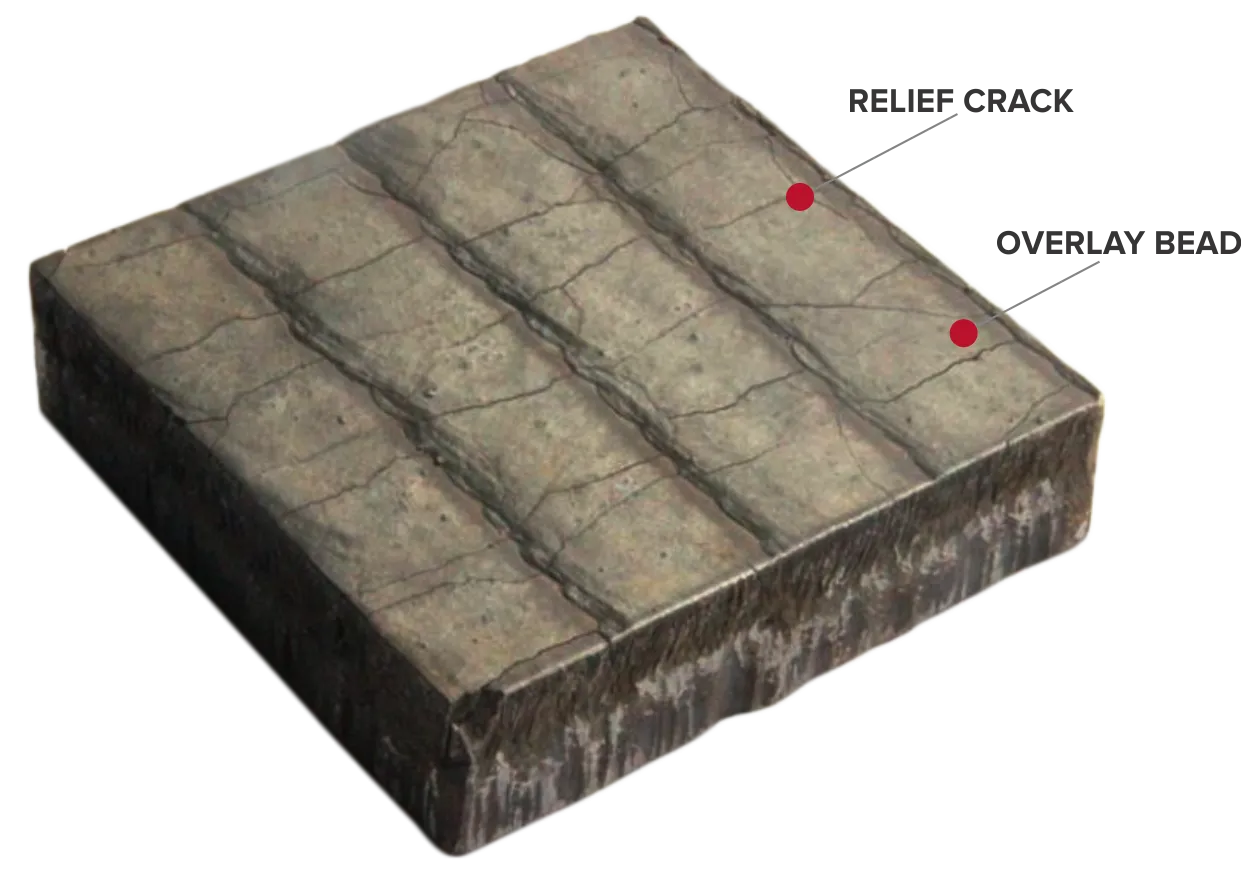

CCO Wear Plate is engineered as an economical alternative to traditional abrasion-resistant steels, with a beaded overlay surface containing beneficial hairline cracks that enhance flexibility and prevent delamination. These cracks propagate through the overlay and terminate at the fusion line, ensuring structural integrity under stress.

| Type | Overlay Material | Key Properties | Typical Thickness (Overlay) |

|---|---|---|---|

| Chromium Carbide Overlay (CCO) | Chromium carbides on mild steel base | High abrasion resistance; good for sliding and low-impact wear; up to 30x longer life than mild steel | 1/8" to 1/4" |

| Complex Carbide Overlay | Refined complex carbides (e.g., chromium + niobium) | Enhanced toughness, corrosion resistance, and temperature stability (up to 1000°F); ideal for high-stress applications | 1/8" to 3/16" |

| Borocarbide Overlay | Boron-enhanced carbides | Superior hardness for extreme erosion and metal-to-metal wear; heat-resistant up to 1200°F | 1/16" to 1/8" |

| Super-Clad or Premium CCO | Advanced CCO with additives for refined carbides | Balances abrasion and impact; lasts 20x longer than manganese steel in some cases | 3/16" to 1/2" |

| Parameter | Details |

|---|---|

| Hardness | 58-62 HRC (varies by weld thickness) |

| Temperature Limit | Up to 1100°F |

| Wear Resistance | Superior against abrasion, fretting, cavitation, and particle erosion |

| Impact Rating | Mild to moderate |

| Sizes | Custom sizes available upon request |

| Base Material | Mild steel substrate with chromium carbide overlay |

| Grades | Alloying Elements | Description | Hardness |

|---|---|---|---|

| WAT ECO | Cr, C, Mn | Suitable for all mild abrasion & impact | 55 - 57 HRC |

| WAT STD | Cr, C, Mn, Si, B | Suitable for moderate abrasion & impact | 58 - 60 HRC |

| WAT PR | Cr, C, Mn, Si, B, W, V | Suitable for resistant of high abrasion and moderate pressure & impact | 61 - 62 HRC |

| WAT ER | Cr, C, Mn, Si, W, Nb | Suitable for resistant of high abrasion and pressure & impact | 63 - 65 HRC |

| WAT HT | Cr, C, Mn, Si, W, Nb, Mo | Suitable for high abrasion / impact and high temperature up to 600 deg Celsius | 66 - 67 HRC |

The overlay surface of CCO plate will consist of a series of beads with numerous hairline cracks in them. These properly spaced crosscheck cracks are a natural phenomenon and are beneficial to the material. The cracks propagate through the overlay and end at the fusion line.

Plasma burning, air arc, abrasive saw or water jet.

Our CCO overlay plate can be joined by welding the substrate to substrate using 309 weld wire/rod.

Using a press brake, forming should be perpendicular to the weld pass direction. Plate rolling should be performed in the directions of the overlay beads.

Overlay plates are versatile and tailored to specific wear challenges. Below are examples across industries.

Used in chutes, hoppers, and conveyor systems in mining or aggregate processing. CCO plates excel here, resisting material flow that erodes surfaces.

Ideal for high-stress areas like bucket lips and crusher liners in quarrying, where deep scratching and tearing occur.

Suitable for hammer mills and moderate-duty crushers. Products like Super-C® handle combined impact and sliding without cracking.

Applied in heavy-duty equipment like dragline buckets in mining, providing toughness against severe blows and abrasion.

In coal-fired power plants or incinerators, borocarbide overlays protect boiler tubes and ash handling equipment from heat and particle erosion.

In corrosive environments like acidic mining slurries or chemical processing, overlays provide dual protection against wear and chemical attack.

For fabrication, these plates can be cut via plasma, water jet, or abrasive saw; welded using compatible rods (e.g., 309 for CCO); and bent perpendicular to weld beads for forming.

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0