High-performance Wear Solution

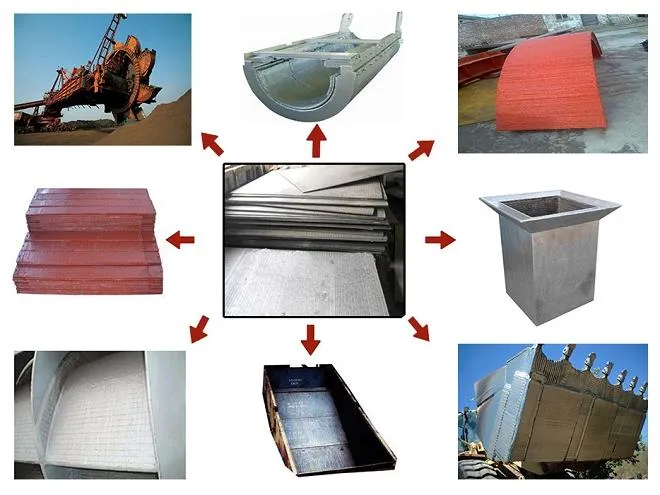

Elevate your operations with niobium carbide overlay wear plate, delivering hrc58-62 hardness and 5-10x longer life against abrasion in mining, cement, and steel sectors.

High-performance Wear Solution

Elevate your operations with niobium carbide overlay wear plate, delivering hrc58-62 hardness and 5-10x longer life against abrasion in mining, cement, and steel sectors. this customizable hardfacing overlay solves erosion and impact issues, ensuring minimal downtime, easy fabrication, and cost savings through robust, corrosion-resistant performance in chutes, hoppers, and pulverizers.

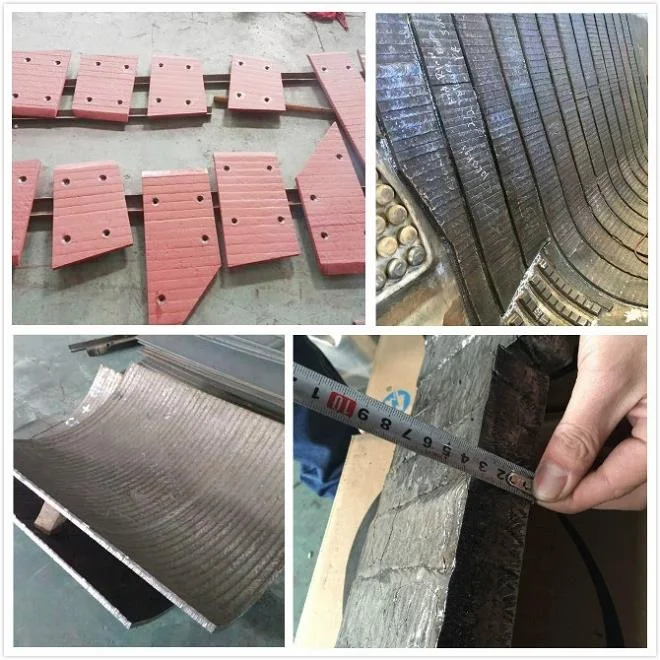

This product combines a mild steel base with a high-chromium carbide overlay, delivering superior durability and longevity in abrasive environments.

This wear plate is fabricated by cladding mild steel with specialized hardfacing wires via open-arc welding, resulting in a robust overlay that resists abrasion, impact, and corrosion. It's ideal for heavy-duty applications in material handling, offering up to 5-10 times the service life of standard mild steel and 3-5 times that of typical wear plates.

| Item | Details |

|---|---|

| Product Name | Overlay Wear Plate |

| Type | LWP235 |

| Overlay Carbide | High chromium carbide |

| Chemical Composition | C: 4~6%, Cr: 15~20%, Mn: |

| Welding Process | Open arc |

| Base Material | Mild steel(Other material available on request) |

| Hardness of Coating Surface | HRC58-62 |

| Carbide Content | >40% |

| Structure | Primary carbides and eutectic carbides of the M7C3 type in austenitic matrix |

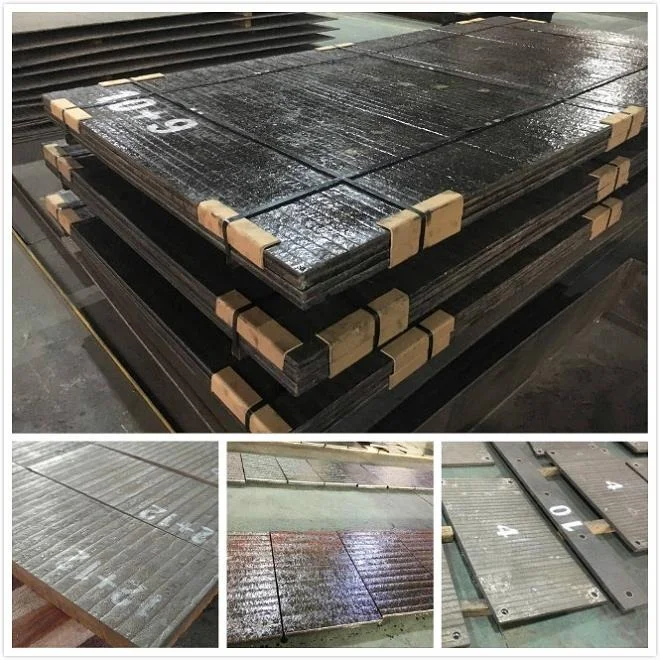

| Thickness (Overlay + Base) | 5+3, 6+4, 8+5, 8+8, 10+10, 12+12, 12+17 mm |

| Standard Size | 1400×2880MM, 1500×3000MM, 2000×3000MM (Other size available on request) |

| Impact Resistance | Low and Moderate impact |

| Production Capacity | 3500-4500 Sqm per month |

HARD FACING

Niobium carbide overlay wear plates are known for their exceptional hardness and wear resistance, making them ideal for various applications in the iron and steel industry.

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99