Tag#for BOILER PIPE PROTECTION Get: 6 results

Heat resisting stainless steel pipes are premium austenitic alloys tailored for extreme thermal service, providing unmatched boiler pipe protection via robust resistance to oxidation, carburization, and sulfidation.

Stainless steel composite pipes deliver unmatched corrosion resistance and wear protection for boiler pipe systems and industrial applications, combining inner stainless steel layers for erosion defense with outer carbon steel for structural strength.

Wear-resistant hardfacing liner plates deliver elite abrasion and corrosion defense for boiler linings and pipelines, overlaid with crc alloys for 5x longer life against erosive slurries, impacts, and chemicals up to 650°c.

Astm a182 ss 310/310s flanges deliver exceptional corrosion resistance and erosion protection for high-temperature pipelines and boilers.

Astm a790 s32750 super duplex stainless pipes offer superior corrosion and erosion resistance for offshore pipelines and boilers, blending 25% cr, 7% ni, and 4% mo for pitting resistance up to pren 40+ in chloride-rich seas.

Silicon carbide ceramic wear-resistant pipes deliver elite erosion and corrosion protection for boilers and pipelines, with ultra-hard sic linings that outlast steel 10x against abrasives, chemicals, and heat up to 1200°c.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

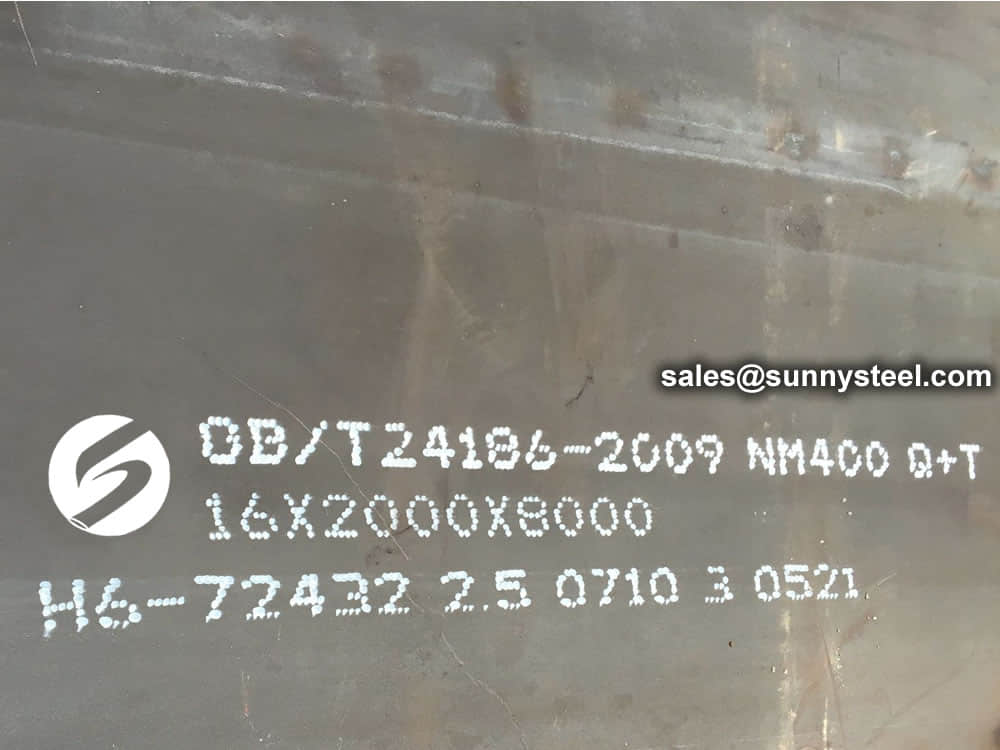

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.