High-strength Duplex Pipes For Boiler Pipe Protection And Corrosion Resistance In Harsh Marine Environments

Astm a790 s32750 super duplex stainless pipes offer superior corrosion and erosion resistance for offshore pipelines and boilers, blending 25% cr, 7% ni, and 4% mo for pitting resistance up to pren 40+ in chloride-rich seas.

High-strength Duplex Pipes For Boiler Pipe Protection And Corrosion Resistance In Harsh Marine Environments

Astm a790 s32750 super duplex stainless pipes offer superior corrosion and erosion resistance for offshore pipelines and boilers, blending 25% cr, 7% ni, and 4% mo for pitting resistance up to pren 40+ in chloride-rich seas.

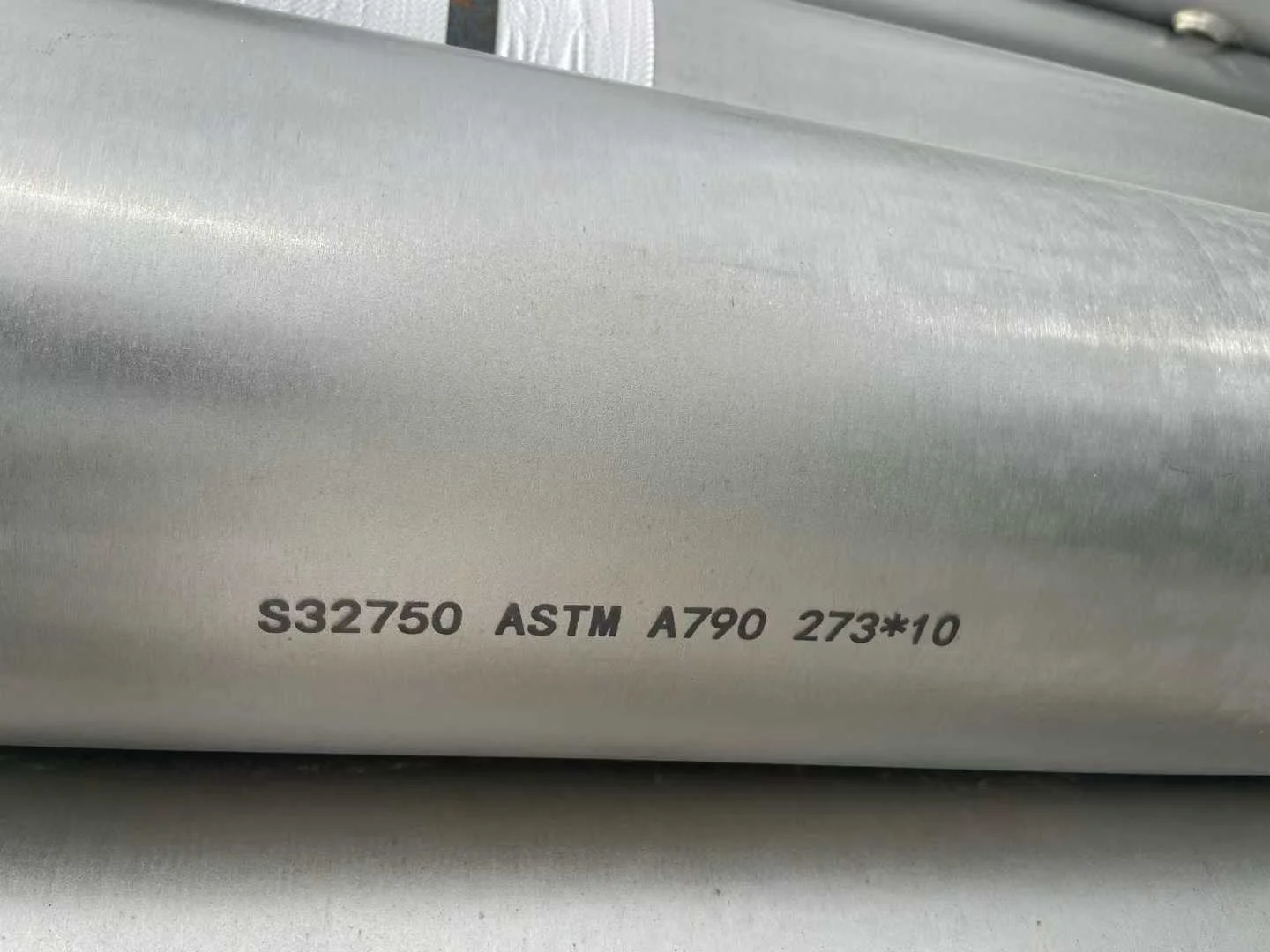

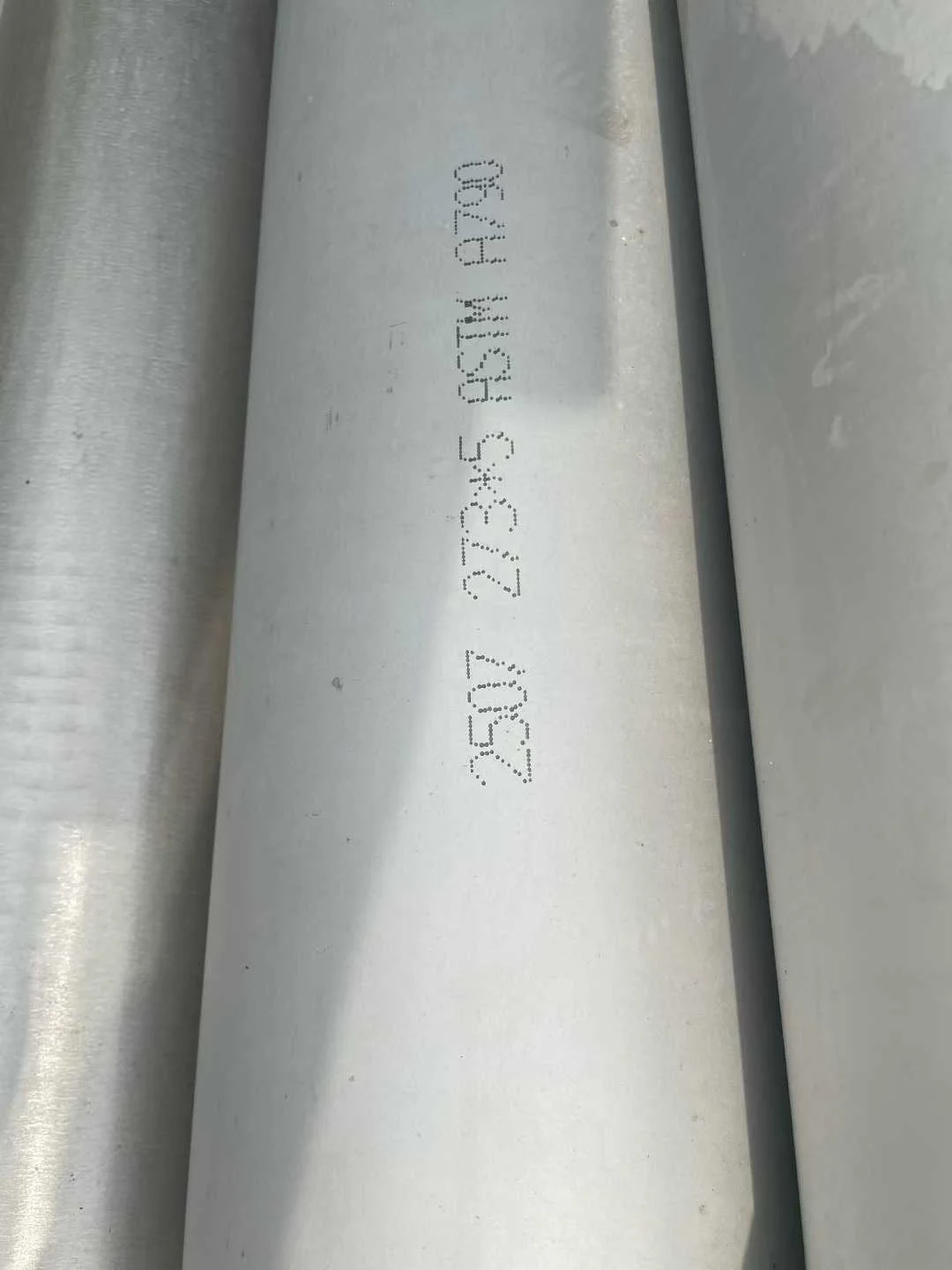

ASTM A790 S32750 Super Duplex Stainless Pipes embody peak performance in duplex metallurgy, merging austenitic and ferritic phases for exceptional boiler pipe protection and pipeline corrosion protection against the perils of chloride stress cracking, pitting, and crevice corrosion in saline, acidic, or H2S-laden streams. With UNS S32750 designation—featuring 24-26% Cr, 6-8% Ni, 3-5% Mo, and 0.2-0.8% N—these pipes attain yield strengths of 450-550 MPa and tensile up to 800 MPa, outstripping 316L in sour service (NACE MR0175/ISO 15156 compliant) for subsea umbilicals, firewater lines, and desalination intakes up to 300 bar and 250°C.

These corrosion resistant pipes directly neutralize threats like boiler pipe grinding from cavitation in pumps, sigma phase embrittlement under heat, and microbial-induced corrosion in biofilms, dovetailing with searches for "industrial pipeline protection solutions" or "boiler corrosion resistant fittings." Their balanced microstructure (50/50 austenite/ferrite) delivers 2x toughness over super austenitics, with low thermal expansion (13 x 10^-6/K) curbing distortion in welds, while PREN >40 fortifies against seawater pitting (CPT >80°C). In offshore platforms, S32750 pipes conduit produced fluids sans sulfide cracking; in chemical plants, they ferry acetic acid streams; and in power utilities, they line seawater cooling circuits, often slashing failure rates by 70% per API 5LC metrics.

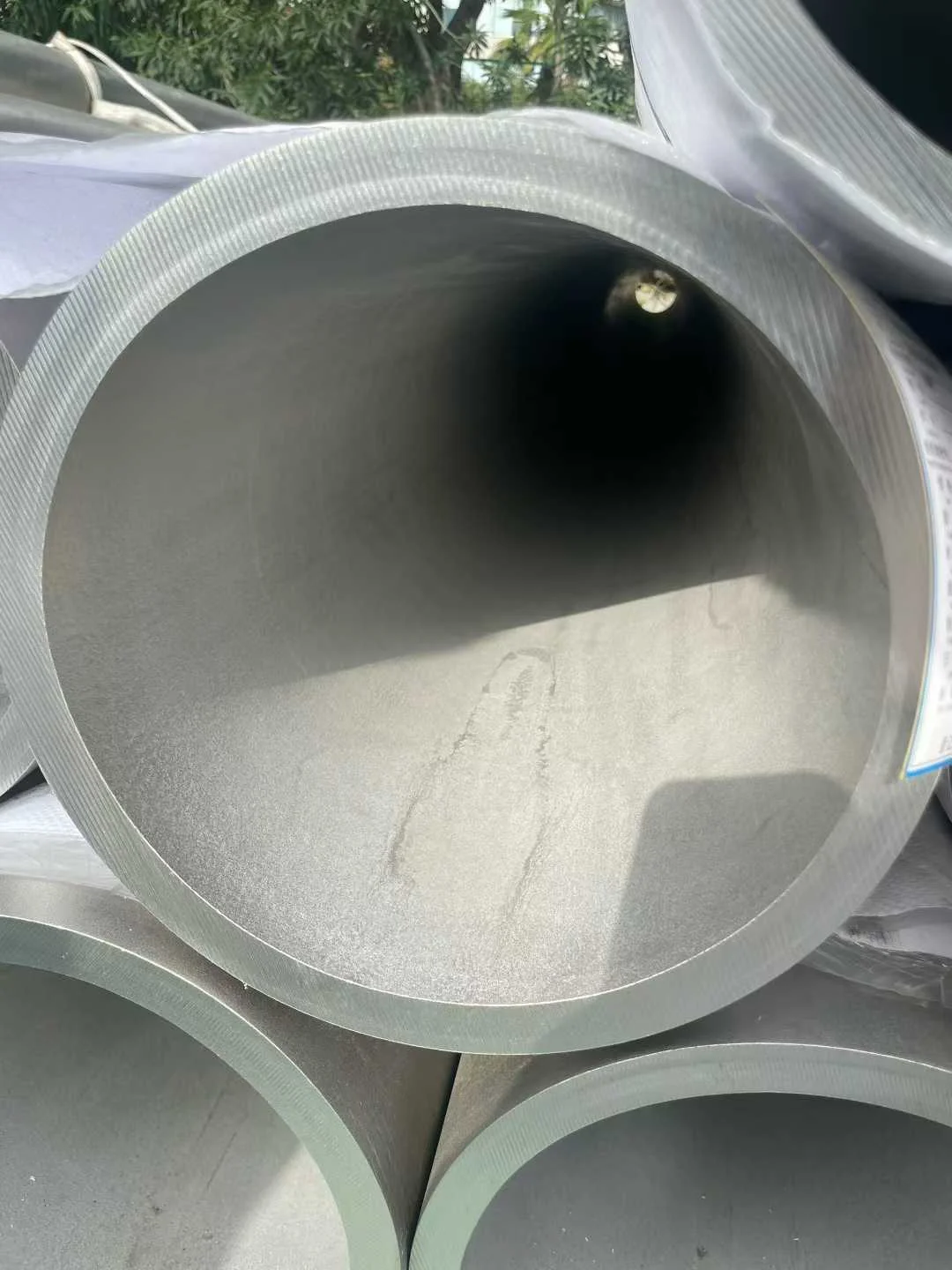

Governed by ASTM A790/ASTM A928 for seamless/welded ferritic-austenitic pipes, erosion resistant pipes span schedules SCH 10S-160, sizes 1/2"-24" (DN15-600), lengths 6-12m (or U-bent), and finishes like annealed-pickled for oxide-free surfaces. Ends include plain, beveled for GTAW/SMAW welding, or threaded for NPT connections, with hydrotesting to 1.5x design pressure and PMI verification ensuring phase balance. Eddy current/UT NDT detects flaws <5% wall, while optional sour service annealing (1025°C WQ) boosts ductility (elongation >25%).

Core attributes: density 7.8 g/cm³, thermal conductivity 14 W/m·K, and impact toughness >100J at -46°C—sparking long-tail queries like "ASTM A790 S32750 pipes for boiler erosion resistance" or "super duplex erosion resistant pipes PN100." In LNG terminals, they resist cryogenic spills; in pulp mills, they defy bleach corrosion; and in renewables, they armor tidal energy ducts, validated by ASTM G48 pitting tests (<0.1mm depth). Suppliers furnish spooled lines with FEA stress modeling, plus mill certs for traceability.

For engineers eyeing "boiler pipeline wear solutions," S32750 pipes unlock ROI: 40% weight savings over carbon steel, weldable with ER2594 filler for mismatch-free joints, and recyclable for green credentials. Pair with duplex flanges or valves for sealed systems. Procure bend tests or spool quotes to shield your conduits from corrosive cascades.

| Feature | S32750 Duplex Edge | Application Gain |

|---|---|---|

| Pitting Resistance | PREN 40+, CPT 90°C+ | Flawless in seawater fire mains 10 yrs |

| Yield Strength | 550 MPa min, fatigue limit 300 MPa | Lighter walls for deepwater risers |

| SCC Immunity | Ferrite islands trap H atoms | Sour gas safe per NACE up to 10% H2S |

| Weldability | Low dilution, no PWHT needed | 50% faster fab in offshore tie-ins |

| Element | Min (%) | Max (%) |

|---|---|---|

| Carbon (C) | - | 0.030 |

| Silicon (Si) | - | 0.80 |

| Manganese (Mn) | - | 1.20 |

| Phosphorus (P) | - | 0.030 |

| Sulfur (S) | - | 0.020 |

| Chromium (Cr) | 24.0 | 26.0 |

| Nickel (Ni) | 6.0 | 8.0 |

| Molybdenum (Mo) | 3.0 | 5.0 |

| Nitrogen (N) | 0.24 | 0.32 |

| Copper (Cu) | - | 0.50 |

| Iron (Fe) | Balance | - |

| Property | Value |

|---|---|

| Tensile Strength | 800 MPa (116 ksi) |

| Yield Strength (0.2% offset) | 550 MPa (80 ksi) |

| Elongation | 25% |

| Hardness (Brinell) | ≤ 290 HB |

| Impact Toughness (Charpy V-notch, min) | 80 J at -46°C |

ASTM A312 TP347H Stainless Steel Pipe

Sort:100

Heat resistant stainless steel pipe

Sort:0

Stainless steel pipes for oil cracking

Sort:0

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99