Tag#for Boiler Pipe Shield Get: 4 results

Defend your boiler pipes and industrial pipelines with chromium carbide overlay wear plate, offering hrc58-62 hardness and up to 1100°f resistance to combat erosion, corrosion, and abrasion. this cost-effective cladding solution extends equipment life 5-10x, minimizes downtime in mining and power sectors, and ensures seamless integration for reliable, low-maintenance protection against harsh environments.

Fortify your boiler systems with cco pipe corrosion protection, delivering hrc55-62 hardness and up to 800°c resistance to erosion and chemical attacks. this chromium carbide overlay pipe extends service life 4-5x in mining slurries and power plant ash lines, minimizing leaks and downtime while ensuring seamless weldability for easy retrofits.

Strengthen your boiler infrastructure with cco wear tube corrosion protection, featuring hrc60 hardness and up to 800°c thermal stability to combat erosion and chemical degradation.

904l stainless steel pipe (uns n08904, en 1.4539) is a high-alloyed, low-carbon austenitic grade renowned for its exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking in aggressive environments.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

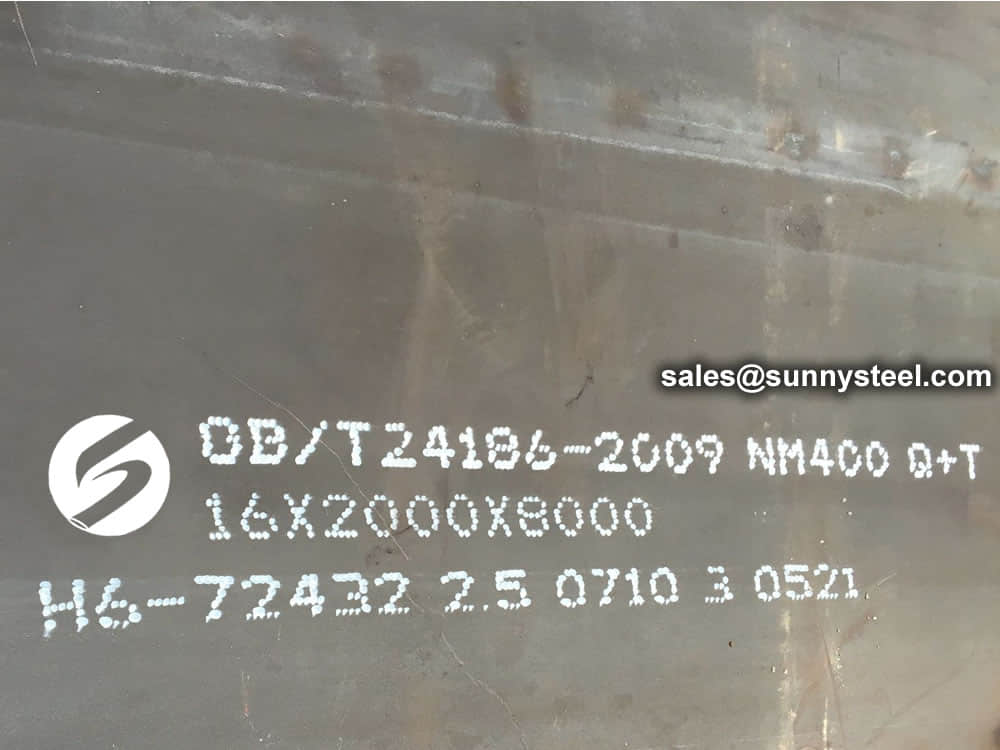

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.