High-alloy Austenitic Stainless Tubing For Superior Pipeline Durability In Acidic And High-temp Environments

904l stainless steel pipe (uns n08904, en 1.

High-alloy Austenitic Stainless Tubing For Superior Pipeline Durability In Acidic And High-temp Environments

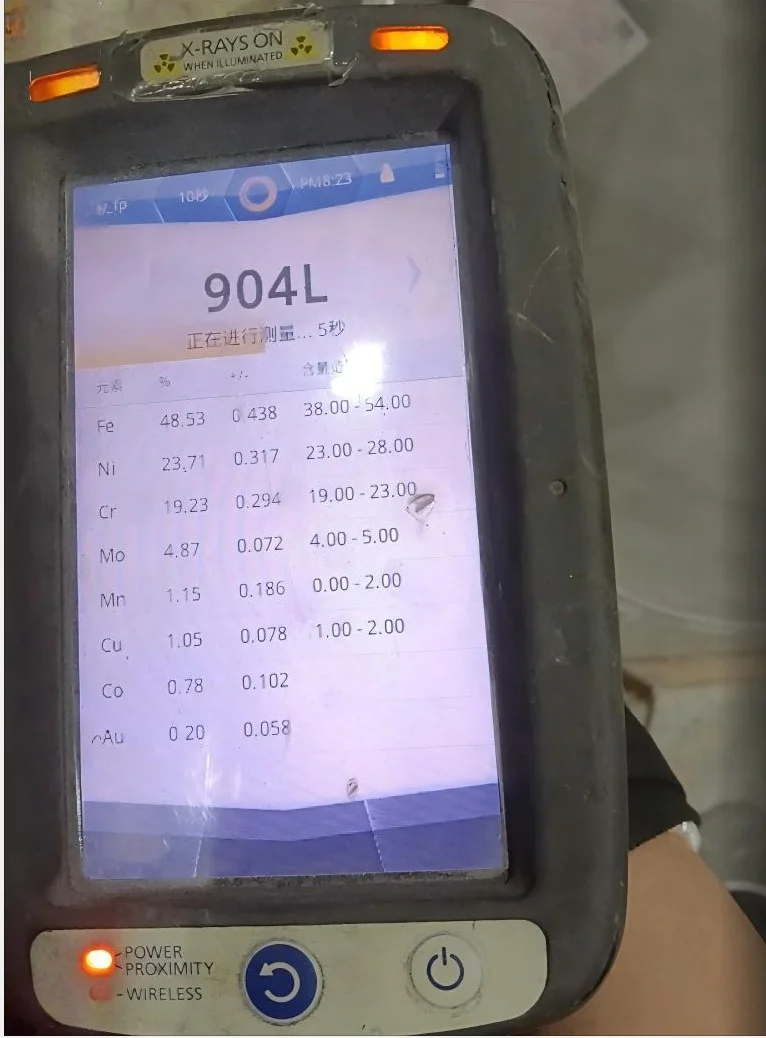

904l stainless steel pipe (uns n08904, en 1.4539) is a high-alloyed, low-carbon austenitic grade renowned for its exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking in aggressive environments.

Enriched with copper, molybdenum, and high nickel/chromium levels, it's ideal for seamless, welded, or ERW pipes in chemical processing, desalination, and marine applications. As of November 2025, demand surges in sustainable energy sectors like hydrogen transport due to its durability in chloride-rich and acidic conditions, offering 2-3x the service life of 316L in harsh settings while maintaining formability and weldability.

In the demanding realm of steam generation and fluid transport, 904L pipe corrosion protection stands as a cornerstone for safeguarding boiler pipe shield against the insidious effects of pitting, crevice corrosion, and stress corrosion cracking (SCC) prevalent in high-chloride, acidic conditions. This high-alloy austenitic stainless pipeline, designated UNS N08904 or EN 1.4539, derives its prowess from a meticulously balanced composition—23-28% nickel for SCC resistance, 19-23% chromium for pitting equivalence ratio (PREN >35), 4-5% molybdenum for enhanced chloride tolerance, and 1-2% copper for superior performance in reducing acids like sulfuric and phosphoric. Low carbon (erosion resistance in turbulent boiler feeds where velocities exceed 10 m/s.

For operators searching "industrial pipeline protection solutions," 904L's non-magnetic, formable nature allows tight bends in complex routing, while its yield strength of 220 MPa supports pressures up to 2,000 psi without deformation. In desalination plants, it lines evaporator tubes against warm seawater erosion, outperforming 316L by 2-3x in lifespan due to copper's role in countering biofouling and crevice formation. Power sector applications leverage its thermal stability up to 400°C for superheater lines, where it resists oxidation and particulate impingement from fly ash, directly addressing boiler tube wastage that plagues conventional alloys. Global standards like ASTM A312 and ASME SA312 mandate its use in sour service (NACE MR0175), preventing sulfide stress cracking in H2S-exposed pipelines—a growing concern in 2025's hydrogen infrastructure boom.

Compared to duplex grades like 2205, 904L offers better weldability without pre-heat, using ERNiCrMo-3 filler for TIG/MIG processes, and its elongation >35% facilitates expansion joints in dynamic boiler setups. This versatility extends to pharmaceutical piping, where its low carbon purity ensures no contamination in acetic acid reactors, aligning with FDA-compliant cleanability.

The engineering backbone of stainless pipeline solutions like 904L tubing is its rigorous specs, tailored for corrosion protection in erosive boiler environments. With a density of 8.00 g/cm³ and modulus of elasticity at 190 GPa, it maintains structural rigidity under cyclic thermal loads, while hardness ≤90 HRB prevents galling during assembly. Solution annealing at 1090-1175°C followed by rapid quenching optimizes the austenitic microstructure, enhancing acid resistant tubing against uniform corrosion in pH 1-10 ranges—vital for flue gas desulfurization (FGD) lines handling sulfuric byproducts.

Mechanical prowess includes tensile strengths of 490-700 MPa, enabling seamless pipes (OD 4-219 mm, WT 0.5-20 mm) per ASTM A312 for high-pressure service, or welded variants up to 1219 mm OD for large-diameter boiler headers. Non-destructive testing (ultrasonic, hydrostatic at 2x pressure) and PMI ensure defect-free delivery, with flattening and reverse bend tests confirming ductility for cold forming. In erosion-prone applications, its PREN >35 metric—superior to 316L's 24—quantifies resistance to localized attacks, as validated by ASTM G48 pitting tests showing critical temperatures >60°C in 6% FeCl3 solutions.

| Property | Value | Benefit for Boiler Protection |

|---|---|---|

| Pitting Resistance (PREN) | >35 | Outperforms 316L in chloride steam lines |

| SCC Threshold | High Ni (23-28%) for >1000 ppm Cl | Prevents cracking in desalination boilers |

| Acid Tolerance | Excellent in H2SO4 up to 98% | Shields FGD pipes from erosion-corrosion |

| Thermal Limit | 400°C continuous | Resists oxidation in superheaters |

| Weldability | No pre-heat; ERNiCrMo-3 filler | Seamless retrofits for pipeline lining |

These metrics position 904L pipe as a proactive boiler pipe shield, solving chronic degradation for enhanced safety and longevity.

Producing 904L pipe corrosion protection involves hot extrusion for seamless forms or ERW for welded efficiency, starting with vacuum-melted billets to achieve ultra-low sulfur (erosion resistance in boiler condensate lines prone to microbiologically induced corrosion (MIC). Custom schedules (5-160/XXS) accommodate varying thicknesses, with bright annealed finishes (ASTM B677) ensuring scale-free surfaces for sanitary applications in pharma boilers.

Tailoring for stainless pipeline needs includes nitrogen additions (up to 0.10%) for interstitial strengthening without embrittlement, or copper optimization for acetic acid vapor resistance in pulp recovery boilers. In oil & gas, NACE-compliant variants handle sour H2S, while marine desalination specifies seamless tubing for evaporator coils, resisting impingement from brine droplets. As 2025's green hydrogen push accelerates, 904L's SCC immunity supports high-purity transport lines, with formability allowing helical coils for compact heat exchangers.

Compared to super-austenitics like 254 SMO, 904L balances cost with performance, offering 20-30% savings on material while matching PREN in most acidic exposures—ideal for phased upgrades in aging boiler infrastructure.

Acid resistant tubing like 904L shines in power plant FGD systems, where it lines absorber towers against sulfuric mist erosion, extending service from 2 to 6 years in a U.S. facility retrofit—cutting $300K in annual downtime. In desalination, Saudi Arabian plants use seamless 904L pipes for multi-stage flash evaporators, withstanding 50,000 ppm chlorides at 120°C without pitting, per ASTM G150 tests showing >10x corrosion rate reduction vs. 316L.

For "boiler pipeline wear solutions," it fortifies chemical recovery boilers in pulp mills, resisting tall oil corrosion and steam erosion, with one Nordic case reporting zero failures over 5 years versus quarterly inspections on duplex alternatives. Offshore oil platforms deploy welded 904L for seawater injection lines, leveraging copper's biofouling resistance to maintain flow efficiency amid particulate abrasion.

Emerging in renewables, 904L enables hydrogen electrolyzer piping, immune to alkaline SCC, supporting 2025's net-zero goals. Field data from NACE trials confirm 2-3x longevity in reducing acids, underscoring its value in pipeline lining for resilient boiler pipe shield.

Deploying 904L pipe mirrors standard stainless workflows: Orbital TIG welding with controlled heat input (corrosion protection setups. For boiler pipe shield, expand fittings accommodate thermal growth, while threaded ends suit quick-access inspection ports in FGD ducts.

Maintenance prioritizes annual PMI and ultrasonic thickness gauging to monitor uniform corrosion, with electropolishing for sanitary renewal extending intervals 2x. In erosive boilers, integrate impressed current cathodic protection to curb external pitting, slashing remediation costs by 50%. Sustainability-wise, 904L's recyclability (>90%) and low-carbon melting support green certifications, with one desalination project reducing water loss 30% via leak-proof longevity.

Versus 316L, it cuts lifecycle expenses 25% through fewer interventions, positioning acid resistant tubing as an eco-smart choice for enduring erosion resistance in modern infrastructure.

Alloy 904 (N08904) stainless steel is a high alloy austenitic product intended for use under severely corrosive conditions. It delivers reliable performance against multiple corrosion types, making it suitable for harsh industrial environments.

Grade 904L stainless steel is a non-stabilized austenitic stainless steel with low carbon content. This high alloy variant incorporates copper to enhance resistance to strong reducing acids (such as sulphuric acid) while maintaining resistance to stress corrosion cracking and crevice corrosion. It is non-magnetic, offering excellent formability, toughness and weldability.

Notably, Grade 904L contains high amounts of expensive ingredients like molybdenum and nickel. Today, many applications previously using Grade 904L have been replaced by low-cost duplex stainless steel 2205.

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤0.020 |

| Chromium (Cr) | 19.0-23.0 |

| Nickel (Ni) | 23.0-28.0 |

| Molybdenum (Mo) | 4.0-5.0 |

| Copper (Cu) | 1.0-2.0 |

| Manganese (Mn) | ≤2.0 |

| Silicon (Si) | ≤1.0 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.035 |

| Nitrogen (N) | ≤0.10 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 490 |

| Yield Strength, min (MPa) | 220 |

| Elongation, min (%) | 35 |

| Hardness, max (HRB) | 90 |

| Feature | 904L (UNS N08904) | 316L (UNS S31603) | 304L (UNS S30403) | 254 SMO (UNS S31254) |

|---|---|---|---|---|

| Material Type | Austenitic Stainless | Austenitic Stainless | Austenitic Stainless | Super-Austenitic Stainless |

| Temperature Range | Up to 400°C | Up to 870°C | Up to 870°C | Up to 450°C |

| Notch Toughness | Excellent (High Ni) | Good | Good | Superior (High Mo/N) |

| Corrosion Resistance | Excellent (PREN >35, Cu/Mo) | Good (PREN 24) | Fair (PREN 18) | Outstanding (PREN 42) |

| Applications | Desalination, Acid Processing, FGD | Marine, Food, General Chemical | General Piping, Architectural | Seawater, Pulp Bleaching |

| Tensile Strength (MPa) | 490 (min) | 485 (min) | 485 (min) | 650 (min) |

| Yield Strength (MPa) | 220 (min) | 170 (min) | 170 (min) | 300 (min) |

| Key Advantage | Reducing acid/SCC resistance | Cost-effective chloride resistance | Versatile general use | Ultra-high pitting resistance |

ASTM A312 TP347H Stainless Steel Pipe

Sort:100

Heat resistant stainless steel pipe

Sort:0

Stainless steel pipes for oil cracking

Sort:0

S32750 ASTM A790 Stainless Pipe

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99