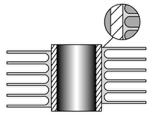

Stainless steel fin tubes are a type of heat exchanger tube that have fins attached to the outer surface.

Download PDF

Plain Stainless Steel Tubes will be procured for finning, duly Hydro Tested and Eddy Current Tested as per material specification and code, from plain tube manufacturers only, as per customer requirement. If customer require, we will procure plain Stainless Steel Tubes, duly inspected, approved and released by customer or Third Party Inspection Agency, at plain Tubes manufacturer's end.

These fins increase the surface area of the tube, allowing for more efficient heat transfer between the fluid inside the tube and the surrounding environment.

Plain stainless steel tubes will be procured for finning, duly hydro tested and eddy current tested as per material specification and code, from plain tube manufacturers only, as per customer requirement.

If customer require, we will procure plain stainless steel tubes, duly inspected, approved and released by customer or third party inspection agency, at plain tubes manufacturer's end.

| Specifications | Details |

|---|---|

| Standard | ASTM A213 |

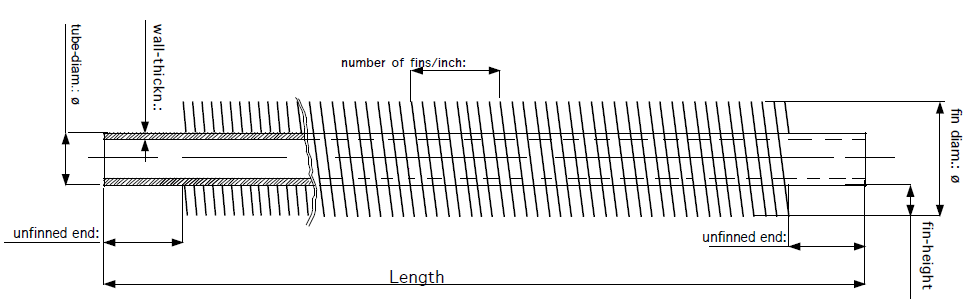

| Fin Height | 1/4” - 1” Inch |

| Tube Size | 5/8” - 2” Inch |

| Fin Type | G, Kl & L, Ll |

| Tube Length | - 60” Feet |

| Wall Thickness | 0.072”Inch |

| FPI | 4 - 13 |

| Finishing | Tubes can be supplied in mechanical polished with various grits like at 80, 120, 240, 320, 400, 600 grit and mirror polished. |

Stainless Steel Low Fin Tubes are available with exact lengths required by customer, maximum upto 20 Meters.

Stainless Steel Low Finned Tubes are available with plain portion at both ends, as per customer specification.

Stainless Steel Fin Tubes are available with Intermediate landings (plain portion for baffle sheet support), as per customer requirement.

Stainless Steel Fin Tubes will be supplied, duly Hydro Tested, after finning. Stainless Steel Fin Tubes will be supplied in "As Finned Temper".

We shall supply Stainless Steel Fin Tubes, duly inspected and approved by Customer or any Third Party Inspection Agency, as per customer specific requirement, at our end before dispatch.

We shall provide MTC along with our supply documents.

With the overall success of the transfer of heat, Finned Tubing is wildly popular in the oil and gas industry. As liquid flows through the inside of a finned tube there is often air or some other gas flowing outside of the tube. Most Finned Tube heat exchangers are crossflow. They act as a great heat exchanger when one of the transfer variables is gas or air. Extruded Fin Tubes, tubes manufactured with extrusion that is radially crushed on the lining, often provide a highly efficient surface area for a heat exchanger tube. The kinds of transfers these tubes are often used for in this sector include transfer from liquid to gas, thermal fluid to air, and vapor to gas.

Stainless steel fin tubes are commonly used in various industries, including HVAC (heating, ventilation, and air conditioning), refrigeration, power generation, and petrochemical plants. They are particularly suitable for applications where corrosion resistance and durability are important.

| Properties | Value | Explanation |

|---|---|---|

| Tensile Strength | > 500 MPa | Suitable for Mechanical Stress and High Pressures |

| Corrosion Resistance | High (e.g., > 90%) | Prevents Corrosion and Damage. |

| Thermal Conductivity | Moderate (15-30 W/m·K) | Fins Provide Excellent Heat Transfer Efficiency. |

| Service Life | 15-30 years | Long-term Performance in a Variety of Applications. |

| Cleanability | Easy to maintain | Smooth Surfaces Help You Clean Quickly. |

| Design Flexibility | Flexible Configuration | Readily Adjusts to Many System Needs. |

| Working Steps | Explanation |

|---|---|

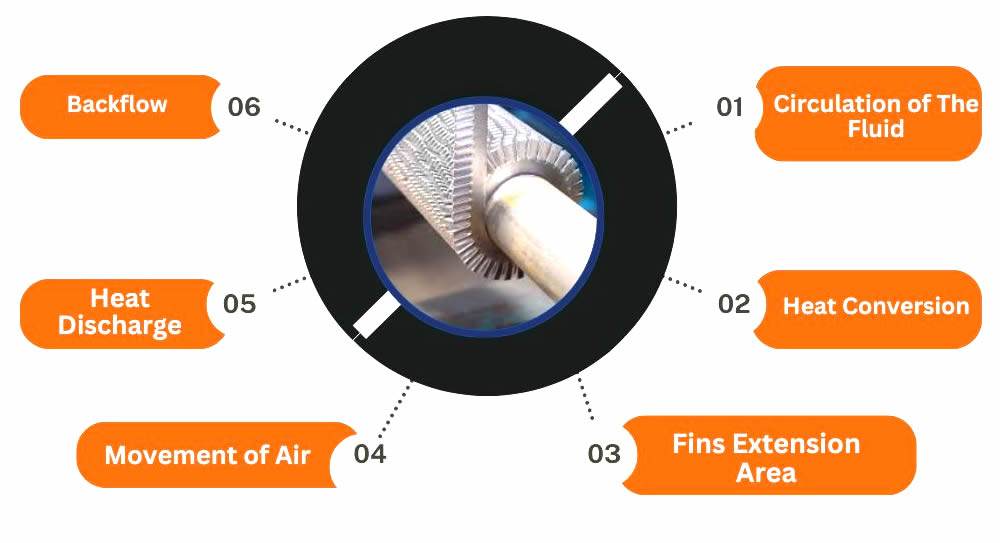

| Circulation of The Fluid | A Heated Liquid Passes Through Stainless Steel Tube |

| Heat Conversion | Heat Moves From the Fluid to the Surface of the Tube. |

| Fins Extension Area | The Surface Area for Heat Exchange is Increased by Fins on Tubes. |

| Movement of Air | Air is Circulated Over Fins by Forced or Natural Convection. |

| Heat Discharge | The Atmosphere is Filled With Heated Air. |

| Backflow | Re-entering the Cycle, Cool Fluid is Heated Again. |

| Feature | Extruded Fins Tube | Embedded Fins Tube |

|---|---|---|

| Method Of Manufacturing | From the Tube Material, Fins Are Extruded. | In the Tube Wall, Fins Are Cast or Machined. |

| Efficiency Of Heat Transfer | High Because of the Fins' Huge Surface Area. | Excellent, but It Could Not Be as High as Extruded. |

| Structural Integrity | Good Connection Between the Tube and Fins. | Integral Design: Fins Are a Component of the Tube |

| Cost | Generally Greater as a Result of Sophisticated Production. | Usually Less Expensive |

| Weight | Due to the Fin Material, Slightly Heavier. | Lighter Since the Tube Material Contains Fins. |

| Fouling Resistance | Fewer Chances to Prompt Problems; More Easily Cleaned. | Can Build Up Deposits and Might Need Extra Upkeep. |

| Uses | Frequently Seen in Heat Exchangers | Utilized in a Number of Applications including HVAC |

Stainless steel fin tubes are available from manufacturers and distributors specializing in heat exchanger products. It is important to specify the specific requirements, such as dimensions, material grade, and fin type, when purchasing stainless steel fin tubes.

Stainless Steel Low Fin Tubes are available with exact lengths required by customer, maximum upto 20 Meters.

Stainless Steel Low Finned Tubes are available with plain portion at both ends, as per customer specification.

Stainless Steel Fin Tubes are available with Intermediate landings (plain portion for baffle sheet support), as per customer requirement.

Stainless Steel Fin Tubes will be supplied, duly Hydro Tested, after finning. Stainless Steel Fin Tubes will be supplied in "As Finned Temper".

We shall supply Stainless Steel Fin Tubes, duly inspected and approved by Customer or any Third Party Inspection Agency, as per customer specific requirement, at our end before dispatch.

We shall provide MTC along with our supply documents.

With the overall success of the transfer of heat, Finned Tubing is wildly popular in the oil and gas industry. As liquid flows through the inside of a finned tube there is often air or some other gas flowing outside of the tube. Most Finned Tube heat exchangers are crossflow. They act as a great heat exchanger when one of the transfer variables is gas or air. Extruded Fin Tubes, tubes manufactured with extrusion that is radially crushed on the lining, often provide a highly efficient surface area for a heat exchanger tube. The kinds of transfers these tubes are often used for in this sector include transfer from liquid to gas, thermal fluid to air, and vapor to gas.

Stainless steel fin tubes are made from stainless steel, which offers excellent corrosion resistance and high strength. Different grades of stainless steel can be used depending on the specific application requirements.

300 series stainless is a particularly popular choice when it comes to the manufacturing of finned tubing. Type 301 stainless steel is an austenitic chromium-nickel stainless steel that provides high strength and good ductility when cold worked. 304 stainless steel is, in the annealed condition, essentially non-magnetic and becomes slightly magnetic with the application of cold work. Type 304l stainless steel is preferred in welding applications. Type 316 stainless steel is an austenitic chromium nickel stainless steel containing molybdenum. This addition increases general corrosion resistance, improves resistance to pitting from chloride ion solutions, and provides increased strength at elevated temperatures. These are just some of the many grades of stainless steel that nks stocks in our inventory. When it comes to finned tubing, corrosion resistance can be key. That’s why customers come to us when sourcing material for this application. We’ve got you covered.

400 series stainless, on the other hand, boasts additional features that might appeal to this particular end-user. 400 series stainless, particularly 409, 430 and 439, provide improved oxidation and corrosion resistance compared to carbon steel. When application temperatures are too high for type 409, type 439 provides good oxidation and corrosion resistance for many automotive exhaust system components and residential furnace primary heat exchangers.

| America | North America | Russia | Europe |

|---|---|---|---|

| ASTM A213/269/249 | UNS | Material No. (WNr) | EN 10216-2 Seamless / EN 10217-5 Welded |

| 304 | S30400 | 1.4301 | X5CrNi18-10 |

| 304L | S30403 | 1.4306 | X2CrNi19-11 |

| 304H | S30409 | 1.4948 | X6CrNi18-11 |

| 316 | S31600 | 1.4401 | X5CrNiMo17-12-2 |

| 316L | S31603 | 1.4404 | X2CrNiMo17-2-2 |

| 316Ti | S31635 | 1.4571 | X6CrNiMoTi17-12-2 |

| 317L | S31703 | 2.4660 | FeMi35Cr20Cu4Mo2 |

Transferring heat from a hot fluid into a colder fluid through a tube wall is the reason many of us use finned tubes.

But you may ask, what is the major advantage of using a finned tube? Why can’t you just use a regular tube to make this transfer? Well you can but the rate will be much slower.

By not using a finned tube the outside surface area is not significantly greater than the inside surface area. Because of that, the fluid with the lowest heat transfer coefficient will dictate the overall heat transfer rate. When the heat transfer coefficient of the fluid inside the tube is several times larger than that of the fluid outside the tube the overall heat transfer rate can be greatly improved by increasing the outside surface area of the tube.

Finned tubes increase outside the surface area. By having a finned tube in place, it increases the overall heat transfer rate. This then decreases the total number of tubes required for a given application which then also reduces overall equipment size and can in the long-run decrease the cost of the project. In many application cases, one finned tube replaces six or more bare tubes at less than 1/3 the cost and 1/4 the volume.

For applications that involve the transfer of heat from a hot fluid to a colder fluid through a tube wall, fin tubes are used. Usually, for an air heat exchanger, where one of the fluids is air or some other gas, the air side heat transfer coefficient will be much lower, so additional heat transfer surface area or a fin tube exchanger is very useful. The overall pattern flow of a finned tube exchanger is often crossflow, however, it can also be parallel flow or counterflow.

Fins are used to increase the effective surface area of heat exchanger tubing. Furthermore, finned tubes are used when the heat transfer coefficient on the outside of the tubes is appreciably lower than that on the inside. In other words, heat transferred from liquid to gas, vapor to gas, such as steam to air heat exchanger, and thermic fluid to air heat exchanger.

The rate at which such heat transfer can occur depends on three factors – [1] the temperature difference between the two fluids; [2] the heat transfer coefficient between each of the fluids and the tube wall; and [3] the surface area to which each fluid is exposed.

A finned tube exchanger typically has tubes with fins attached to the outside. Usually, there will be some liquid flowing through the inside of the tubes and air or some other gas flowing outside the tubes, where the additional heat transfer surface area due to the finned tube increases the heat transfer rate. In a crossflow fin tube exchanger, the fins will typically be radial fins and they’ll either be circular or square in shape.

By not using a finned tube, the outside surface area is not significantly greater than the inside surface area. Because of this, the fluid with the lowest heat transfer coefficient will dictate the overall heat transfer rate. When the heat transfer coefficient of the fluid inside the tube is several times larger than that of the fluid outside the tube, the overall heat transfer rate can be greatly improved by increasing the outside surface area of the tube.

By having a finned tube in place, it increases the overall heat transfer rate. Finned tubes increase the outside surface area. This decreases the total number of tubes required for a given application which then also reduces overall equipment size and can in the long-run decrease the cost of the project.

Finned tube heat exchangers are used in a variety of applications, and more so as industrial heat exchangers. An air heat exchanger like the evaporator coil in an air conditioning unit is typically a fin tube exchanger. Another common fin tube air heat exchanger is the car radiator. The purpose of the car radiator is to cool the hot water in the tubes with the air passing through the crossflow. On the contrary, the air conditioner evaporator coil has the purpose of cooling the air passing through it. The finned tubes that are manufactured at Kainon Boilers, use high grade carbon steel, stainless steel, copper, brass, and aluminum. Our finned tube exchangers are designed to meet the specific duty condition, temperature and pressure of the fluids.

| Type | Description | Base tube | Fin specification (mm) | ||

|---|---|---|---|---|---|

| O.D. (mm) | Fin pitch | Fin height | Fin thick | ||

| Embedded | G-type fin tueb | 16-63 | 2.1-5 | <17 | ~0.4 |

| Extruded | Single metal combined metal | 8-51 | 1.6-10 | <17 | 0.2-0.4 |

| Low fin tube t-type fin tube | 10-38 | 0.6-2 | <1.6 | ~0.3 | |

| Bamboo tube corrugated tube | 16-51 | 8-30 | <2.5 | / | |

| Wound | l/kl/ll type fin tube | 16-63 | 2.1-5 | <17 | ~0.4 |

| String | String fin tube | 25-38 | 2.1-3.5 | <20 | 0.2-0.5 |

| U-type | U-type tube | 16-38 | / | / | / |

| Welding | HF-welding fin tube | 16-219 | 3-25 | 5-30 | 0.8-3 |

| H/HH type fin tube | 25-63 | 8-30 | <200 | 1.5-3.5 | |

| Studed fin tube | 25-219 | 8-30 | 5-35 | φ5-20 | |

Fin tube boilers represent one of a number of pressurized equipment options used to heat water or convert water into steam under controlled conditions. As in a water tube boiler, water passes through boiler tubes while combustion gases remain in the shell side, passing over the tube surfaces.

Our factory is equipped with professional technical research and design personnel who can provide product optimization design and services.

Quality is the foundation of an enterprise, the company adopts the most advanced production equipment and the best management and technical personnel in the same industry, constantly improves the product technology, strictly controls every step of the processing process, and strives to meet the fierce market competition with first-class quality products, so as to keep the company at the forefront of the industry forever.

Testing instrument

Hardness tester

Drawing Machine

Component analyzer

Aluminium KL finned tube

L LL KL G production line

Production equipments

Extrusion equipment

Fin tube bending

Specific classification of finned tubes, there are lot of types of finned tubes, meanwhile also lot of new species comes up.

And so on.

The material certificate including all the tests can be provided, and also with EN10204 3.1standard.

Отопительные трубы с ребрами обеспечивают хорошую теплопередачу, благодаря абсолютно жесткой посадке плоского ребра на внутренней трубе. Наши отопительные трубы с ребрами применяются везде, где особые условия монтажа требуют использования необычных решений, например, в фасадных системах отопления, на многоярусных складах, в теплицах, при защите стеклянных куполов от запотевания и т.д., также трубы используются для отопления жилых, промышленных и складских помещений. Имеют документированную высокую степень теплоотдачи.

Ребристые трубы монтируются при помощи стандартных фитингов, либо под сварку по желанию Заказчика.

Мы изготавливаем два типоразмера ребристой трубы :

Ду32 и Ду40.

Длину трубы определяет Заказчик.

Покрытие трубы:

-грунт

-порошковая окраска

-горячий цинк.

По ценам и срокам изготовления вы можете узнать, позвонив по телефону

Ребристая труба для отопления на свинокомплексах и птицефабриках

It is fabricated with a batch of single fins that were processed by the punch press and then manually or mechanically, with a certain distance (wingspan) on the base tube.

This is the earliest fin tube fabrication with low cost and simple production process/ technology, easy to maintain. Divides into manual set and mechanical set. Manual set uses a tool that relies on the power of man to press the fins one by one. This method is limited by the pressure of the fin, so it is easy to get loose. The machine – set fin is carried on the wing piece machine. Due to the mechanical impact or liquid pressure, the pressure of the fin is high, so it can be used in a larger volume. The bonding strength between fin and tube is high and not easy to loosen. Mechanical transmission has high productivity, but the noise is large, the safety is poor, and the working conditions of the workers are not good. Although the hydraulic transmission does not have the above problem, but the equipment price is more expensive, the technical requirement to use maintenance personnel is higher, its productivity is also lower.

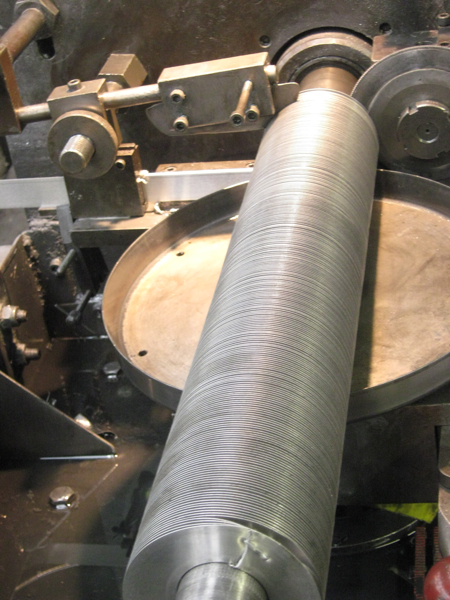

Currently HF Fin Tube is one of the most widely used helical fin tubes, you can see it as waste heat recovery in power, metallurgy, concrete, oil and gas, petrochemical, etc. When winding the steel strip around steel tube, the use of high frequency current skin effect and proximity effect on steel strip and steel pipe surface heating, until the plastic state or melt, the coil steel belt must be under pressure to complete welding. Comparing with embedded type and spot welding spiral crimped type, it is more advanced either on fin tube quality or production efficiency or automation degree.

The extruded fin is formed from an outer aluminum tube with a large wall thickness (muff), which is aligned over an inner base tube. The two tubes are pushed through three arbors with rotating discs that literally squeeze or extrude the aluminum fins up and out of the muff material in a spiral shape in one operation. Comparing with welding fin tube, dr extruded fin has higher production efficiency with low cost on material and high heat transfer. At present, it divides into copper or aluminum single metal fin tube and bi-metal composited fin tube.

Fin tube manufacturers produce a wide range of fin tubes. They are used in heat exchangers (air, water and chemically cooled) for various industries such as petroleum, petrochemical, steel, power generation and many more.

Corrosion protection processes are performed during fin tube manufacturing and the material used is corrosion resistant. Some fin tube types are:

Helical high finned tubes are used to repair air-cooled heat exchangers and are available in 5 variations

| Type | Photo | Descriptions | Properties |

|---|---|---|---|

| "KL" fin tubes |  |

After application the fin foot is knurled into the corresponding knurling on the base tube thereby enhancing the bond between the fin and tube resulting in improved heat transfer characteristics. Max. operating. temp. 260ºC | Max working temperature – 260 °C (500 °F) Atmospheric corrosion resistance – acceptable Mechanical resistance – acceptable Fin material – aluminum, copper |

| "G" fin tubes |

|

Fin strip is wound & embedded on a groove and securely locked by closing the groove with the base tube metal. This ensures maximum heat transfer at high temperatures. Max. operating temp. 450ºC |

Max working temperature – 400 °C (752 °F) Atmospheric corrosion resistance – poor Mechanical resistance – acceptable Fin material – aluminum, copper, carbon steel |

| "LL" fin tubes |

|

Manufactured in the same way as the ‘L’ fin type except that the fin foot is overlapped to completely enclose the base tube thereby giving excellent corrosion resistance. This type of tube is often used as an alternative to the more expensive extruded type fin in corrosive environments. Max. operating. temp. 180ºC | Max working temperature – 180 °C (356 °F) Atmospheric corrosion resistance – acceptable Mechanical resistance – poor Fin material – aluminum, copper |

| “L” fin tubes |

|

The strip material is subjected to controlled deformation under tension giving the optimum contact pressure of the foot of the fin onto the base tube thus maximizing the heat transfer properties. The foot of the fin considerably enhances the corrosion protection of the base tube. Max. operating. temp. 150ºC | Max working temperature – 150 °C (302 °F) Atmospheric corrosion resistance – acceptable Mechanical resistance – poor Fin material – aluminum, copper |

| Extruded fin tubes |

|

This fin type is formed from a bi-metallic tube consisting of an aluminium outer tube and an inner tube of almost any material. The fin is formed by rolling material from the outside of the exterior tube to give an integral fin with excellent heat transfer properties and longevity. Extruded fin offers excellent corrosion protection of the base tube. Max. operating. temp. 280ºC. | Max working temperature – 285 °C (545 °F) Atmospheric corrosion resistance – excellent Mechanical resistance – excellent Fin material – aluminum |

Fin foot is pre-formed into an LL shape (overlapped LL) and applied to base tube under tension.

However, foot is pre-shaped to give overlap of one foot onto another, thereby improving base tube protection and thermal contact area Fin materials: Aluminum Base tube materials: Any metallic material.

The smooth flat fins perpendicular to the tube surface give rise to very low resistance to air /gas flow and ensure that fouling is kept to a minimum. The foot of the fin is in contact with base tube and provides a complete sheathing over the finned length.

The Overlapped “L” fin design has interlocking fins that are wound together to prevent movement and separation. The fin protects the entire tubes, so the designation works well for the applications where corrosion is a factor.This type of finned tube is often used as an alternative to the more expensive extruded type fin in corrosive environments.

Fin tubes are a type of heat exchanger that is used in many different industries. These tubes have a finned surface, which increases their surface area and allows them to transfer heat more efficiently. This makes them ideal for applications where high heat transfer rates are required, such as in power plants and refrigeration systems.

Fin tubes are made from a variety of materials, including copper, aluminum, and stainless steel. They are available in a range of sizes and shapes and can be customized to meet the specific needs of each application.

One of the key benefits of fin tubes is their ability to operate efficiently at high temperatures and pressures. This makes them suitable for use in a wide range of applications, including air conditioning, heat exchangers, and radiators.

In addition to their high thermal performance, fin tubes are also durable and long-lasting. They are resistant to corrosion and can withstand the harsh environments often found in industrial settings. This makes them a cost-effective solution for many different industries.

The first actual inspection work on the fin tube heat exchanger is the raw materials inspection. Based on the ASME Code, providing material test reports for fin tube heat exchanger plates is mandatory. For other components, the marking inspection will be enough.

The Finned Tube is exposed to the outside to prevent rainwater from falling, try to keep it dry, and it should not be too close to the ground to prevent the irrigation in the greenhouse from corroding the finned tube. After the maintenance of the finned tube, the service life of the finned tube will be greatly increased.

We are a pretty proactive bunch. So, while we do charge a small fee per design to cover our costs, we absorb these costs when it is for a regular customer or where we are working jointly on a project. We also refund the fees in case it is followed by an order.

Absolutely, we can.

Applied Fin Tube is made with strip wrapped under tension around the base of the tube. Fins are welded to the base tube at the strip ends.

Pin Fin tubes are made from wire. Being cylindrical, wire has a larger area per unit of weight than the strip used in L type fin tubes. Also, due to the looped nature of the wire, less material is put on the tube than in the case of L fins. Consequently, the surface area of fins per meter of tubes is also less. However due to the superior turbulence created by the looped wire the actual heat transfer per meter of tube is significantly higher than in the case of L Type Fin Tubes. All of this together contributes to the weight differential between wire wound fin tubes and L Type Fin Tubes. In the case of similar metals, it is weighing half and in the case of Aluminium L fin vs. Steel wire fin they weigh about the same. The higher performance S5 pin fin tubes have an airside heat transfer performance per meter of tube that is 250% of the L type fin tubes.

Yes. A lot of our customer choose to supply their own pipes or tubes, however, a lot of customers ask us to supply them and we are happy to accommodate! We stock various sizes and if we don’t have what you need we can bring it in from one of our many suppliers. If you would like us to include the pipe or tube material in your order, please indicate that when you request a QUOTE.

A continuous helical fin is attached to the base tube by high frequency electric resistance welding in order to give an efficient and thermally reliable bond. Fins can be either solid or serrated (segmented). The weld produced in this process is a true forge, blacksmith weld. This type of weld is comprised of a fusion between two portions of parent metal without the introduction of a filler material. The weld is simply produced by heating the interfaces to be joined to a plastic state and applying pressure.

Used in boilers, furnaces and fired heaters for efficient heat recovery.

The main uses for high frequency welded finned tubes are in the heat recovery associated with boilers for power generation and in furnace applications for the petrochemical industry.

Our finning machines are equipped with online single or duplex cold bending equipment that can manipulate both ends of tubes in a single operation, thus ensuring exact alignment of the ends.

We do not. Our market lends itself to customer designed products, each special in itself. The number of combinations of diameter, overall length, materials and fin specs are too vast. Sunny Steel builds each finned product to each customers needs.

Finned tubes are the main components of heat exchangers. They are a series of tubes where fins have been added on the outside to increase the contact area with the outside fluid, to exchange heat and between the fluid inside the tube and the fluid outside the tube. Finned tubes are elongated aluminium cladded carbon steel flat tubes with brazed aluminium fins.

The rate at which such heat transfer can occur depends on three factors:

For any kind of information and request do not hesitate to contact our team, Sunny Steel is at your complete disposal.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.