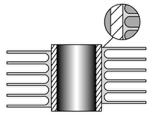

The studded fin tube is manufactured by resistance welding of studs on the bare tubes.

Download PDFStud Finned Tube, also known as nail head Finned Tube (also known as needle-shaped tube, nail-shaped ribbed tube), adopts a square or hexagonal arrangement and is equally divided into cylindrical needles welded on the surface of the heat exchange tube. The square or hexagonal reinforced heat exchange nail head tube is assembled and welded to form a high-efficiency and energy-saving needle tube heat exchange tube group.

Because the Stud Finned Tube pin rib is a cantilever structure with a compact structure, under the impact of the airflow, the pin rib vibrates, making it difficult for soot to accumulate; coupled with the strong turbulent scouring of the flue gas, the Stud Finned Tube heat exchange The element has high heat transfer efficiency and strong self-cleaning ability.

A series of studs are welded onto the surface of the steel pipe using an automatic studded tube welding machine to reinforce the heat exchange components. This process is characterized by two main features:

Compared to traditional studded tube manufacturing processes, square and hexagonal studded tubes enhance heat exchange elements through one-time welding. This innovation eliminates the issue of welding studs falling off due to stretching during tooling, resulting in a more secure weld and reduced risk of stud detachment. Various factors, such as the diameter, length, longitudinal spacing, number, and angle of inclination of the welding studs, affect the heat transfer of studded tubes and must be systematically considered for practical application.

Square and hexagonal circumferential welding and stud-shaped tubes are arranged evenly to maximize the expansion surface area, resulting in improved heat transfer coefficients. This design is particularly effective for enhancing heat transfer in high-viscosity oil products, heavy oil, and similar mediums where the stud-shaped tubes disrupt fluid flow, facilitating better heat exchange.

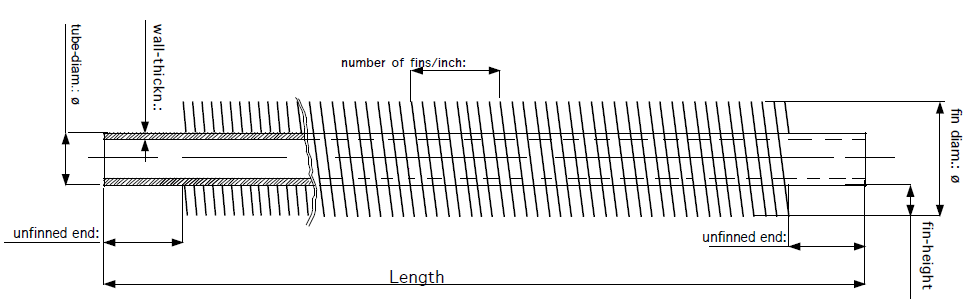

The tube ends are square cut, free of burrs, the inside is dry and blown clean, and the two ends of the extruded bimetallic finned tube are coated with varnish on the outside.

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

The structure of Stud Finned Tubes is compact. Under the impact of the airflow, the needle ribs vibrate, making it difficult for soot to accumulate; coupled with the strong turbulent scouring of the flue gas, the Stud Finned Tube heat exchange element has high heat transfer efficiency and has Strong self-cleaning ability.

Due to the high rigidity of Stud Finned Tubes, studded tubes can be used even under extreme temperature and pressure conditions.

It widely application to Economizer,Boilers, Heat ex-changers,tube bundles,Radiators, air coolers, air preheater etc.

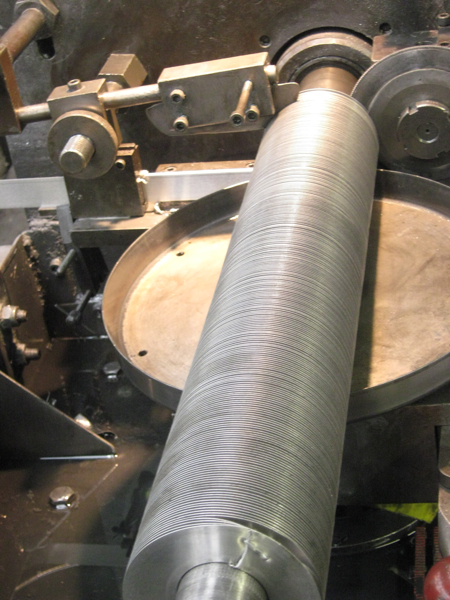

The fins are manufactured by welding of the Fin Material which is essential a stud or rod welded at base to the tube by Electrical Resistance Process.

The current is made to flow through the Tube and the base of the studs. The studs are specifically made in shapes to facilitate the welding process. The Stud; during the finning “welding” process is also mechanically pressed on the tube at the point of welding thence causing a very good mechanical bond. This type of Fin Tube find very good application in high pressure and high temperature applications. The mechanical bond is very strong and hence finds application in places where extreme mechanical load, stress is expected while during the process or cleaning etc.

These Fin Tubes find application in Finned Pipes, Air Coolers, and Heat Exchangers etc and are preferred in Industries like Petrochemical Refineries, Power Plants, Chemical Industries, and Steel Plants etc.

The nail head tube group is especially suitable for compact waste heat boilers, oil-fired, gas-fired boilers and oil heaters. Under the same heat exchange, its weight and external dimensions are greatly reduced. The anti-fouling performance of the nail head tube group is greatly improved compared with other conventional enhanced heat transfer boiler tubes. In the case of low flue gas temperature, the nail head tube can still recover waste heat economically, and has broad application prospects in heat exchange and energy saving projects.

Another one of our flagship products is the studded tube

Studded tubes are mainly used in furnaces and boilers where the surface is exposed to a very corrosive environment and dirty gases. Hence, frequent and aggressive cleaning is needed.

The steel studs are automatically resistance welded to the tube, producing high quality forge welds. Our automatic studding machines are capable of handling tube diameters from 60mm o/d to 219mm o/d and standard stud diameter of 12.7mm.

The welding process enables the combination of any grades for studs and tube: carbon, alloy, stainless steels and high nickel alloys. Alloy steel pipes are stress-relieved after studding, according to the relevant specifications for the class and grade of steel used.

Steel studded tubes are used instead of finned tubes for heat transfer in the petrochemical industry, generally in furnaces and boilers where the surface is exposed to a very corrosive environment and where very dirty gas streams require frequent or aggressive cleaning.

| Sr. No | Particulars | Range |

|---|---|---|

| 1 | Base Tube Material | Stainless Steel, Carbon Steel, Alloy Steel, Titanium , Copper, Duplex Stainless Steel, & Inconel etc. (all material in the theoretical limit) |

| 2 | Base Tube Outside Diameter | 60 mm to 200 mm |

| 3 | Base Tube Thickness | 3 mm to 12.70mm Above |

| 4 | Base Tube Length | 2000 mm Min To 15000 mm |

| 5 | Stud Material | Carbon Steel/Stainless Steel/Alloy Steel |

| 6 | Stud Thickness | 6mm to 16mm |

| 7 | Stud Density | 15.88mm or 63 Studs Per Plate Per Meter (Can Be Customized to Clients Requirements) |

| 8 | Stud Height | 12.7mm to 63.5mm |

| 9 | Bare Ends | As per Client Requirement |

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

| Materials | Grade |

|---|---|

| Carbon Steel Tubes | A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3 Gr6 Gr8, A334 Gr3 Gr6 Gr8, 09CrCuSb, DIN 17175 St35.8 St45.8, EN 10216 P195 P235 P265, GB/T3087 Gr10 Gr20, GB/T5310 20G 20MnG, |

| Alloy Steel Tubes | A209 T1 T1a,A213 T2 T5 T9 T11 T12 T22 T91,A335 P2 P5 P9 P11 P12 P22 P91,EN 10216-2 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 |

| Stainless Steel Tubes | TP304/304L, TP316/TP316L TP310/310S TP347/TP347H |

| Copper Tubes | UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes | B338 Gr 2 |

U-bent Stud fin tube is made by electrical Resistance welding specially formed Studs(Round pins ) in rows around the tube. The Studs can be supplied in a variety of Sizes and shapes. Also named pin fin tube.Stud tube have a very high heat transfer efficiency.The heat exchange efficiency is equivalent to 2-3 times that of the bare pipe. To increase the surface heat transfer coefficient of flue gas to the furnace tube.Reduce the amount of bare pipes used in these processes.

Our U-bend tubing is engineered for efficient coolant or fluid flow reversal at a 180-degree angle within confined spaces. We adhere to the highest standards, ensuring that our straight pipes meet both standard specifications and the specific requirements detailed in customer-provided drawings.

Our U-bend tubes are available in the following dimensions:

Transferring heat from a hot fluid into a colder fluid through a tube wall is the reason many of us use finned tubes.

But you may ask, what is the major advantage of using a finned tube? Why can’t you just use a regular tube to make this transfer? Well you can but the rate will be much slower.

By not using a finned tube the outside surface area is not significantly greater than the inside surface area. Because of that, the fluid with the lowest heat transfer coefficient will dictate the overall heat transfer rate. When the heat transfer coefficient of the fluid inside the tube is several times larger than that of the fluid outside the tube the overall heat transfer rate can be greatly improved by increasing the outside surface area of the tube.

Finned tubes increase outside the surface area. By having a finned tube in place, it increases the overall heat transfer rate. This then decreases the total number of tubes required for a given application which then also reduces overall equipment size and can in the long-run decrease the cost of the project. In many application cases, one finned tube replaces six or more bare tubes at less than 1/3 the cost and 1/4 the volume.

For applications that involve the transfer of heat from a hot fluid to a colder fluid through a tube wall, fin tubes are used. Usually, for an air heat exchanger, where one of the fluids is air or some other gas, the air side heat transfer coefficient will be much lower, so additional heat transfer surface area or a fin tube exchanger is very useful. The overall pattern flow of a finned tube exchanger is often crossflow, however, it can also be parallel flow or counterflow.

Fins are used to increase the effective surface area of heat exchanger tubing. Furthermore, finned tubes are used when the heat transfer coefficient on the outside of the tubes is appreciably lower than that on the inside. In other words, heat transferred from liquid to gas, vapor to gas, such as steam to air heat exchanger, and thermic fluid to air heat exchanger.

The rate at which such heat transfer can occur depends on three factors – [1] the temperature difference between the two fluids; [2] the heat transfer coefficient between each of the fluids and the tube wall; and [3] the surface area to which each fluid is exposed.

A finned tube exchanger typically has tubes with fins attached to the outside. Usually, there will be some liquid flowing through the inside of the tubes and air or some other gas flowing outside the tubes, where the additional heat transfer surface area due to the finned tube increases the heat transfer rate. In a crossflow fin tube exchanger, the fins will typically be radial fins and they’ll either be circular or square in shape.

By not using a finned tube, the outside surface area is not significantly greater than the inside surface area. Because of this, the fluid with the lowest heat transfer coefficient will dictate the overall heat transfer rate. When the heat transfer coefficient of the fluid inside the tube is several times larger than that of the fluid outside the tube, the overall heat transfer rate can be greatly improved by increasing the outside surface area of the tube.

By having a finned tube in place, it increases the overall heat transfer rate. Finned tubes increase the outside surface area. This decreases the total number of tubes required for a given application which then also reduces overall equipment size and can in the long-run decrease the cost of the project.

Finned tube heat exchangers are used in a variety of applications, and more so as industrial heat exchangers. An air heat exchanger like the evaporator coil in an air conditioning unit is typically a fin tube exchanger. Another common fin tube air heat exchanger is the car radiator. The purpose of the car radiator is to cool the hot water in the tubes with the air passing through the crossflow. On the contrary, the air conditioner evaporator coil has the purpose of cooling the air passing through it. The finned tubes that are manufactured at Kainon Boilers, use high grade carbon steel, stainless steel, copper, brass, and aluminum. Our finned tube exchangers are designed to meet the specific duty condition, temperature and pressure of the fluids.

| Type | Description | Base tube | Fin specification (mm) | ||

|---|---|---|---|---|---|

| O.D. (mm) | Fin pitch | Fin height | Fin thick | ||

| Embedded | G-type fin tueb | 16-63 | 2.1-5 | <17 | ~0.4 |

| Extruded | Single metal combined metal | 8-51 | 1.6-10 | <17 | 0.2-0.4 |

| Low fin tube t-type fin tube | 10-38 | 0.6-2 | <1.6 | ~0.3 | |

| Bamboo tube corrugated tube | 16-51 | 8-30 | <2.5 | / | |

| Wound | l/kl/ll type fin tube | 16-63 | 2.1-5 | <17 | ~0.4 |

| String | String fin tube | 25-38 | 2.1-3.5 | <20 | 0.2-0.5 |

| U-type | U-type tube | 16-38 | / | / | / |

| Welding | HF-welding fin tube | 16-219 | 3-25 | 5-30 | 0.8-3 |

| H/HH type fin tube | 25-63 | 8-30 | <200 | 1.5-3.5 | |

| Studed fin tube | 25-219 | 8-30 | 5-35 | φ5-20 | |

Fin tube boilers represent one of a number of pressurized equipment options used to heat water or convert water into steam under controlled conditions. As in a water tube boiler, water passes through boiler tubes while combustion gases remain in the shell side, passing over the tube surfaces.

Our factory is equipped with professional technical research and design personnel who can provide product optimization design and services.

Quality is the foundation of an enterprise, the company adopts the most advanced production equipment and the best management and technical personnel in the same industry, constantly improves the product technology, strictly controls every step of the processing process, and strives to meet the fierce market competition with first-class quality products, so as to keep the company at the forefront of the industry forever.

Testing instrument

Hardness tester

Drawing Machine

Component analyzer

Aluminium KL finned tube

L LL KL G production line

Production equipments

Extrusion equipment

Fin tube bending

Specific classification of finned tubes, there are lot of types of finned tubes, meanwhile also lot of new species comes up.

And so on.

The material certificate including all the tests can be provided, and also with EN10204 3.1standard.

Отопительные трубы с ребрами обеспечивают хорошую теплопередачу, благодаря абсолютно жесткой посадке плоского ребра на внутренней трубе. Наши отопительные трубы с ребрами применяются везде, где особые условия монтажа требуют использования необычных решений, например, в фасадных системах отопления, на многоярусных складах, в теплицах, при защите стеклянных куполов от запотевания и т.д., также трубы используются для отопления жилых, промышленных и складских помещений. Имеют документированную высокую степень теплоотдачи.

Ребристые трубы монтируются при помощи стандартных фитингов, либо под сварку по желанию Заказчика.

Мы изготавливаем два типоразмера ребристой трубы :

Ду32 и Ду40.

Длину трубы определяет Заказчик.

Покрытие трубы:

-грунт

-порошковая окраска

-горячий цинк.

По ценам и срокам изготовления вы можете узнать, позвонив по телефону

Ребристая труба для отопления на свинокомплексах и птицефабриках

It is fabricated with a batch of single fins that were processed by the punch press and then manually or mechanically, with a certain distance (wingspan) on the base tube.

This is the earliest fin tube fabrication with low cost and simple production process/ technology, easy to maintain. Divides into manual set and mechanical set. Manual set uses a tool that relies on the power of man to press the fins one by one. This method is limited by the pressure of the fin, so it is easy to get loose. The machine – set fin is carried on the wing piece machine. Due to the mechanical impact or liquid pressure, the pressure of the fin is high, so it can be used in a larger volume. The bonding strength between fin and tube is high and not easy to loosen. Mechanical transmission has high productivity, but the noise is large, the safety is poor, and the working conditions of the workers are not good. Although the hydraulic transmission does not have the above problem, but the equipment price is more expensive, the technical requirement to use maintenance personnel is higher, its productivity is also lower.

Currently HF Fin Tube is one of the most widely used helical fin tubes, you can see it as waste heat recovery in power, metallurgy, concrete, oil and gas, petrochemical, etc. When winding the steel strip around steel tube, the use of high frequency current skin effect and proximity effect on steel strip and steel pipe surface heating, until the plastic state or melt, the coil steel belt must be under pressure to complete welding. Comparing with embedded type and spot welding spiral crimped type, it is more advanced either on fin tube quality or production efficiency or automation degree.

The extruded fin is formed from an outer aluminum tube with a large wall thickness (muff), which is aligned over an inner base tube. The two tubes are pushed through three arbors with rotating discs that literally squeeze or extrude the aluminum fins up and out of the muff material in a spiral shape in one operation. Comparing with welding fin tube, dr extruded fin has higher production efficiency with low cost on material and high heat transfer. At present, it divides into copper or aluminum single metal fin tube and bi-metal composited fin tube.

Fin tube manufacturers produce a wide range of fin tubes. They are used in heat exchangers (air, water and chemically cooled) for various industries such as petroleum, petrochemical, steel, power generation and many more.

Corrosion protection processes are performed during fin tube manufacturing and the material used is corrosion resistant. Some fin tube types are:

Helical high finned tubes are used to repair air-cooled heat exchangers and are available in 5 variations

| Type | Photo | Descriptions | Properties |

|---|---|---|---|

| "KL" fin tubes |  |

After application the fin foot is knurled into the corresponding knurling on the base tube thereby enhancing the bond between the fin and tube resulting in improved heat transfer characteristics. Max. operating. temp. 260ºC | Max working temperature – 260 °C (500 °F) Atmospheric corrosion resistance – acceptable Mechanical resistance – acceptable Fin material – aluminum, copper |

| "G" fin tubes |

|

Fin strip is wound & embedded on a groove and securely locked by closing the groove with the base tube metal. This ensures maximum heat transfer at high temperatures. Max. operating temp. 450ºC |

Max working temperature – 400 °C (752 °F) Atmospheric corrosion resistance – poor Mechanical resistance – acceptable Fin material – aluminum, copper, carbon steel |

| "LL" fin tubes |

|

Manufactured in the same way as the ‘L’ fin type except that the fin foot is overlapped to completely enclose the base tube thereby giving excellent corrosion resistance. This type of tube is often used as an alternative to the more expensive extruded type fin in corrosive environments. Max. operating. temp. 180ºC | Max working temperature – 180 °C (356 °F) Atmospheric corrosion resistance – acceptable Mechanical resistance – poor Fin material – aluminum, copper |

| “L” fin tubes |

|

The strip material is subjected to controlled deformation under tension giving the optimum contact pressure of the foot of the fin onto the base tube thus maximizing the heat transfer properties. The foot of the fin considerably enhances the corrosion protection of the base tube. Max. operating. temp. 150ºC | Max working temperature – 150 °C (302 °F) Atmospheric corrosion resistance – acceptable Mechanical resistance – poor Fin material – aluminum, copper |

| Extruded fin tubes |

|

This fin type is formed from a bi-metallic tube consisting of an aluminium outer tube and an inner tube of almost any material. The fin is formed by rolling material from the outside of the exterior tube to give an integral fin with excellent heat transfer properties and longevity. Extruded fin offers excellent corrosion protection of the base tube. Max. operating. temp. 280ºC. | Max working temperature – 285 °C (545 °F) Atmospheric corrosion resistance – excellent Mechanical resistance – excellent Fin material – aluminum |

Fin foot is pre-formed into an LL shape (overlapped LL) and applied to base tube under tension.

However, foot is pre-shaped to give overlap of one foot onto another, thereby improving base tube protection and thermal contact area Fin materials: Aluminum Base tube materials: Any metallic material.

The smooth flat fins perpendicular to the tube surface give rise to very low resistance to air /gas flow and ensure that fouling is kept to a minimum. The foot of the fin is in contact with base tube and provides a complete sheathing over the finned length.

The Overlapped “L” fin design has interlocking fins that are wound together to prevent movement and separation. The fin protects the entire tubes, so the designation works well for the applications where corrosion is a factor.This type of finned tube is often used as an alternative to the more expensive extruded type fin in corrosive environments.

Fin tubes are a type of heat exchanger that is used in many different industries. These tubes have a finned surface, which increases their surface area and allows them to transfer heat more efficiently. This makes them ideal for applications where high heat transfer rates are required, such as in power plants and refrigeration systems.

Fin tubes are made from a variety of materials, including copper, aluminum, and stainless steel. They are available in a range of sizes and shapes and can be customized to meet the specific needs of each application.

One of the key benefits of fin tubes is their ability to operate efficiently at high temperatures and pressures. This makes them suitable for use in a wide range of applications, including air conditioning, heat exchangers, and radiators.

In addition to their high thermal performance, fin tubes are also durable and long-lasting. They are resistant to corrosion and can withstand the harsh environments often found in industrial settings. This makes them a cost-effective solution for many different industries.

The first actual inspection work on the fin tube heat exchanger is the raw materials inspection. Based on the ASME Code, providing material test reports for fin tube heat exchanger plates is mandatory. For other components, the marking inspection will be enough.

The Finned Tube is exposed to the outside to prevent rainwater from falling, try to keep it dry, and it should not be too close to the ground to prevent the irrigation in the greenhouse from corroding the finned tube. After the maintenance of the finned tube, the service life of the finned tube will be greatly increased.

We are a pretty proactive bunch. So, while we do charge a small fee per design to cover our costs, we absorb these costs when it is for a regular customer or where we are working jointly on a project. We also refund the fees in case it is followed by an order.

Absolutely, we can.

Applied Fin Tube is made with strip wrapped under tension around the base of the tube. Fins are welded to the base tube at the strip ends.

Pin Fin tubes are made from wire. Being cylindrical, wire has a larger area per unit of weight than the strip used in L type fin tubes. Also, due to the looped nature of the wire, less material is put on the tube than in the case of L fins. Consequently, the surface area of fins per meter of tubes is also less. However due to the superior turbulence created by the looped wire the actual heat transfer per meter of tube is significantly higher than in the case of L Type Fin Tubes. All of this together contributes to the weight differential between wire wound fin tubes and L Type Fin Tubes. In the case of similar metals, it is weighing half and in the case of Aluminium L fin vs. Steel wire fin they weigh about the same. The higher performance S5 pin fin tubes have an airside heat transfer performance per meter of tube that is 250% of the L type fin tubes.

Yes. A lot of our customer choose to supply their own pipes or tubes, however, a lot of customers ask us to supply them and we are happy to accommodate! We stock various sizes and if we don’t have what you need we can bring it in from one of our many suppliers. If you would like us to include the pipe or tube material in your order, please indicate that when you request a QUOTE.

A continuous helical fin is attached to the base tube by high frequency electric resistance welding in order to give an efficient and thermally reliable bond. Fins can be either solid or serrated (segmented). The weld produced in this process is a true forge, blacksmith weld. This type of weld is comprised of a fusion between two portions of parent metal without the introduction of a filler material. The weld is simply produced by heating the interfaces to be joined to a plastic state and applying pressure.

Used in boilers, furnaces and fired heaters for efficient heat recovery.

The main uses for high frequency welded finned tubes are in the heat recovery associated with boilers for power generation and in furnace applications for the petrochemical industry.

Our finning machines are equipped with online single or duplex cold bending equipment that can manipulate both ends of tubes in a single operation, thus ensuring exact alignment of the ends.

We do not. Our market lends itself to customer designed products, each special in itself. The number of combinations of diameter, overall length, materials and fin specs are too vast. Sunny Steel builds each finned product to each customers needs.

Finned tubes are the main components of heat exchangers. They are a series of tubes where fins have been added on the outside to increase the contact area with the outside fluid, to exchange heat and between the fluid inside the tube and the fluid outside the tube. Finned tubes are elongated aluminium cladded carbon steel flat tubes with brazed aluminium fins.

The rate at which such heat transfer can occur depends on three factors:

For any kind of information and request do not hesitate to contact our team, Sunny Steel is at your complete disposal.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.