Exceptional Corrosion Resistance

904l stainless steel bar delivers superior resistance to pitting, crevice corrosion, and acids in harsh environments, offering up to 50% longer service life than 316l grades while ensuring excellent weldability and formability for demanding industrial uses.

Exceptional Corrosion Resistance

904l stainless steel bar delivers superior resistance to pitting, crevice corrosion, and acids in harsh environments, offering up to 50% longer service life than 316l grades while ensuring excellent weldability and formability for demanding industrial uses.

Advanced UNS N08904 Super Austenitic Bars Engineered for Unmatched Durability in Acidic Chemical Processing and Marine Exposure

904L Stainless Steel Bar, designated as UNS N08904, is a premium low-carbon austenitic alloy optimized for severe corrosive conditions. Enriched with high levels of nickel, chromium, molybdenum, and copper, it provides robust defense against pitting, crevice corrosion, and stress cracking in environments involving chlorides, sulfuric acid, and seawater. This versatile bar stock is extensively applied in chemical reactors, offshore platforms, and desalination systems, where its non-magnetic nature, superior toughness, and ease of fabrication ensure prolonged reliability and reduced maintenance in high-stakes operations.

| Material Grade | UNS N08904 / 1.4539 / N08904 |

|---|---|

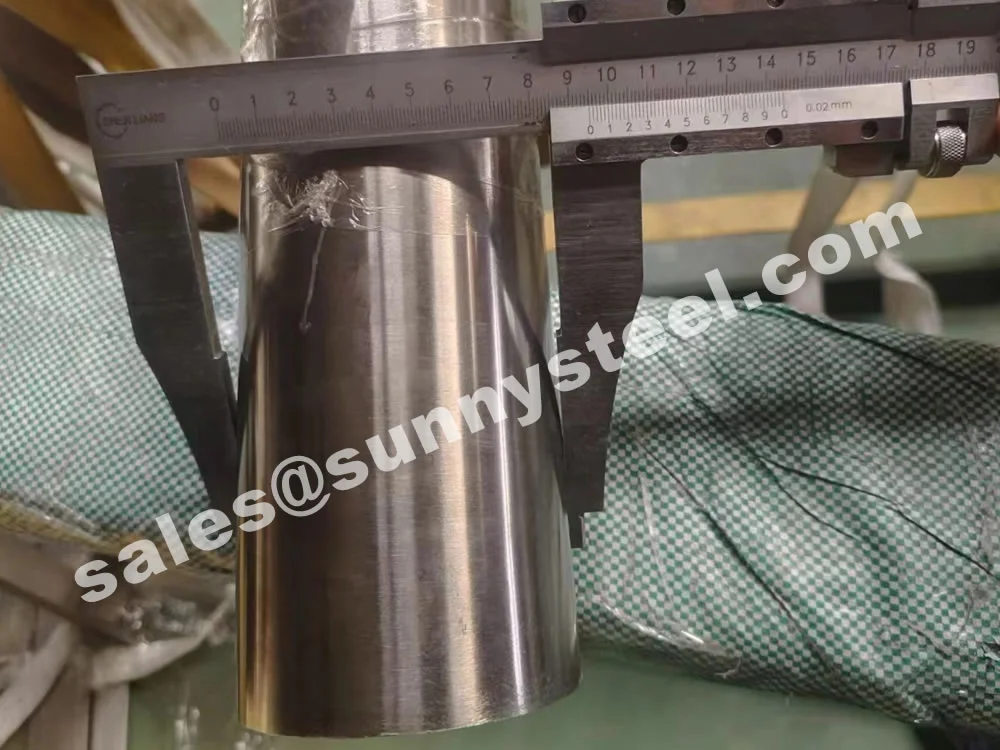

| Bar Diameter Range | 5 mm to 100 mm |

| Bar Length | Up to 6 m (custom lengths available) |

| Operating Temperature | -196°C to 400°C |

| Yield Strength (0.2% offset) | Min 220 MPa |

| Tensile Strength | 490–690 MPa |

| Elongation (50 mm gauge) | Min 35% |

| Chemical Composition (Key) | Cr: 19-23%, Ni: 23-28%, Mo: 4-5%, Cu: 1-2%, C: ≤0.02% |

Alloy 904 (N08904) stainless steel is a high alloy austenitic product intended for use under severely corrosive conditions. It delivers reliable performance against multiple corrosion types, making it suitable for harsh industrial environments.

Grade 904L stainless steel is a non-stabilized austenitic stainless steel with low carbon content. This high alloy variant incorporates copper to enhance resistance to strong reducing acids (such as sulphuric acid) while maintaining resistance to stress corrosion cracking and crevice corrosion. It is non-magnetic, offering excellent formability, toughness and weldability.

Notably, Grade 904L contains high amounts of expensive ingredients like molybdenum and nickel. Today, many applications previously using Grade 904L have been replaced by low-cost duplex stainless steel 2205.

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤0.020 |

| Chromium (Cr) | 19.0-23.0 |

| Nickel (Ni) | 23.0-28.0 |

| Molybdenum (Mo) | 4.0-5.0 |

| Copper (Cu) | 1.0-2.0 |

| Manganese (Mn) | ≤2.0 |

| Silicon (Si) | ≤1.0 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.035 |

| Nitrogen (N) | ≤0.10 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 490 |

| Yield Strength, min (MPa) | 220 |

| Elongation, min (%) | 35 |

| Hardness, max (HRB) | 90 |

| Feature | 904L (UNS N08904) | 316L (UNS S31603) | 304L (UNS S30403) | 254 SMO (UNS S31254) |

|---|---|---|---|---|

| Material Type | Austenitic Stainless | Austenitic Stainless | Austenitic Stainless | Super-Austenitic Stainless |

| Temperature Range | Up to 400°C | Up to 870°C | Up to 870°C | Up to 450°C |

| Notch Toughness | Excellent (High Ni) | Good | Good | Superior (High Mo/N) |

| Corrosion Resistance | Excellent (PREN >35, Cu/Mo) | Good (PREN 24) | Fair (PREN 18) | Outstanding (PREN 42) |

| Applications | Desalination, Acid Processing, FGD | Marine, Food, General Chemical | General Piping, Architectural | Seawater, Pulp Bleaching |

| Tensile Strength (MPa) | 490 (min) | 485 (min) | 485 (min) | 650 (min) |

| Yield Strength (MPa) | 220 (min) | 170 (min) | 170 (min) | 300 (min) |

| Key Advantage | Reducing acid/SCC resistance | Cost-effective chloride resistance | Versatile general use | Ultra-high pitting resistance |

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0