Heavy-duty Abrasion Solution

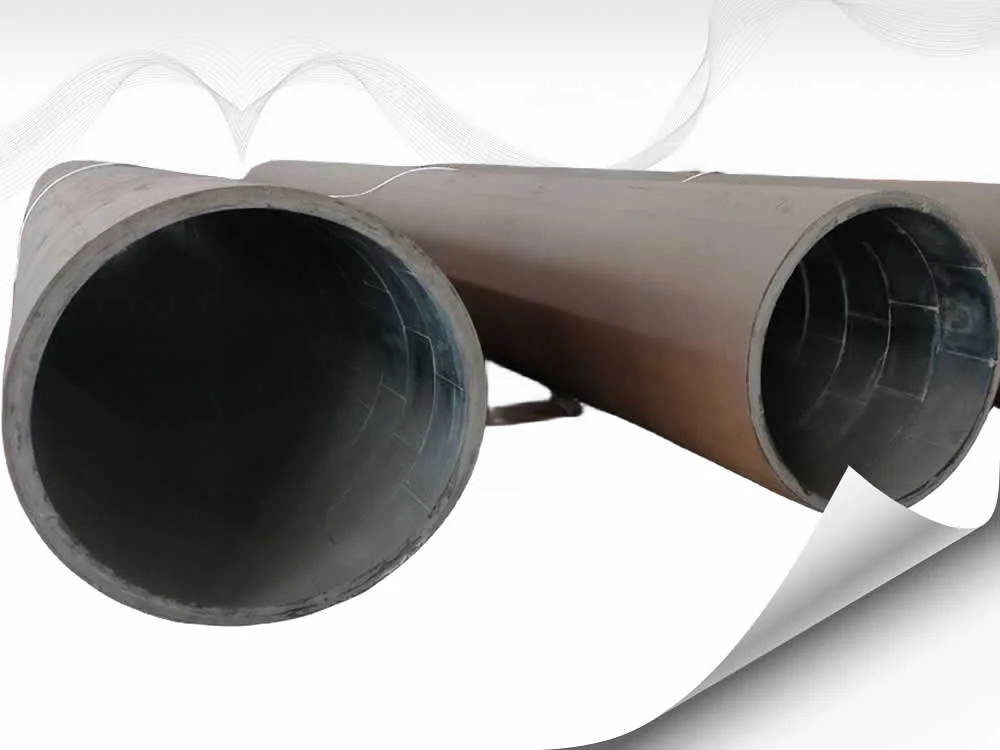

Cast basalt tile lined pipe offers excellent resistance to abrasion, corrosion, and high temperatures, making it ideal for slurry, ash, and bulk material systems.

Heavy-duty Abrasion Solution

Cast basalt tile lined pipe offers excellent resistance to abrasion, corrosion, and high temperatures, making it ideal for slurry, ash, and bulk material systems.

Interlocking cast basalt tiles inside steel pipes ensure outstanding resistance to wear, corrosion, and high temperatures in harsh industrial flows.

Cast basalt tile lined pipes are advanced composite piping systems designed to withstand the most abrasive and corrosive industrial environments. These pipes feature a robust carbon steel shell internally fitted with interlocking cast basalt tiles that form a smooth, wear-resistant lining. The basalt tiles, formed from naturally occurring volcanic rock, are cast at high temperatures (over 1300°C) and precisely cut for seamless fitting.

Exceptional Abrasion Resistance: With a Mohs hardness of 7–8, basalt tiles provide a long-lasting internal surface that resists aggressive wear from particles such as ash, slag, ore, and sand.

Chemical Corrosion Protection: Cast basalt is naturally resistant to acids, alkalis, and chemical fumes, ensuring pipe longevity even in chemically aggressive flows.

High-Temperature Stability: Suitable for continuous operation in environments up to 450°C, making it ideal for hot ash or exhaust dust transfer.

Smooth Internal Surface: The polished basalt lining minimizes flow resistance, reduces buildup, and promotes efficient transport of materials.

Modular & Flexible Design: Customizable for various pipe diameters (DN50 to DN800+), with options for flanged, welded, or socket connections.

Extended Service Life: Typically lasts 5–10 times longer than steel or rubber-lined alternatives in comparable service conditions.

Far exceeds unlined steel, AR plate and most ceramic linings in severe sliding abrasion.

Resists almost all acids, alkalis and saline solutions (except HF).

Continuous service up to 350–450 °C (grade dependent).

Prevents material adhesion and reduces pressure loss & energy consumption.

Steel outer shell allows normal welding. Damaged sections can be cut out and replaced individually without dismantling the entire line.

Cast basalt lined pipes (also known as玄武岩铸石衬里钢管) offer exceptional abrasion resistance, corrosion resistance, and smooth flow characteristics, making them ideal for hydraulic & pneumatic conveying of abrasive slurries in medium-impact environments.

Fly ash & bottom ash slurry lines,

FGD (flue gas desulfurization) pipelines,

coal dust pneumatic conveying,

ash sluiceways & hydraulic ash transport

Ore tailings slurry pipelines,

hydraulic fill lines,

concentrate & fine particle transport,

sand/gravel hydraulic conveying

Raw meal & clinker dust pneumatic lines,

limestone/quartz sand conveying,

separator cyclones discharge,

high-wear slurry transport

Sinter & coke breeze lines,

slag slurry pipelines,

dust collection ducts,

iron ore pellet transport

Dredge pump discharge pipelines,

sand & gravel slurry lines,

cutter suction dredger pipes,

reclamation fill transport

Phosphoric acid slurry lines,

fertilizer granulation dust conveying,

mildly corrosive abrasive slurries,

saltwater ash transport

Cast basalt lined pipes are custom-manufactured with standard steel outer shells and precision-fitted basalt cylinders (20–30 mm thick). They can be cut, welded, and flanged using conventional methods for easy on-site installation.

Steel-Lined Composite Cast Basalt Chute

Sort:0

Heavy Calibre Lining Tiles Composite Pipe

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0

Wear-Resistant Hardfacing Liner Plate

Sort:0