Tag#for Chromium Carbide Overlay Get: 10 results

Defend your boiler pipes and industrial pipelines with chromium carbide overlay wear plate, offering hrc58-62 hardness and up to 1100°f resistance to combat erosion, corrosion, and abrasion. this cost-effective cladding solution extends equipment life 5-10x, minimizes downtime in mining and power sectors, and ensures seamless integration for reliable, low-maintenance protection against harsh environments.

Hardfaced grinding rollers with chromium carbide overlay for vertical mills and crushers. hrc58-65 hardness, custom sizes. superior abrasion resistance for cement, mining, power, and steel industries.

High-performance cco plate with evenly distributed chromium carbide overlay on mild steel base. macro-hardness 57-63 hrc, excellent wear resistance per astm g65. uniform thickness, flat surface, multiple grades for mining, steel, cement, and power industries. custom fabrication available.

High-performance hardfacing steel plates with chromium carbide overlay for exceptional wear resistance, impact toughness, and heat/corrosion protection.

Hard weld lined steel pipes with chromium carbide overlay (hrc58-65 hardness) for extreme abrasion resistance. open arc or submerged arc welding.

Fortify your boiler systems with cco pipe corrosion protection, delivering hrc55-62 hardness and up to 800°c resistance to erosion and chemical attacks. this chromium carbide overlay pipe extends service life 4-5x in mining slurries and power plant ash lines, minimizing leaks and downtime while ensuring seamless weldability for easy retrofits.

Hard facing pipes feature welded chromium carbide overlay for extreme abrasion and erosion resistance—delivering up to 10-15x longer lifespan in high-wear slurry and powder transport.

Premium od-clad externally hardfaced abrasion resistant tubes with carbide-rich outer layer (>800 hv hardness).

Hardfacing elbows feature welded abrasion-resistant overlay (chromium carbide, tungsten carbide) on carbon steel bends for superior protection in high-wear zones.

Professional manufacturer of chromium carbide overlay (cco) wear plates – bimetallic hardfacing steel with 35% cr, 5.5% c for extreme abrasion resistance. hh-700b, hh-850a grades; thicknesses 3-12mm; custom sizes. ideal for mining, cement, power, steel mills – 20x longer life than mild steel.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

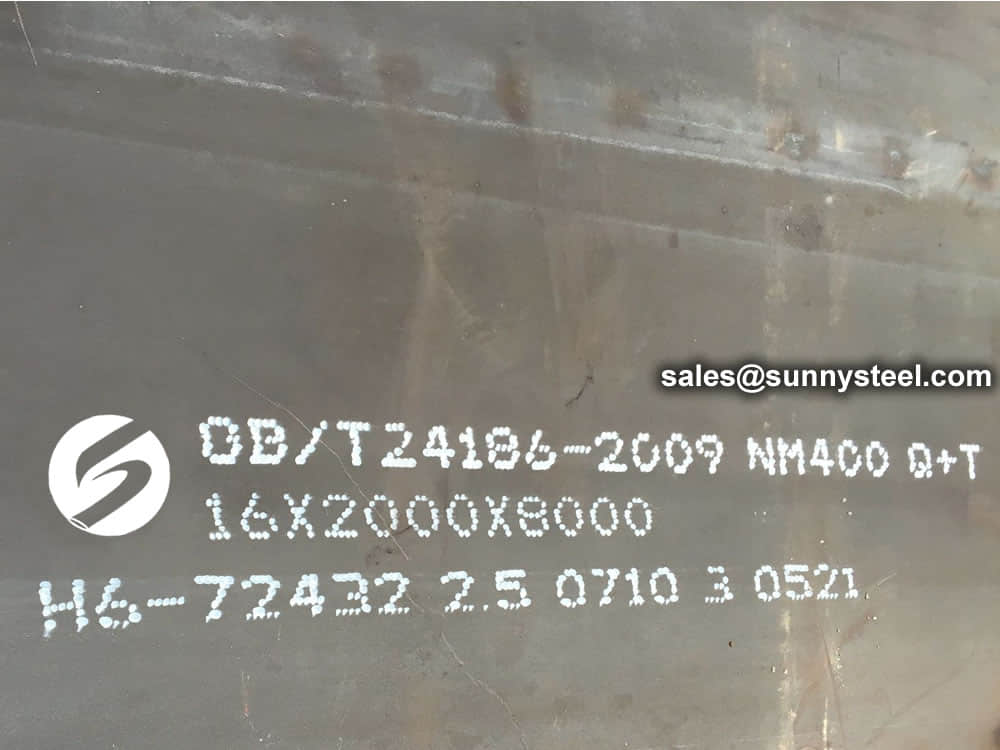

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.