Precision Seamless

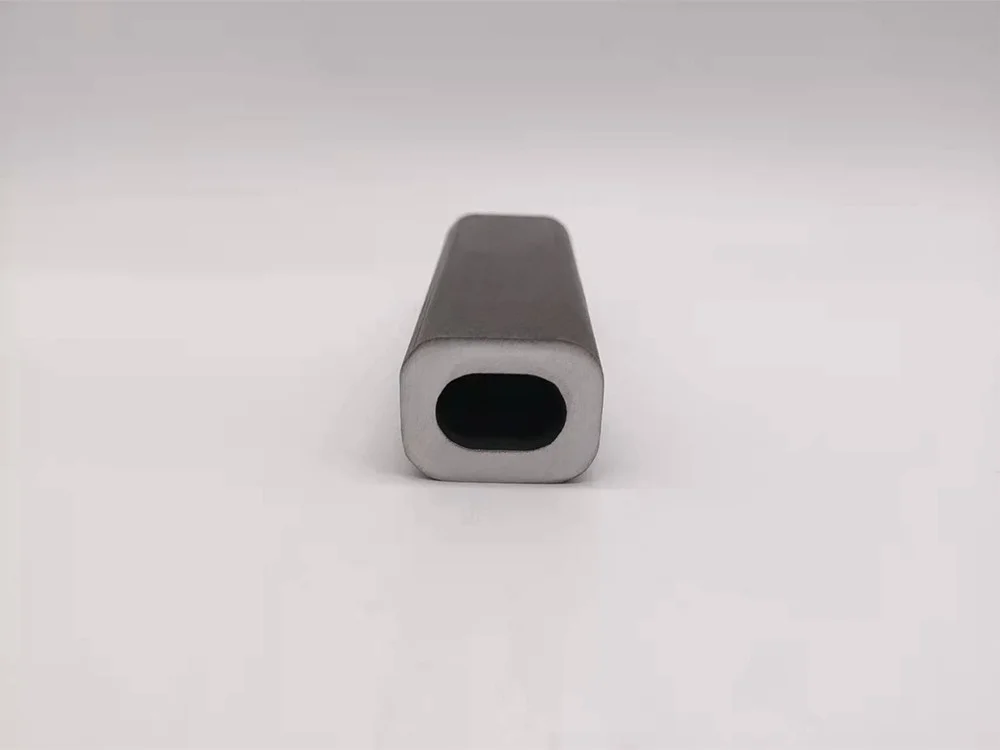

Special Shaped Alloy Steel Tubes are precision-engineered seamless tubes with non-circular cross-sections, designed to meet demanding industrial requirements where standard round tubes fall short.

Precision Seamless

Special Shaped Alloy Steel Tubes are precision-engineered seamless tubes with non-circular cross-sections, designed to meet demanding industrial requirements where standard round tubes fall short.

Precision-engineered seamless special shaped alloy steel tubes with custom cross-sections for demanding industrial applications. These tubes offer tailored material composition, mechanical properties, dimensional accuracy (±0.1mm tolerance), and complex geometries. Small-batch production is supported with full customization, value-added machining, and compliance to international standards (ASTM, EN, DIN, JIS, GOST). Produced via cold drawing and cold rolling for superior surface finish, uniformity, and performance.

Full customization of cross-section geometry; seamless construction; high precision for structural, load-bearing, and assembly applications.

| Parameter | Range | Notes |

|---|---|---|

| Outer Dimension (equivalent OD) | 10–108 mm (0.39"–4.25") | Fully customizable |

| Wall Thickness | 1–20 mm (0.039"–0.79") | ±0.1 mm precision tolerance; excellent uniformity |

| Length | Custom | Per customer requirement |

| Tolerance (ID/OD in select apps) | ±0.05 mm | e.g., construction machinery |

| Straightness | ≤0.5 mm/m | High precision applications |

Over 100 grades available; full customization of chemistry and properties (yield strength 350–1200 MPa possible).

Special Shaped Alloy Steel Tubes excel in diverse sectors:

ZG35Cr24Ni7SiN is a high-performance heat-resistant cast alloy engineered for extreme thermal environments. It offers exceptional durability, oxidation resistance, and cost efficiency—making it the smart choice for demanding high-temperature applications.

Designed for continuous operation up to 1050°C, ZG35Cr24Ni7SiN maintains structural stability and mechanical strength even under prolonged thermal exposure.

High chromium and silicon content form a dense, protective oxide layer that significantly reduces metal loss and extends maintenance intervals.

Nitrogen alloying dramatically improves creep resistance and high-temperature strength, outperforming conventional Cr–Ni cast steels during long-term service.

Delivers performance comparable to high-Ni grades like ZG40Cr25Ni20 in many applications—at a significantly lower alloy cost.

Superior castability enables production of large, intricate one-piece components—reducing welds, joints, and potential failure points.

Selecting the right wear material is critical for service life and operating cost. Below is a practical comparison of common wear-resistant materials.

| Material | Typical Hardness | Wear Resistance | Impact Resistance | Service Temperature | Cost Level | Typical Applications |

|---|---|---|---|---|---|---|

| KmTBCr26 | HRC 58–65 | ★★★★★ | ★★ | ≤ 500°C | ★★★ | Severe abrasion liners, chutes, wear plates, mining & cement equipment |

| Ni-Hard (Ni-Hard 4) | HRC 55–60 | ★★★★ | ★★★ | ≤ 400°C | ★★★ | Impact + abrasion parts, mill liners, crusher components |

| Cr20 Cast Iron | HRC 50–58 | ★★★☆ | ★★☆ | ≤ 450°C | ★★ | Medium abrasion conditions, general wear parts |

| Hardfacing Overlay | HRC 55–62 | ★★★★☆ | ★★★ | ≤ 600°C* | ★★★★ | Local wear protection, repair and reinforcement |

Sort:0

ASTM A519 Carbon and Alloy Steel Mechanical Tubing

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99

Sort:0