Alloy Steel Pipe For High-temperature And High-pressure Applications

Astm a335 p5 alloy steel pipes offer superior high-temperature strength, creep resistance, and corrosion protection—ideal for power plants, refineries, and industrial piping systems.

Alloy Steel Pipe For High-temperature And High-pressure Applications

Astm a335 p5 alloy steel pipes offer superior high-temperature strength, creep resistance, and corrosion protection—ideal for power plants, refineries, and industrial piping systems.

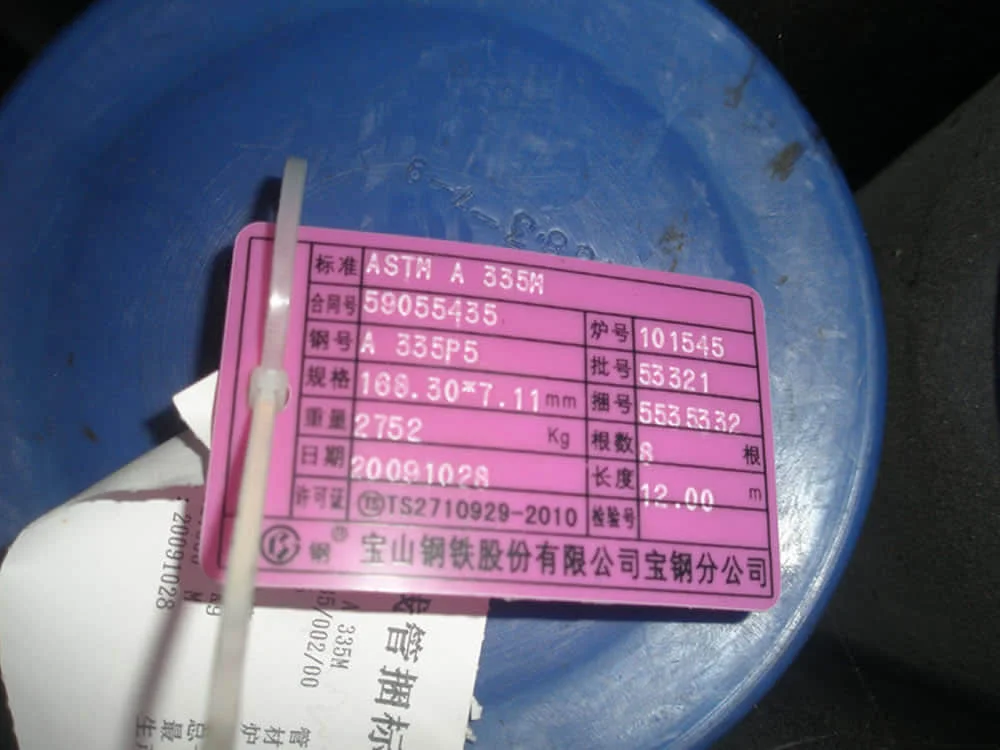

ASTM A335 P5 Pipe is a seamless ferritic alloy steel pipe designed for high-temperature service in critical industrial systems. It conforms to ASTM A335/ASME SA335 specifications and is widely used in power generation, refineries, and petrochemical plants where both strength and corrosion resistance are essential.

The P5 grade contains 4.00–6.00% chromium and 0.45–0.65% molybdenum, delivering excellent resistance to oxidation, thermal fatigue, and chemical attack. This Chrome Moly Pipe is commonly used in boiler tubes, heat exchangers, and steam piping systems, where durability and elevated temperature performance are required.

The ASTM A335 P5 seamless pipe is available in cold-drawn or hot-finished conditions with optional heat treatment (annealed, normalized, tempered). Its seamless construction enhances structural integrity, making it a reliable choice under cyclic loading and thermal expansion conditions.

These pipes are available in outer diameters from 1/2” to 24” (DN15–DN600), with wall thickness from SCH 20 to XXH. Ends can be plain, beveled, or threaded as required. Surface treatments like varnishing, FBE, or 3LPE coatings are also available to improve corrosion resistance in harsh service environments.

With superior weldability and dimensional accuracy, P5 alloy steel pipe supports efficient fabrication and installation. Preheating and post-weld heat treatment (PWHT) are recommended to prevent cracking and ensure long-term operational safety.

| Feature | ASTM A335 P5 | ASTM A335 P9 | ASTM A519 4140 |

|---|---|---|---|

| Material Type | Alloy Steel | Alloy Steel | Alloy Steel |

| Chromium Content | 4.00-6.00% | 8.00-10.00% | 0.80-1.10% |

| Molybdenum Content | 0.45-0.65% | 0.90-1.10% | 0.15-0.25% |

| Temperature Range | High (up to 650°C) | High (up to 750°C) | Moderate to High |

| Corrosion Resistance | Good (With coatings) | Excellent (With coatings) | Good (With coatings) |

| Applications | Boilers, Refineries | Petrochemical, Power Plants | Gears, Shafts, Hydraulics |

| Tensile Strength (MPa) | 415 (min) | 415 (min) | 655-862 |

| Yield Strength (MPa) | 205 (min) | 205 (min) | 415-690 |

| Key Advantage | Balanced high-temp strength | Superior corrosion resistance | High strength and hardness |

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤0.15 |

| Manganese (Mn) | 0.30-0.60 |

| Phosphorus (P) | ≤0.025 |

| Sulfur (S) | ≤0.025 |

| Silicon (Si) | ≤0.50 |

| Chromium (Cr) | 4.00-6.00 |

| Molybdenum (Mo) | 0.45-0.65 |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 415 |

| Yield Strength, min (MPa) | 205 |

| Elongation, min (%) | 30 |

| Hardness, max (HBW) | 163 |

Withstands temperatures up to 650°C for boilers and refineries.

High chromium content ensures resistance to oxidation and corrosion.

Molybdenum enhances durability in high-pressure systems.

Uniform construction ensures reliability in high-pressure applications.

Long lifespan reduces maintenance and replacement costs.

Ideal for boilers, refineries, and petrochemical systems.

Below is a detailed list of available pipe specifications, including outer diameter (O.D), wall thickness (W.T), length, and quantity.

| Spec. | Grade | O.D mm |

W.T mm |

Length mm |

Qty pcs |

|---|---|---|---|---|---|

| ASTM A335 | P5 | 25 | 3 | 12000 | 12 |

| ASTM A335 | P5 | 32 | 3 | 16 | |

| GB9948 | 1Cr5Mo | 48 | 5 | 8200 | 11 |

| ASTM A335 | P5 | 48.3 | 5.08 | 6000-12000 | 83 |

| MAL 037 | 1Cr5Mo | 60.3 | 5 | 6000-12000 | 48 |

| ASTM A335 | P5 | 60.3 | 5.6 | 3 | |

| MAL 037 | 1Cr5Mo | 76 | 6 | 6000-12000 | 2 |

| GB9948 | 1Cr5Mo | 89 | 8 | 10000 | 9 |

| ASTM A335 | P5 | 101.6 | 5.74 | 10400 | 5 |

| ASTM A335 | P5 | 101.6 | 5.74 | 6000-12000 | 4 |

| ASTM A335 | P5 | 102 | 8 | 6000-12000 | 3 |

| ASTM A335 | P5 | 114.3 | 6 | 11800 | 12 |

| ASTM A335 | P5 | 114.3 | 6 | 6000-12000 | 5 |

| GB9948 | 1Cr5Mo | 114 | 7 | 6000-12000 | 9 |

| GB9948 | 1Cr5Mo | 114 | 8 | 8000 | 16 |

| GB9948 | 1Cr5Mo | 114.3 | 8.56 | 6000-12000 | 42 |

| ASTM A335 | P5 | 152 | 6.5 | 11000 | 4 |

| ASTM A335 | P5 | 152 | 6.5 | 6000-12000 | 2 |

| GB9948 | 1Cr5Mo | 152 | 8 | 6000-12000 | 5 |

| JIS G3467 | STFA25 | 152.4 | 10 | 12000 | 53 |

| ASTM A335 | P5 | 159 | 8 | 2 | |

| ASTM A335 | P5 | 159 | 8 | ||

| GB9948 | 1CR5MO | 168 | 6 | 6000-12000 | 13 |

| ASTM A335 | P5 | 168 | 7 | 6000-12000 | 13 |

| ASTM A335 | P5 | 168.3 | 7.11 | 12000 | 44 |

| ASTM A335 | P5 | 168.3 | 7.11 | 6000-12000 | 7 |

| ASTM A335 | P5 | 168.3 | 7.11 | 28/259.85,20/166.28 | 58 |

| ASTM A335 | P5 | 168.3 | 7.11 | 12000 | 57 |

| GB9948 | 1CR5MO | 168 | 9.5 | 28 | |

| ASTM A335 | P5 | 168.3 | 10.97 | ||

| ASTM A335 | P5 | 168.3 | 14.27 | 37 | |

| ASTM A335 | P5 | 168.3 | 16 | 22 | |

| ASTM A335 | P5 | 168.3 | 24 | 5000 | 2 |

| ASTM A335 | P5 | 219.1 | 8 | ||

| ASTM A335 | P5 | 219.1 | 8.18 | 6000 | 24 |

| ASTM A335 | P5 | 219.1 | 8.18 | 12000 | 37 |

| ASTM A335 | P5 | 219.1 | 10 | 9600 | 35 |

| GB9948 | 1CR5MO | 219 | 10 | 24 | |

| ASTM A335 | P5 | 219.1 | 12 | 10 | |

| ASTM A335 | P5 | 219.1 | 14 | ||

| ASTM A335 | P5 | 219.1 | 16 | ||

| ASTM A335 | P5 | 219.1 | 18 | ||

| ASTM A335 | P5 | 219.1 | 20 | 11 | |

| ASTM A335 | P5 | 219.1 | 24 | ||

| ASTM A335 | P5 | 273 | 9 | 3 | |

| ASTM A335 | P5 | 273.1 | 9.27 | 14 | |

| ASTM A335 | P5 | 273.1 | 10 | 15 | |

| ASTM A335 | P5 | 273.1 | 15.09 | 9 | |

| GB9948 | 1CR5MO | 273 | 18 | 2 | |

| ASTM A335 | P5 | 323.9 | 10.31 | 12000 | 10 |

| ASTM A335 | P5 | 325 | 12 | 2 | |

| ASTM A335 | P5 | 355.6 | 27.79 | 8000 | 4 |

| ASTM A335 | P5 | 377 | 15 | 1 | |

| ASTM A335 | P5 | 377 | 16 | 11 | |

| ASTM A335 | P5 | 406 | 14 | 3 | |

| ASTM A335 | P5 | 406.4 | 26.19 | 7000 | 5 |

| ASTM A335 | P5 | 406.4 | 30.96 | 6000 | 6 |

| ASTM A335 | P5 | 473 | 14 | 2 | |

| ASTM A335 | P5 | 609.6 | 16 | 1 | |

| ASTM A335 | P5 | 914 | 32 | 1 |

| Element | C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| Content | ≤ 0.15 | ≤ 0.50 | ≤ 0.60 | ≤ 0.035 | ≤ 0.030 | 4.00 – 6.00 | 0.45 – 0.60 | ≤ 0.60 |

| Property | Value |

|---|---|

| Yield Strength, min (MPa) | 390 |

| Tensile Strength, min (MPa) | 590 |

| Elongation, min (%) | 18 |

| Alternative Range (MPa) | σy ≈ 411 MPa, σb = 579–716 MPa, Elongation = 13–72% |

| Property | Value |

|---|---|

| Density | ~7.93 g/cm³ |

| Thermal Conductivity | ~67 – 73 W/m·K |

| Specific Heat | ~450 J/kg·K |

| Electrical Resistivity | ~0.50 – 0.60 µΩ·m |

| Thermal Expansion Coefficient | ~13 × 10−6/K (20–100 °C) |

| Melting Point | ~1400 – 1500 °C |

Sort:0

ASTM A333 Grade 6 Pipe in stock

Sort:0

Sort:0

Sort:0

Sort:0

15NiCuMoNb5-6-4 Alloy Steel Pipe

Sort:0