High-strength Seamless Pipe For Boiler Systems

15nicumonb5-6-4 seamless alloy steel pipe offers superior corrosion resistance and high-temperature strength for boiler and power plant pipelines up to 500°c.

High-strength Seamless Pipe For Boiler Systems

15nicumonb5-6-4 seamless alloy steel pipe offers superior corrosion resistance and high-temperature strength for boiler and power plant pipelines up to 500°c.

15NiCuMoNb5-6-4, also known as WB36, is a bainitic Ni-Cu-Mo steel micro-alloyed with niobium, developed for pipeline corrosion protection and boiler pipeline steel applications. Conforming to EN 10216-2, ASTM A213 T36, and ASTM A335 P36 standards, it is ideal for high-pressure, high-temperature environments up to 500°C in power plants, petrochemical industries, and nuclear facilities.

The alloy’s composition, including nickel (1.00-1.30%), copper (0.50-0.80%), molybdenum (0.25-0.50%), and niobium (0.015-0.045%), enhances its high-temperature steel properties, such as creep resistance and oxidation resistance. It is used in boiler drums, steam separators, headers, steam generators, and steam pipelines, ensuring reliability in industrial piping solutions.

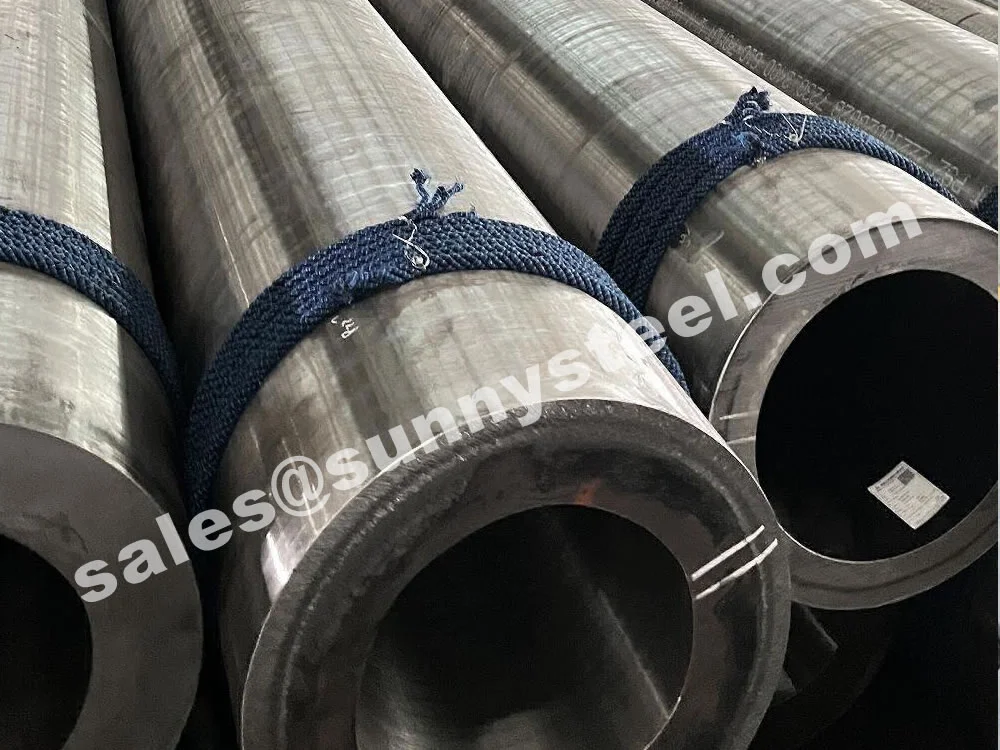

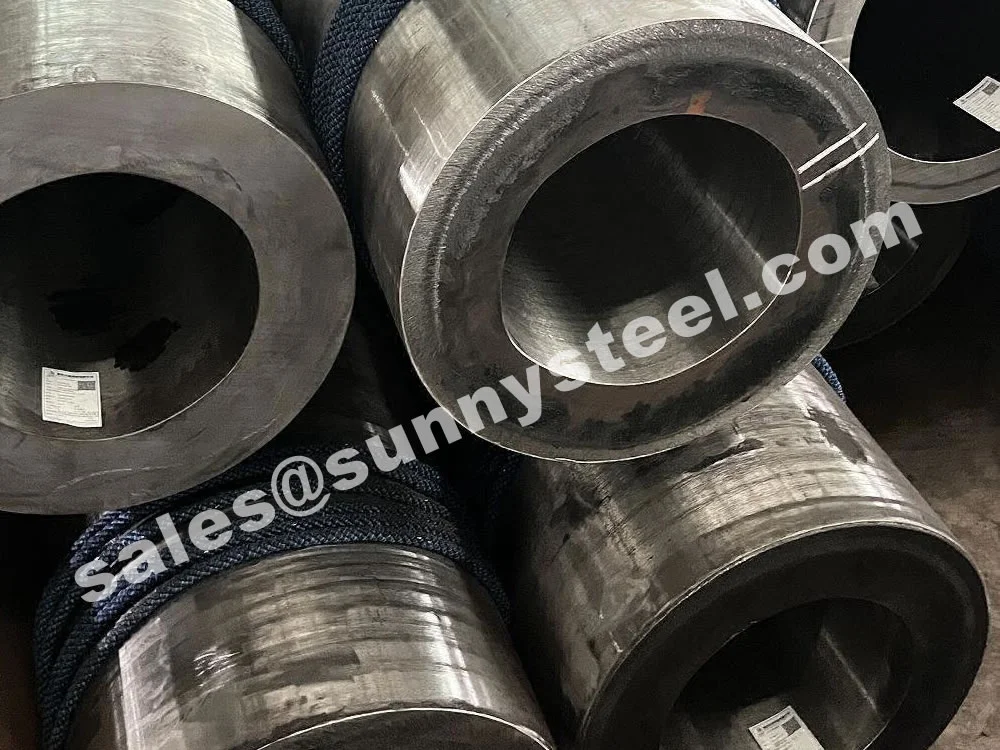

Manufactured via hot-rolled or cold-drawn processes, 15NiCuMoNb5-6-4 undergoes normalizing and tempering to achieve a bainite + ferrite + sorbite microstructure. It undergoes rigorous testing, including ultrasonic, hydrostatic, and flattening tests, to meet standards. Welding requires preheating (150-200°C) and post-weld heat treatment (590-610°C) to ensure weld integrity. Available in sizes from 10.2-711mm OD and 1.6-100 karmel wall thickness, with lengths up to 16,000mm, it supports customization and U-bending.

Compared to ASTM A335 P9 and P11, 15NiCuMoNb5-6-4 offers a cost-effective balance of strength and corrosion resistance, making it ideal for high-pressure boiler systems. Its equivalents, such as 15Ni1MnMoNbCu (China), provide flexibility, but substitution requires evaluation. This high-temperature steel ensures safety and longevity in demanding environments.

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.03 – 0.08 |

| Nickel (Ni) | 5.0 – 6.5 |

| Copper (Cu) | 4.5 – 6.0 |

| Molybdenum (Mo) | 0.8 – 1.2 |

| Niobium (Nb) | 0.05 – 0.10 |

| Manganese (Mn) | 0.30 – 0.70 |

| Silicon (Si) | ≤ 0.35 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.015 |

| Property | Value |

|---|---|

| Yield Strength | ≥ 275 MPa |

| Tensile Strength | 450 – 600 MPa |

| Elongation | ≥ 25 % |

| Impact (Charpy V‑Notch) | ≥ 34 J @ –196 °C |

| Country | Standard | Equivalent Grade |

|---|---|---|

| Germany | DIN EN 10216-4 | 15NiCuMoNb5-6-4 |

| France | NF A 36-205 | 15D3 (with NiCuMoNb) |

| USA | ASME SA/ASTM A333 Grade 8 / Grade 3 (partial) | Low Temp Nickel Steel |

| Russia | GOST | 09MnNiCuMoNb |

| China | GB/T | 15NiCuMoNb5 (相近成分) |

| Condition | Code | Description |

|---|---|---|

| Normalized | N | Heat treated above critical temperature and air cooled |

| Quenched and Tempered | QT | Heat treated and tempered for improved strength and toughness |

| Annealed | A | Softened for improved machinability and ductility |

| Process | Preheating Temp | Interpass Temp | Post-weld Heat Treatment (PWHT) |

|---|---|---|---|

| GTAW / TIG | 150 – 200°C | ≤ 250°C | 620 – 700°C / 1 – 2 hrs |

| SMAW / Stick | 160 – 200°C | ≤ 250°C | Required for wall >12 mm |

Alloy steel pipes are categorized by both standards and grades, each designed for specific performance requirements and applications. Common standards include ASTM A335, A519, and A213, while grades like P5, P9, P11, P22, and P91 are frequently used within these standards.

| Standard | Detailed Grades | Main Applications |

|---|---|---|

| ASTM A335 / ASME SA335 | P1, P2, P5, P9, P11, P12, P15, P21, P22, P23, P24, P36, P91, P92, P122, P911 | High-temperature pressure systems: power plants, refineries, and chemical plants |

| ASTM A213 / ASME SA213 | T2, T5, T5b, T9, T11, T12, T17, T22, T23, T24, T91, T92, T122, T911 | Boiler tubes, superheaters, and heat exchangers |

| ASTM A519 | 4130, 4135, 4140, 4145, 4150, 1020, 1026, 1330, 8620 | Mechanical tubing, structural applications, automotive components |

| API 5L | A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80, X100 | Oil and gas transmission pipelines (onshore and offshore) |

| EN 10216‑2 | 13CrMo4-5, 10CrMo9-10, 12CrMo19-5, X10CrMoVNb9-1, X11CrMo5, 14MoV6-3, X20CrMoV12-1 | European pressure vessels and high-temperature piping |

| GB / SH Standards | 15CrMoG, 12Cr1MoVG, 10CrMo910, 12CrMo, 1Cr5Mo, WB36, 10Cr9Mo1VNb (equiv. T91) | Petrochemical, power generation, high-pressure boilers in Chinese systems |

Alloy steel is made by combining carbon steel with one or several alloying elements, such as titanium, copper, chromium, aluminum, manganese, silicon, and nickel. This produces specific properties that are not found in standard carbon steel. Common alloy steel grades include 4130, 4140, 4340, and 8620 for their balance of characteristics like strength, toughness, machinability, and weldability.

Alloy steel pipes offer superior strength, temperature and corrosion resistance, making them ideal for demanding environments across energy, petrochemical, construction, and more.

Used extensively in drilling, subsea and onshore pipelines for crude oil, natural gas, and refined products due to high strength and corrosion resistance.

Ideal for transporting corrosive chemicals, high-pressure reactor feeds, and heat exchanger tubing where carbon steel fails.

Used in high-temp boiler tubes, superheaters, reheaters, and steam piping; withstands extreme temperatures and pressures efficiently.

Used as structural pipelines, piling tubes, and transport lines in high-rise buildings and bridges due to high structural strength.

Suitable for transporting liquefied gases and cold media, where toughness and strength must endure sub-zero temperatures.

Alloy steel pipes are fully recyclable and support energy-efficient systems, aligning with green standards in modern industry.

Sort:0

ASTM A333 Grade 6 Pipe in stock

Sort:0

Sort:0

Sort:0

Sort:0

Sort:0