Air-to-liquid Heat Transfer & Industrial Heat Recovery Solutions

High-efficiency finned tube heat exchangers (rippenrohr-wärmetauscher) for air-to-liquid heat transfer and industrial heat recovery.

Air-to-liquid Heat Transfer & Industrial Heat Recovery Solutions

High-efficiency finned tube heat exchangers (rippenrohr-wärmetauscher) for air-to-liquid heat transfer and industrial heat recovery.

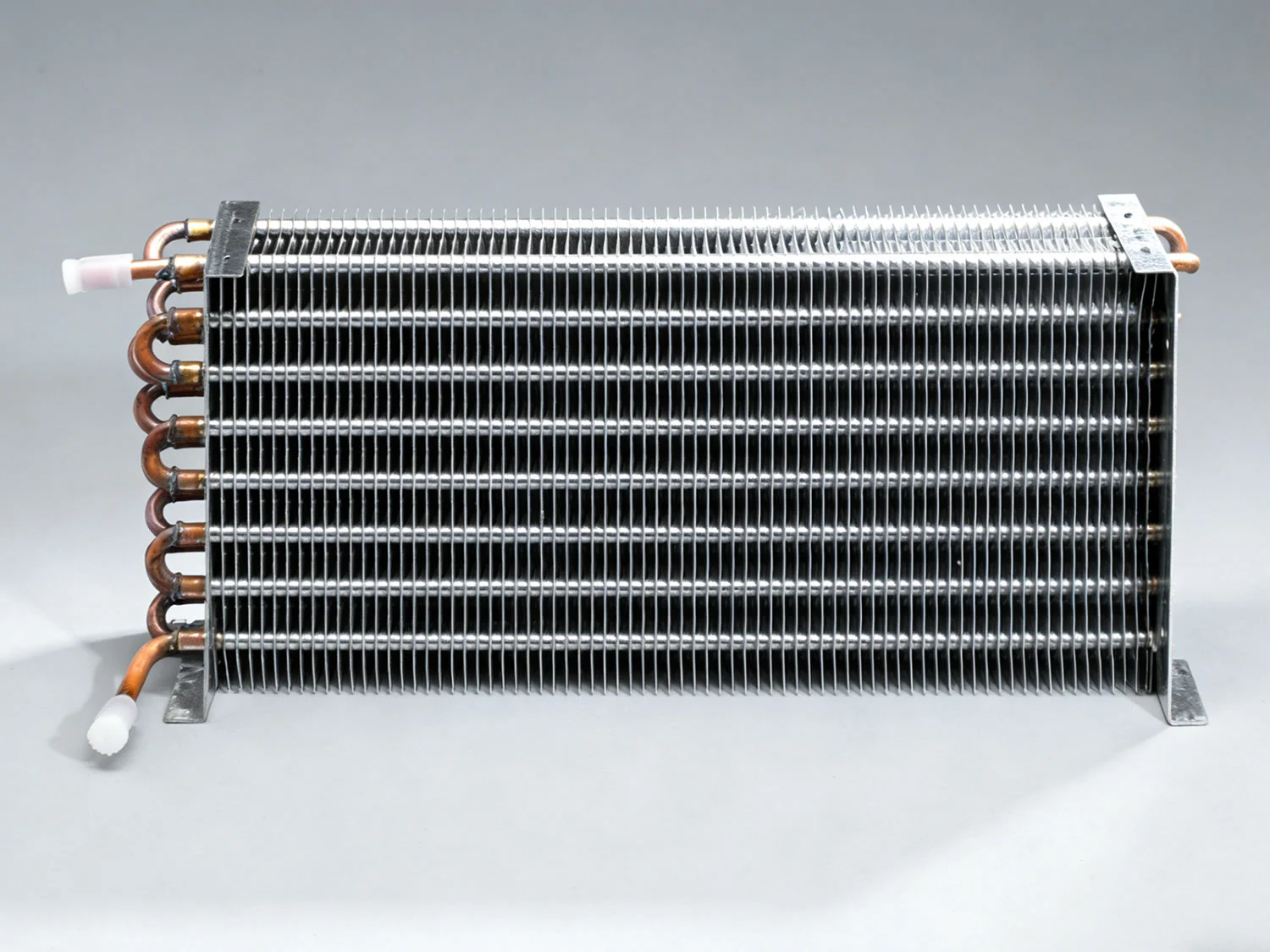

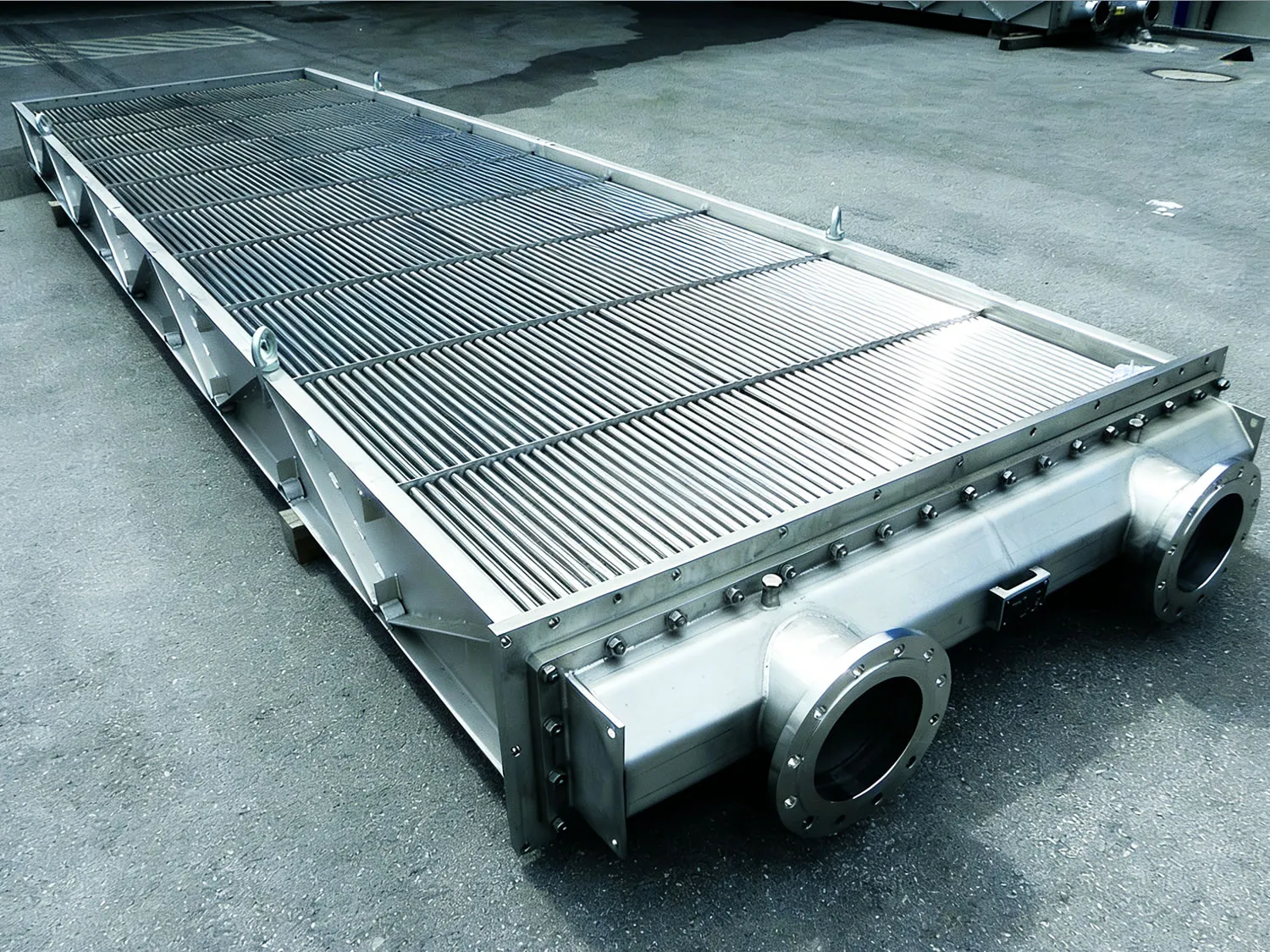

Finned tube heat exchangers (also called Rippenrohr-Wärmetauscher) transfer heat between a gaseous medium (air, exhaust gases) and a liquid (water, glycol). Fins attached to the tubes increase the external surface area, significantly boosting efficiency on the gas side where heat transfer coefficients are naturally low.

Common roles: Air heaters • Air coolers • Condensers • Exhaust heat recovery (economizers, preheaters, recuperators)

Mechanically pressed fins allow combination of different tube/fin materials. Fin parameters (height, thickness, spacing) tailored per application for optimal surface area, efficiency, and fouling resistance.

Finned tube radiators are highly efficient heat exchange devices that significantly increase the heat transfer area by adding fins to the base tube. This design enhances heat dissipation and transfer performance in a compact form.

They are widely used across industries such as textiles, printing & dyeing, petroleum, chemical processing, drying equipment, power generation, air conditioning, HVAC systems, metallurgy, and more. Suitable for both gas and liquid heat exchange applications, including air preheaters, condensers, and evaporators.

Key Benefits: Maximizes heat dissipation area, excellent corrosion and pressure resistance, compact structure with large unit heat exchange area, silent operation, energy-saving and environmentally friendly, easy installation and maintenance.

Increases surface area dramatically, enabling high heat dissipation in smaller volumes.

More heat exchange capacity in limited space; ideal for constrained installations.

Resistant to high temperatures, corrosion, and harsh environments; long service life.

Operates effectively in both low and high temperature conditions.

Simple cleaning and upkeep, especially in dusty or polluted environments.

Noiseless design, energy-efficient, and environmentally friendly.

Fins can be customized in various forms to meet specific application needs:

Base Tube Materials: Typically corrosion-resistant options such as stainless steel, copper, or aluminum alloy.

Mechanical pressing enables combination of stainless steel, copper, aluminum and other materials.

Adjustable fin height, thickness and pitch tailored to your specific application requirements.

Ideal for process technology, food industry, air conditioning and many other industrial sectors.

Based on your application requirements, customer specifications, or our expert consulting recommendations, we process a range of high-quality materials for finned tube coils and heat exchangers:

Ideal for excellent thermal conductivity and corrosion resistance

Enhanced durability for marine and corrosive environments

Lightweight with superior heat transfer properties

High strength and corrosion resistance for harsh applications

Our finned tube heat exchangers are engineered for superior thermal performance, versatile applications, and precision manufacturing—delivering efficient heat transfer solutions for diverse industrial needs.

Also known as air/water or gas/water heat exchangers, these systems facilitate efficient heat transfer between gaseous (e.g., air) and liquid (e.g., water) media. High thermal conductivity fins on tubes enhance heat transfer from gas to liquid, with applications including exhaust heat recovery, air heaters, coolers, and condensers.

Finned tube heat exchangers excel in heat recovery applications, efficiently capturing energy from warm/hot exhaust air/gases that would otherwise be wasted. Also referred to as economizers, preheaters, or recuperators, they enable cost-effective heat recuperation and sustainability across industrial processes.

After selecting the optimal heat exchanger type, we perform technical dimensioning using certified software and create 3D CAD models—optimized for efficiency, cost-effectiveness, and pressure loss. Production is executed on modern computer-aided systems, based on customer-approved CAD drawings for maximum accuracy.

Finned tube heat exchanger

Our finned tube heat exchangers serve a diverse range of industries and applications, delivering efficient thermal solutions tailored to your operational needs.

Sort:0

Sort:0

Customized Bend Extruded Fin Tube

Sort:0

Sort:0