Abrasion Resistant Pipe – Easy Installation & Maintenance

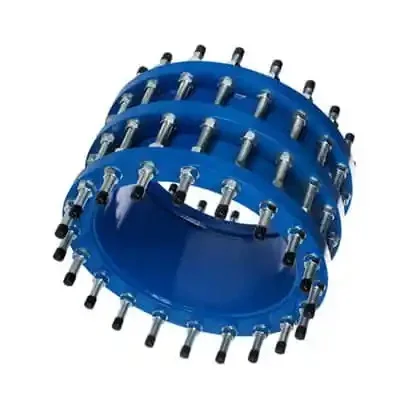

Dismantling joints for easy installation and removal of valves, pumps, and fittings.

Abrasion Resistant Pipe – Easy Installation & Maintenance

Dismantling joints for easy installation and removal of valves, pumps, and fittings. carbon steel with epoxy coating, sizes dn50-dn2000, pn10/16. axial adjustment, vibration absorption, ideal for water, wastewater, and industrial pipelines.

Dismantling joints are telescopic devices installed between flanged equipment and pipes to facilitate easy installation, removal, and maintenance without disturbing the pipeline. They absorb axial forces, allow length adjustment, and compensate for misalignment.

Essential for pump stations, valve chambers, and systems requiring frequent equipment access. Also known as expansion/dismantling fittings.

| Parameter | Specification |

|---|---|

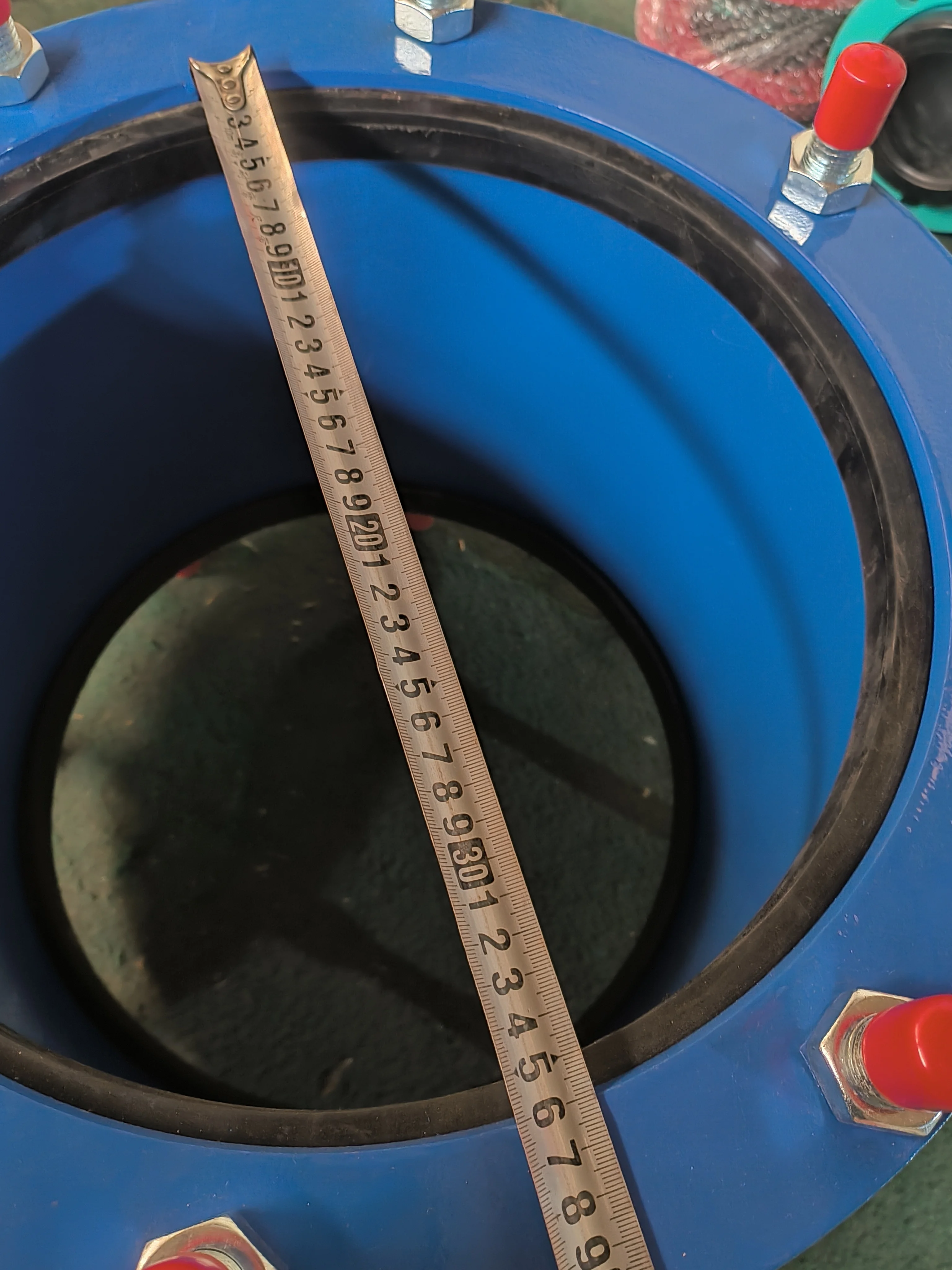

| Size Range | DN50–DN2000 (2"–80") |

| Pressure Rating | PN10 / PN16 / PN25 |

| Material | Carbon Steel (Q235B); Epoxy Coated |

| Flange Standard | EN1092-2, BS4504, ANSI B16.5 |

| Axial Adjustment | ±50 mm (standard; larger available) |

| Gasket | EPDM or NBR |

| Tie Rods | Galvanized Carbon Steel |

| Coating | Fusion Bonded Epoxy (250-300 μm) |

| Temperature | -10°C to +80°C |

Custom designs for higher pressure or special materials available.

| No. | Name | Quantity | Material |

|---|---|---|---|

| 1 | Body | 1 | QT450-10, Q235A |

| 2 | Gasket | 1 | NBR |

| 3 | Follover | 1 | QT450-10, Q235A |

| 4 | Limited short pipe | 1 | Q235A |

| 5 | bolt | 5 | Q235A, 35# |

| 6 | nut | 5 | Q235A, 2# |

Main data of dismantling joint

| Nominal Diameter DN | External diameter of pipe Dw | Length | Flange connecting dimension | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.6Mpa | 1.0Mpa | ||||||||||

| L | L1 | D | D1 | n-Th | b | D | D1 | n-Th | b | ||

| 65 | 76 | 200 | 40 | 160 | 130 | 4-M12 | 16 | 185 | 145 | 4-M16 | 20 |

| 80 | 89 | 190 | 150 | 4-M16 | 18 | 200 | 160 | 8-M16 | 22 | ||

| 100 | 114 | 210 | 170 | 220 | 180 | 24 | |||||

| 125 | 140 | 240 | 200 | 8-M16 | 20 | 250 | 210 | 26 | |||

| 150 | 168 | 265 | 225 | 285 | 240 | 8-M20 | |||||

| 200 | 219 | 320 | 280 | 22 | 340 | 295 | 28 | ||||

| 250 | 273 | 375 | 335 | 12-M16 | 24 | 395 | 350 | 12-M20 | |||

| 300 | 325 | 220 | 50 | 440 | 395 | 12-M20 | 24 | 445 | 400 | ||

| 350 | 377 | 490 | 445 | 26 | 505 | 460 | 16-M20 | 30 | |||

| 400 | 426 | 540 | 495 | 16-M20 | 28 | 565 | 515 | 16-M24 | 32 | ||

| 450 | 480 | 595 | 550 | 28 | 615 | 565 | 20-M24 | ||||

| 500 | 530 | 645 | 600 | 20-M20 | 30 | 670 | 620 | 34 | |||

| 600 | 630 | 240 | 755 | 705 | 20-M24 | 30 | 780 | 725 | 20-M27 | 36 | |

| 700 | 720 | 860 | 810 | 24-M24 | 32 | 895 | 840 | 24-M27 | 40 | ||

| 800 | 820 | 350 | 60 | 975 | 920 | 24-M27 | 34 | 1015 | 950 | 24-M30 | 44 |

| 900 | 920 | 1075 | 1020 | 36 | 1115 | 1050 | 28-M30 | 46 | |||

| 1000 | 1020 | 1175 | 1120 | 28-M27 | 1230 | 1160 | 28-M33 | 50 | |||

| 1200 | 1220 | 370 | 1405 | 1340 | 32-M30 | 40 | 1455 | 1380 | 32-M36 | 56 | |

| 1400 | 1420 | 1630 | 1560 | 36-M33 | 44 | 1675 | 1590 | 36-M39 | 62 | ||

| 1600 | 1620 | 380 | 1830 | 1760 | 40-M33 | 48 | 1915 | 1820 | 40-M45 | 68 | |

| 1800 | 1820 | 2045 | 1970 | 44-M36 | 50 | 2115 | 2020 | 44-M45 | 70 | ||

| 2000 | 2020 | 400 | 2265 | 2180 | 48-M39 | 54 | 2325 | 2230 | 48-M45 | 74 | |

| 2200 | 2220 | 2475 | 2390 | 52-M39 | 60 | 2550 | 2440 | 52-M52 | 80 | ||

| 2400 | 2420 | 2685 | 2600 | 56-M39 | 62 | 2760 | 2650 | 56-M52 | 82 | ||

| 2600 | 2620 | 450 | 80 | 2905 | 2810 | 60-M45 | 64 | 2960 | 2850 | 60-M52 | 88 |

| 2800 | 2820 | 3115 | 3020 | 64-M45 | 68 | 3180 | 3070 | 64-M52 | 94 | ||

| 3000 | 3020 | 3315 | 3220 | 68-M45 | 70 | 3405 | 3290 | 68-M56 | 100 | ||

| 3200 | 3220 | 3525 | 3430 | 72-M45 | 76 | ||||||

Sort:0

Metallic Pipe Expansion Joints

Sort:0

PTFE-Lined Rubber Expansion Joint

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99

High Chromium Alloy Lined Pipe

Sort:99