High-performance Abrasion-resistant Offset Transitions

Ceramic sleeve lined offset pipes with high-alumina or zta sleeves for extreme abrasion resistance in offset transitions.

High-performance Abrasion-resistant Offset Transitions

Ceramic sleeve lined offset pipes with high-alumina or zta sleeves for extreme abrasion resistance in offset transitions.

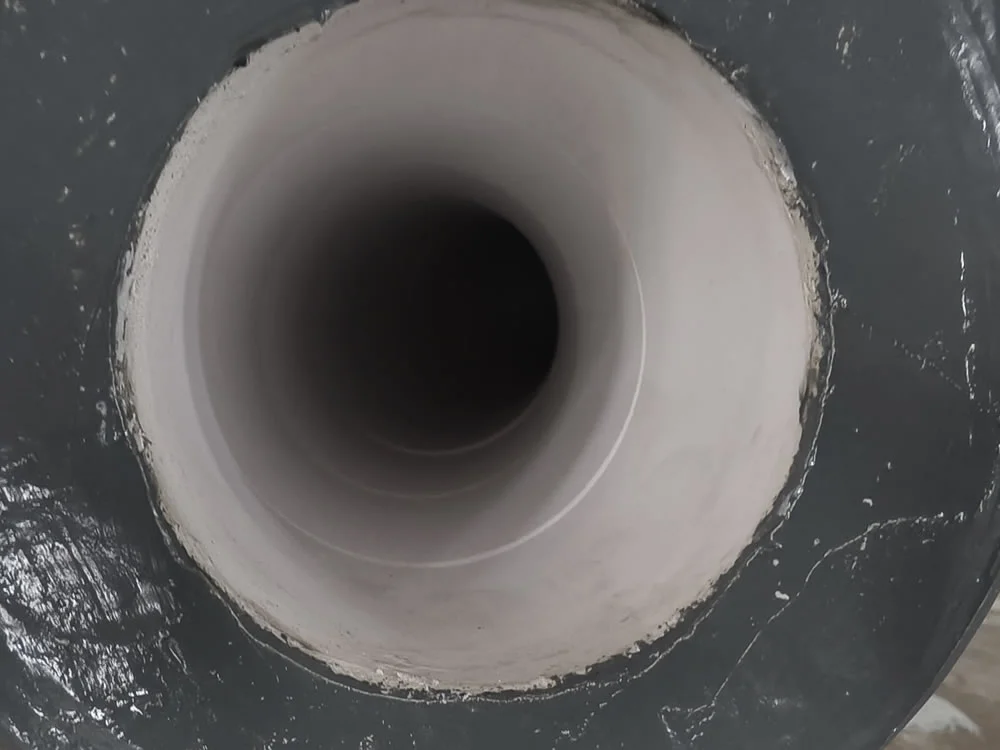

Ceramic sleeve lined offset pipes provide abrasion-resistant transitions for changing pipeline centerline (lateral offset) while bypassing obstacles or aligning equipment. High-purity alumina or zirconia-toughened alumina (ZTA) sleeves are inserted and bonded inside carbon steel offset sections.

Ideal for pneumatic conveying, slurry lines, and systems requiring offset routing without compromising wear protection. Custom offset distances and angles ensure precise fit.

Carbon steel sections welded or formed into offset configuration.

Precision-machined alumina/ZTA sleeves; segmented for complex offsets.

Sleeves inserted with tight fit; bonded using high-temp adhesive/grout.

Dimensional accuracy, bond integrity, and surface inspection.

Wear Resistant Ceramic Lined Pipe Bend

Sort:0

Alumina Ceramic Sleeve Lined Pipe with Flange

Sort:0

Ceramic Sleeve Lined Pipe Bend

Sort:0

Alumina Ceramic Lined Elbow with Loop Flange

Sort:0

Alumina Ceramic Sleeve Lined Pipe Bend

Sort:0

Alumina Ceramic Sleeve Lined Pipe Elbow

Sort:0

Wearback Ceramic Sleeve Lined Elbow

Sort:0

Ceramic Sleeve Lined Bent Pipe

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99