High-performance Abrasion-resistant Pipe Bends

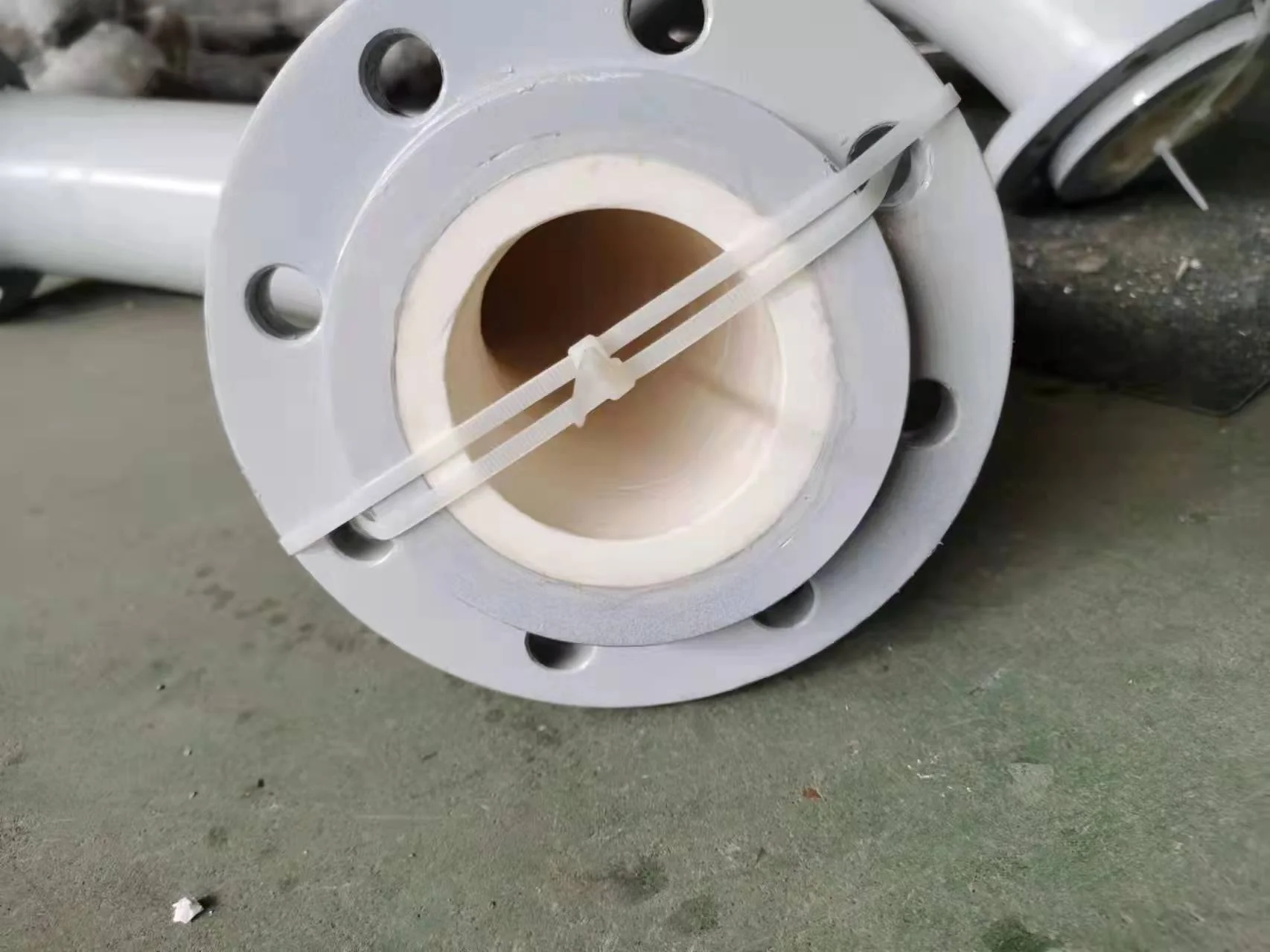

Ceramic sleeve lined bent pipes feature precision-fitted alumina or zta ceramic sleeves inside steel bends for full 360° wear protection.

High-performance Abrasion-resistant Pipe Bends

Ceramic sleeve lined bent pipes feature precision-fitted alumina or zta ceramic sleeves inside steel bends for full 360° wear protection.

Ceramic sleeve lined bent pipes provide superior abrasion resistance in directional changes where turbulence accelerates wear. High-purity alumina or zirconia-toughened alumina (ZTA) sleeves are inserted and securely bonded inside carbon steel bends.

Ideal for pneumatic conveying, slurry pipelines, ash handling, and any system with high-wear bends. Custom radii and angles optimize flow while maximizing lifespan.

Carbon steel pipe formed into bend via induction bending or segmented welding.

Precision-machined alumina/ZTA sleeves; one-piece for small radii or segmented for larger.

Sleeves inserted with tight tolerance; bonded using high-temperature adhesive/grout and end retention.

Dimensional verification, bond testing, surface inspection.

| Parameter | Specification |

|---|---|

| Ceramic Material | 92-95% Al2O3 or ZTA |

| Sleeve Thickness | 10-50 mm |

| Base Material | Carbon Steel (A106, API 5L) |

| Diameter Range | DN100-DN1200 |

| Angles | 22.5°, 45°, 90° (custom) |

| Radius | 1D-10D |

| Temperature | Up to 1500°C |

| Ends | Flanged, Welded, Plain |

Wear Resistant Ceramic Lined Pipe Bend

Sort:0

Alumina Ceramic Sleeve Lined Pipe with Flange

Sort:0

Ceramic Sleeve Lined Pipe Bend

Sort:0

Alumina Ceramic Lined Elbow with Loop Flange

Sort:0

Alumina Ceramic Sleeve Lined Pipe Bend

Sort:0

Alumina Ceramic Sleeve Lined Pipe Elbow

Sort:0

Wearback Ceramic Sleeve Lined Elbow

Sort:0

Ceramic Sleeve Lined Offset Pipe

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99