Types And Working Principle

Grooved couplings provide a fast, reliable mechanical method for joining pipes without welding or threading.

Types And Working Principle

Grooved couplings provide a fast, reliable mechanical method for joining pipes without welding or threading. they accommodate misalignment, vibration, and thermal expansion while ensuring leak-tight seals—widely used in fire protection, hvac, plumbing, mining, and industrial piping.

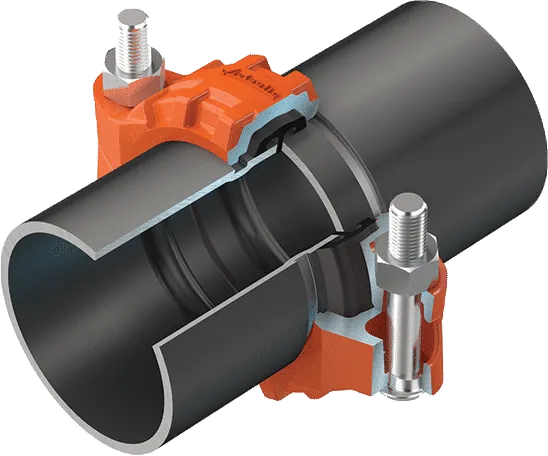

Grooved couplings are mechanical pipe joining systems consisting of a housing, gasket, bolts, and nuts that engage grooves rolled or cut into pipe ends. They create a secure, pressure-resistant joint faster than welding or threading, with built-in flexibility for system movement.

The gasket forms a leak-tight seal, while housing keys prevent pull-out—providing pressure resistance and system integrity.

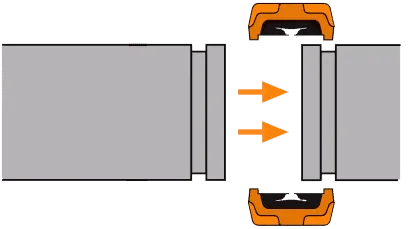

Rigid couplings lock movement; flexible allow angular deflection and axial shift.

Roll or cut grooves into pipe ends to create a secure seal.

Elastomer gasket seats in housing and around grooves.

Two-part housing encircles pipes and gasket.

Tighten bolts/nuts to specified torque—compressing gasket for seal while housing keys engage grooves for restraint.

Grooved couplings offer fast, reliable mechanical pipe joining. Here are the 6 primary types, their characteristics, and applications—summarized for quick reference in fire protection, HVAC, plumbing, and industrial systems.

Locks pipes together with no movement allowed—similar to welded or flanged joints. Ideal for stable runs and risers.

Allows angular deflection, axial movement, and rotation. Absorbs vibration and thermal expansion—most common type.

Connects pipes of different diameters. Available in rigid or flexible versions for size transitions.

Provides a threaded or grooved branch outlet for sprinklers, drains, or instruments.

Joins grooved pipe to threaded, flanged, or plain-end pipe for system integration.

Connects grooved pipe directly to flanged components (ANSI/Class 150/300) without separate flange.

Advantages

Why Choose Grooved Over Threaded or Flanged?

Grooved fittings provide a modern mechanical joining solution that outperforms traditional methods in speed, flexibility, safety, and cost-efficiency—widely used in fire protection, HVAC, plumbing, and industrial piping systems.

Good corrosion resistance, often used in plumbing applications.

Corrosion ResistantExcellent corrosion resistance, suitable for harsh environments and high-purity applications.

Premium GradeCost-effective solution for general purpose applications with good durability.

Cost EffectiveLightweight with good corrosion resistance, used where weight is a concern.

LightweightGood conductivity and corrosion resistance, often used in water systems.

ConductiveDurable with good corrosion resistance, used in marine and industrial applications.

Marine Grade

Besides being used as an important pipe fitting, couplings are also used in the following:

Precise power transmission and motion control in machining operations.

Critical for robotic axes and automated processes in manufacturing.

Ensuring accurate and smooth operation in printing and packaging equipment.

Precision in CNC milling and grinding operations for manufacturing excellence.

Reliable and continuous operation in packaging and assembly lines.

Secure and leak-proof connections for fluid and gas flow systems.

Sort:0

Sort:0

High-Efficiency Anti-Corrosion Boiler Pipeline Protection Rings

Sort:0

Customized Alumina Ceramic Lined Project

Sort:99