High-alumina Conveyor Belt Scrapers

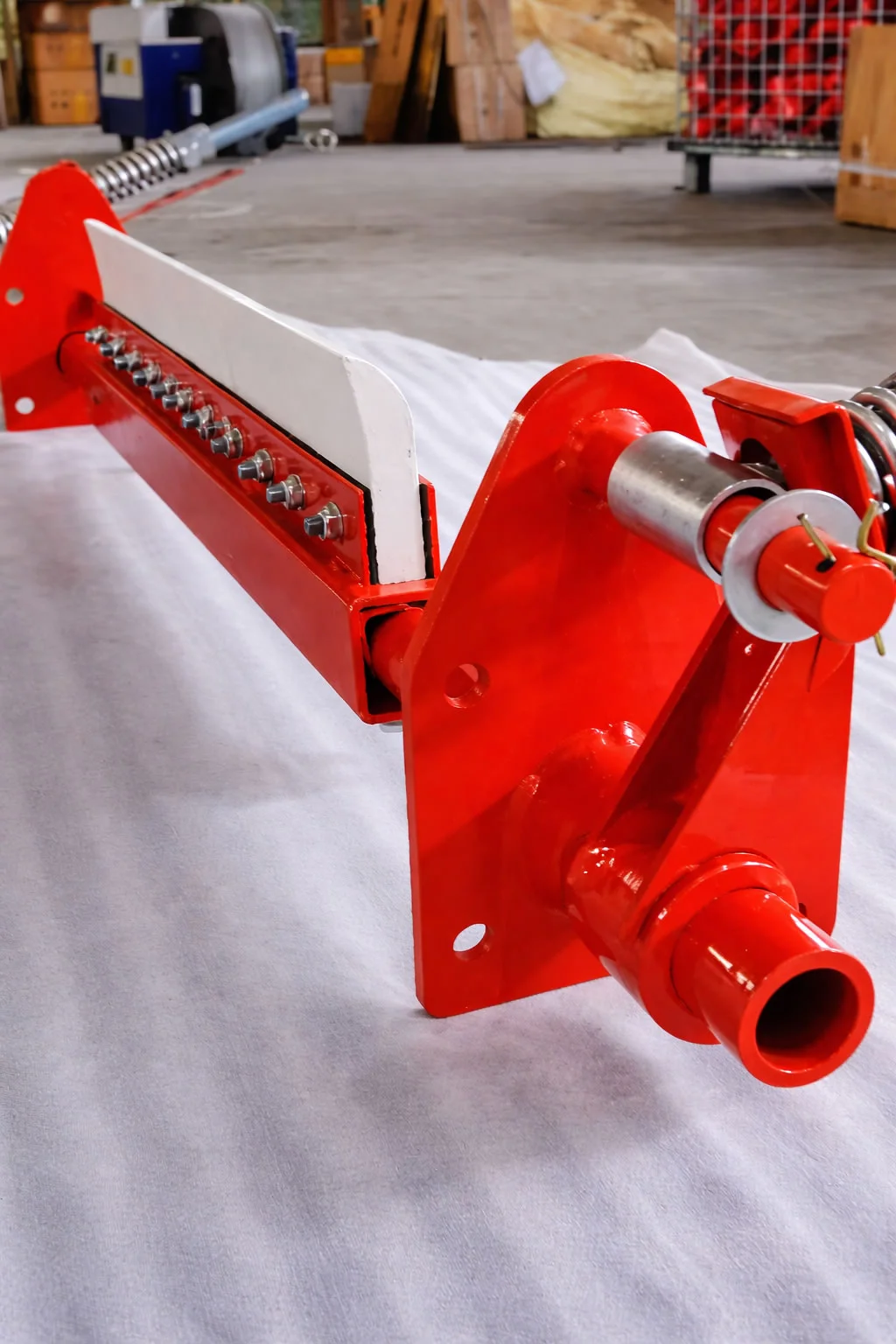

Ceramic belt cleaners feature embedded alumina ceramic tiles in polyurethane or steel blades for extreme abrasion resistance.

High-alumina Conveyor Belt Scrapers

Ceramic belt cleaners feature embedded alumina ceramic tiles in polyurethane or steel blades for extreme abrasion resistance. effectively remove carryback while minimizing belt wear—ideal for heavy-duty conveyors.

Ceramic belt cleaners are advanced scrapers with high-alumina ceramic segments embedded in a flexible base (polyurethane or rubber) or steel frame. They provide superior cleaning performance in abrasive, sticky, or wet materials where standard urethane blades wear quickly.

Ceramic belt cleaners feature embedded alumina ceramic tiles in polyurethane or steel blades for extreme abrasion resistance. Effectively remove carryback while minimizing belt wear—ideal for heavy-duty conveyors.

Primary cleaners at head pulley; secondary for fine cleaning. Self-adjusting tensioners maintain constant blade pressure.

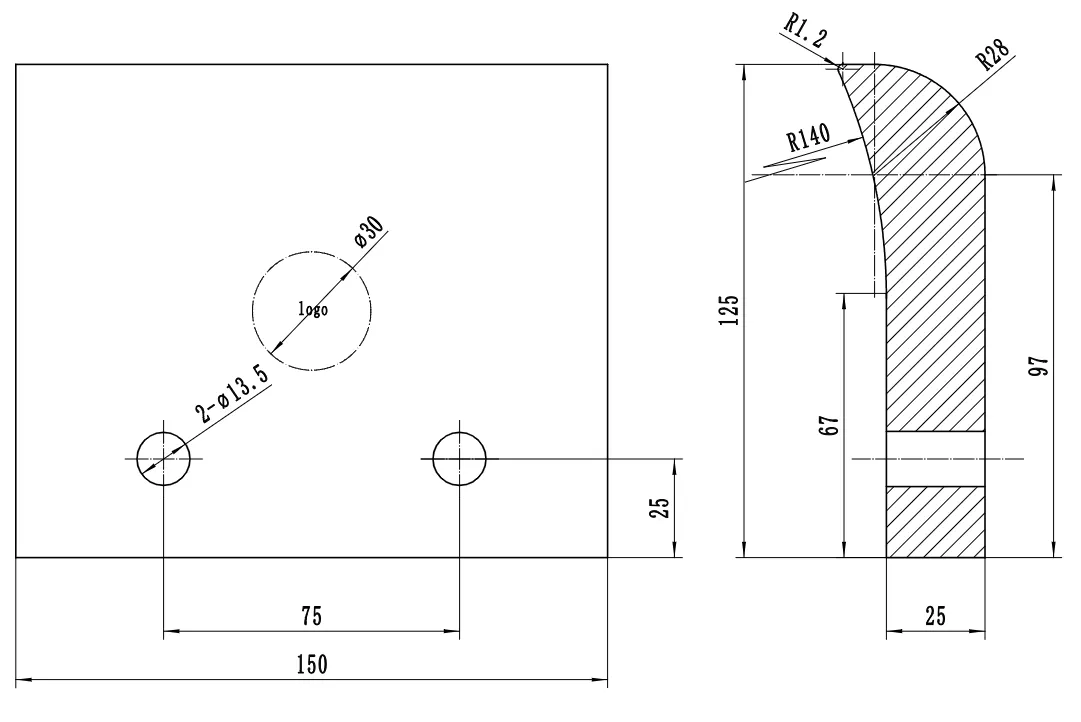

| Parameter | Specification |

|---|---|

| Ceramic Material | 92-95% Al2O3 |

| Hardness | Mohs 9 |

| Blade Types | Primary (head pulley), Secondary (V-plow optional) |

| Belt Width | 450-2400 mm (18"-96") |

| Tensioner | Spring, air, or mechanical |

| Base Material | Polyurethane or Steel Frame |

| Temperature | -40°C to +80°C |

| Applications | Abrasive, wet, sticky materials |

Ceramic tiles are composite product developed with advanced technology, combining a durable steel shell and an inner lining of wear-resistant ceramic for superior performance and extended lifespan.

Using interlocking ceramic tubes bonded with high-strength adhesives and supported by welded steel fixtures, the design ensures reliable protection against abrasion. These pipes offer flexible installation, high durability, and cost-effective wear solutions.

Rockwell hardness of high alumina ceramics reaches HRA80–90, second only to diamond and significantly surpassing stainless and wear-resistant steels.

High alumina ceramics are 266 times more wear-resistant than manganese steel and 171.5 times more than high chromium cast iron, extending equipment service life over 10x.

With a stable inorganic oxide structure, high alumina ceramics resist acid, alkali, salt, and organic solvents without electrochemical corrosion.

High alumina ceramics can operate at temperatures up to 1400°C, suitable for extreme thermal environments.

Its smooth surface and low roughness (1/6 of steel) reduce flow resistance and prevent adhesion, supporting higher flow efficiency.

With density around 3.6g/cm³, high alumina ceramics are lighter than steel, simplifying transport and installation processes.

Customized Alumina Ceramic Lined Project

Sort:99

Ceramic Tile Lined Wear Resistant Multi-Pass Pipe

Sort:0

Wear Resistant Pipe Lined by High Alumina Ceramic

Sort:0

Wear Resistant Ceramic Lined Steel Piping System

Sort:0

Large Diameter Ceramic Lined Tile Pipe

Sort:0

Abrasive Materials Ceramic Lined Bend Pipe

Sort:0

Large Diameter Ceramic Patch Composite Pipe

Sort:0

Ceramic Chip Lined Wear Resistant Pipes

Sort:0

Al2O3 Wear and Corrosion Resistant Seamless Steel Pipe

Sort:0

Wear Resistance Composite Alumina Ceramic Lined Steel Pipe

Sort:0