Tag#for High Chromium Cast Iron Get: 6 results

Rare earth alloy wear resistant high chromium cast iron pipe combines the hardness of high chromium cast iron with rare earth element enhancements for exceptional abrasion and corrosion resistance in harsh industrial environments.

Wear resistant high chromium cast iron pipes provide exceptional hardness and abrasion resistance, ideal for transporting abrasive materials in power plants, mining, and cement industries.

Kmtbcr26 is a high chromium wear resistant cast iron with hardness up to hrc 65, ideal for severe abrasive applications in mining, cement and power plants.

Our high chromium grinding roller, crafted from high chromium cast iron, delivers outstanding crack resistance and wear resistance.

Wear-resistant high chromium cast iron pipes are bimetal pipes with an outer layer of Q235 ordinary steel and an inner lining of high chromium alloy. Manufactured using centrifugal casting, these pipe

Bimetal clad elbows with high chromium cast iron offer superior wear and corrosion resistance for thermal power plants. Contact us for durable, cost-effective solutions!

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

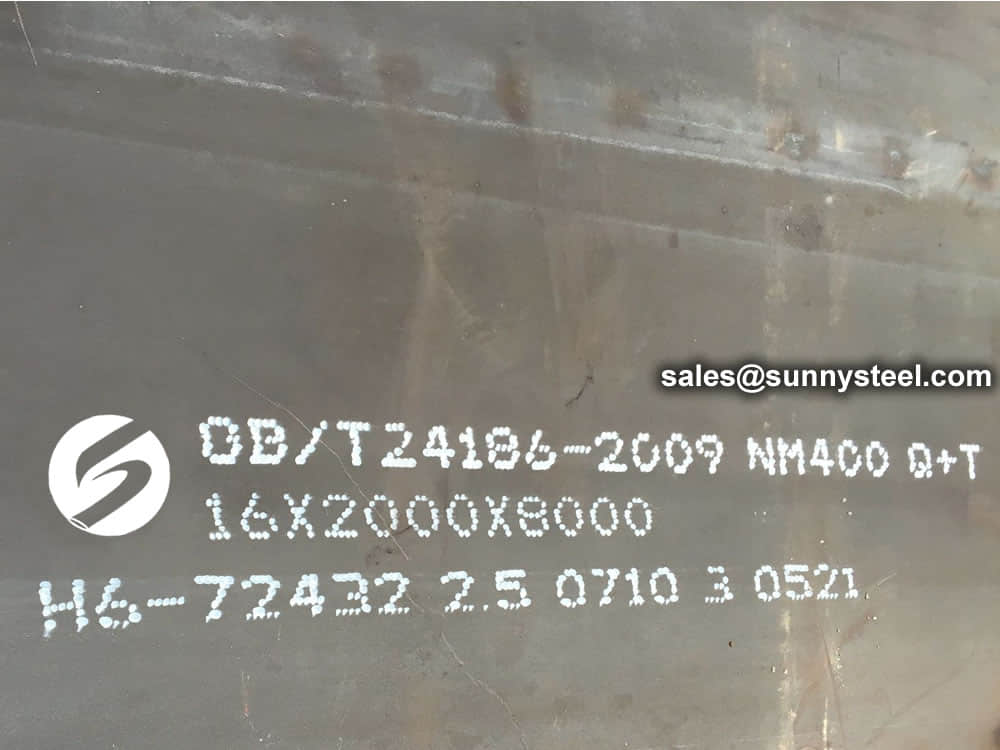

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.