Keywords#for Expansion Joints Get: 18 results / Total 2 pages

Rubber expansion joints absorb vibration, reduce noise, and compensate for thermal expansion in industrial piping, ensuring corrosion resistance and pipeline durability.

Sleeve compensators provide reliable axial movement compensation and corrosion resistance for industrial piping, ensuring durability in high-pressure and high-temperature systems.

Flexible expansion joints absorb thermal expansion and vibration in industrial piping, offering corrosion resistance and durability for high-pressure applications.

Metal expansion joints absorb thermal expansion and vibration in industrial piping, offering corrosion resistance and durability for high-pressure applications.

Bellows expansion joints absorb thermal expansion and vibration in industrial piping, offering corrosion resistance and durability for high-pressure applications.

Metallic pipe expansion joints provide flexible, corrosion-resistant solutions for industrial piping, absorbing thermal expansion and vibration to ensure system durability.

Food grade rubber expansion joints ensure hygienic, flexible connections in food and beverage piping, offering corrosion resistance and vibration control for sanitary applications.

Ptfe-lined rubber expansion joints provide corrosion resistance and flexibility for industrial piping, absorbing vibration and thermal expansion in harsh environments.

Explore single flow sleeve compensators designed to absorb thermal expansion in pipelines, ensuring stress relief and durability. ideal for industrial applications, these axial expansion joints offer corrosion resistance and low maintenance.

A non-thrust sleeve compensator is a type of expansion joint used in piping systems to accommodate thermal expansion and contraction without generating axial thrust forces.

Discover high-performance rotary compensators designed to absorb thermal expansion and vibrations in pipelines. these durable rotary expansion joints ensure stress relief, corrosion resistance, and easy maintenance for industrial piping systems.

Ceramic‑lined sleeve expansion joints protect against abrasion, corrosion, and thermal stress—ideal for high‑wear pipeline systems with movement and vibration.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

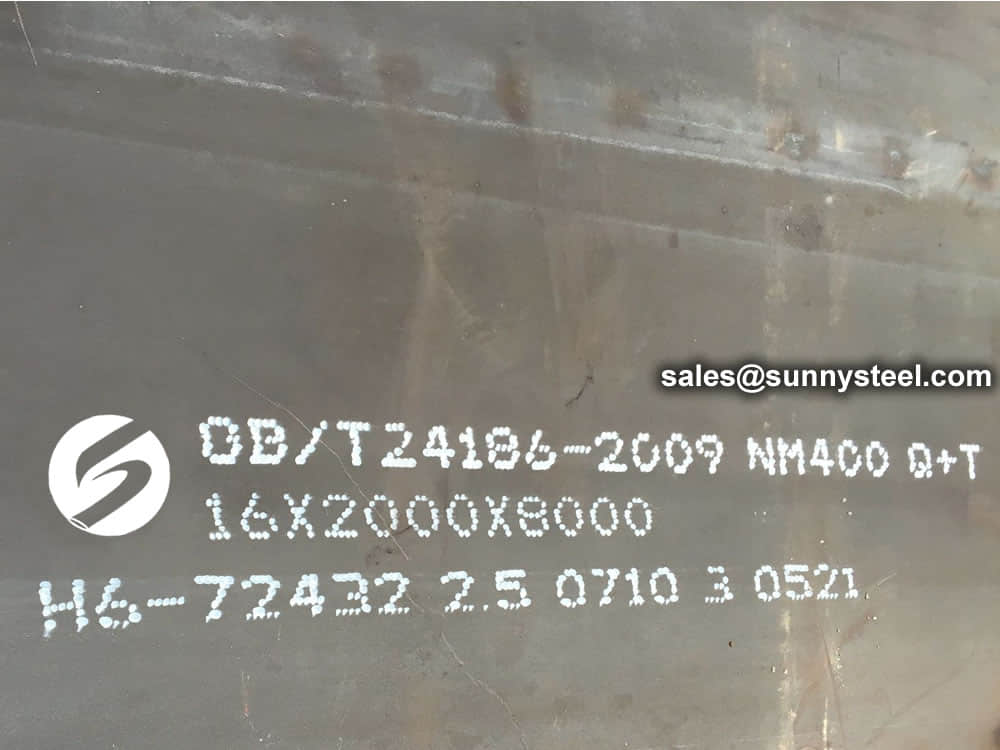

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.