Premium Heat & Corrosion-resistant Protection For Boiler Tubes

1cr25ni20si2 tube shields provide outstanding high-temperature and corrosion resistance, making them ideal for shielding boiler tubes in extreme flue gas environments.

Premium Heat & Corrosion-resistant Protection For Boiler Tubes

1cr25ni20si2 tube shields provide outstanding high-temperature and corrosion resistance, making them ideal for shielding boiler tubes in extreme flue gas environments.

1Cr25Ni20Si2 tube shields, also known as boiler tube shields, anti-erosion shields, or anti-corrosion shields, are critical components engineered to protect boiler tubes from erosion, corrosion, and abrasion caused by high-temperature flue gases and fly ash. These shields are widely applied in power plants, waste-to-energy systems, and petrochemical boilers operating under extreme thermal and chemical conditions.

Manufactured from 1Cr25Ni20Si2 stainless steel—a heat-resistant alloy containing approximately 25% chromium, 20% nickel, and 2% silicon—the shields provide outstanding oxidation resistance and structural stability at temperatures up to 1100°C. Silicon enhances the formation of a protective oxide film, while chromium and nickel improve high-temperature corrosion resistance and mechanical strength. Note: embrittlement may occur in the 600–800°C range.

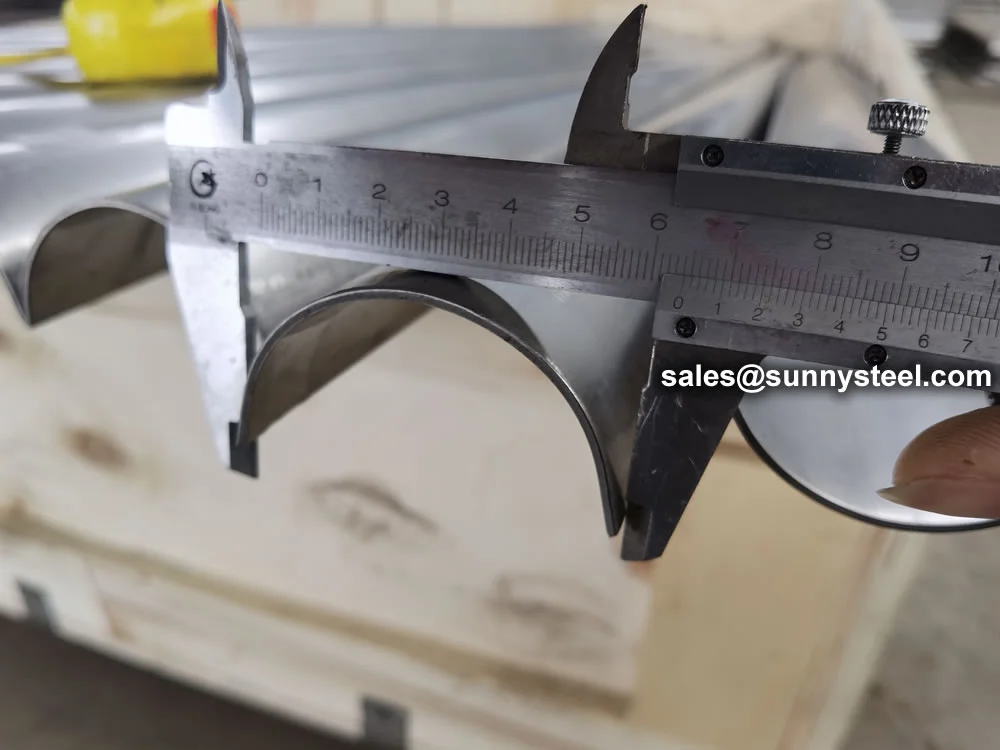

Available in various forms—straight, inner-curve, outer-curve, side-curve, and S-curve—these shields are customized to fit boiler tubes with outer diameters ranging from 32mm to 89mm. Common lengths range from 1000mm to 2000mm, with wrap angles from 90° to 240°. The shield’s internal diameter is typically 1–3mm larger than the tube it covers, ensuring a snug and reliable fit.

High-precision bending, stamping, and mold shaping processes are used to produce smooth, weldable surfaces. Snap rings made from 1Cr25Ni20Si2 or similar alloys are spot-welded every 200–500mm along the shield’s arc to ensure secure placement. Coatings such as chromium carbide may be applied to further enhance surface wear resistance for ultra-harsh conditions.

These shields play a vital role in reducing unplanned maintenance, extending tube life, and increasing thermal system reliability. Applications include superheaters, reheaters, economizers, and water-cooled walls in circulating fluidized bed (CFB) boilers, biomass plants, and fossil-fuel systems. Each shield complies with GB 4238 (heat-resisting steel sheets) and GB/T 1221 (heat-resisting steel bars), and undergoes PMI verification to ensure compliance.

Compared to standard stainless grades such as SS304 or SS321, 1Cr25Ni20Si2 offers superior resistance to thermal cycling, intergranular corrosion, and chemical attack in aggressive flue gas environments. It’s the optimal solution for extending service life and reducing boiler maintenance frequency in extreme industrial conditions.

1Cr25Ni20Si2 is an austenitic stainless steel with excellent high-temperature strength and oxidation resistance. However, it is sensitive to sulfur-containing environments and exhibits precipitation embrittlement in the range of 600–800°C, making it ideal for manufacturing furnace components under stress.

| Grade | C | Si | Mn | S | P | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 1Cr25Ni20Si2 | ≤0.20 | 1.50–2.50 | ≤1.50 | ≤0.030 | ≤0.035 | 24.00–27.00 | 18.00–21.00 |

| EU (EN) | USA (ASTM) | Germany (DIN) | Japan (JIS) | France (AFNOR) | UK (BS) | Italy (UNI) | China (GB) | Sweden (SS) | Czech (ČSN) | Russia (GOST) | ISO |

|---|---|---|---|---|---|---|---|---|---|---|---|

| X8CrNi25-21 (1.4845) | 310S / S31008 | X8CrNi25-21 | SUS310S | Z8CN25-20 | 310S16 / 310S24 / 310S31 | X6CrNi25-20 | 1Cr25Ni20Si2 | 2361 | 17255 | 10KH23N18 / 20KH23N18 | H16 |

1Cr25Ni20Si2 (China GB) corresponds to EN 1.4845 / X8CrNi25-21 and is similar to 310S stainless steel in other systems.

| Property | Value |

|---|---|

| Tensile Strength (MPa) | ≥ 590 |

| Yield Strength 0.2% (MPa) | ≥ 295 |

| Elongation at Break (%) | ≥ 35 |

| Reduction of Area (%) | ≥ 50 |

| Brinell Hardness (HB) | ≤ 187 |

276 visits

226 visits