Superior Wear Protection For Branch Connections

Ceramic sleeve lined pipe tees provide outstanding wear and corrosion resistance at high-stress junctions, ensuring long service life in abrasive flow systems.

Superior Wear Protection For Branch Connections

Ceramic sleeve lined pipe tees provide outstanding wear and corrosion resistance at high-stress junctions, ensuring long service life in abrasive flow systems.

Alumina sleeves (Mohs 9) withstand abrasion from slurry, ash, and dry particles.

Carbon steel shell ensures strength under high-pressure and heavy-duty conditions.

Engineered to handle turbulence and prevent rapid erosion at tee junctions.

Available in equal and reducing tee formats with flanged or welded ends.

Performs in extreme conditions up to 800°C and corrosive chemical exposure.

| Ceramic Material | Alumina (92%–95% Al₂O₃) |

|---|---|

| Outer Body Material | Q235 / Q345 Carbon Steel |

| Liner Hardness | Mohs 9 |

| Pipe Sizes | DN50 – DN800 |

| Max Operating Temperature | Up to 800°C |

| Max Pressure | Up to 2.5 MPa |

| Tee Types | Equal Tee / Reducing Tee |

| Connection Options | Flanged, Grooved, Welded |

| Installation Method | Shrink-fit or bonded ceramic sleeves |

Sunny Steel specializes in custom fabrication of ceramic sleeve lined tees with tailored diameters, pressure classes, and connection types. From engineering consultation to global delivery, we ensure your wear-critical junctions remain protected and operational.

Ceramic sleeves lined pipes combine the strength o...

Wear resistant ceramic lined pipe bends provide un...

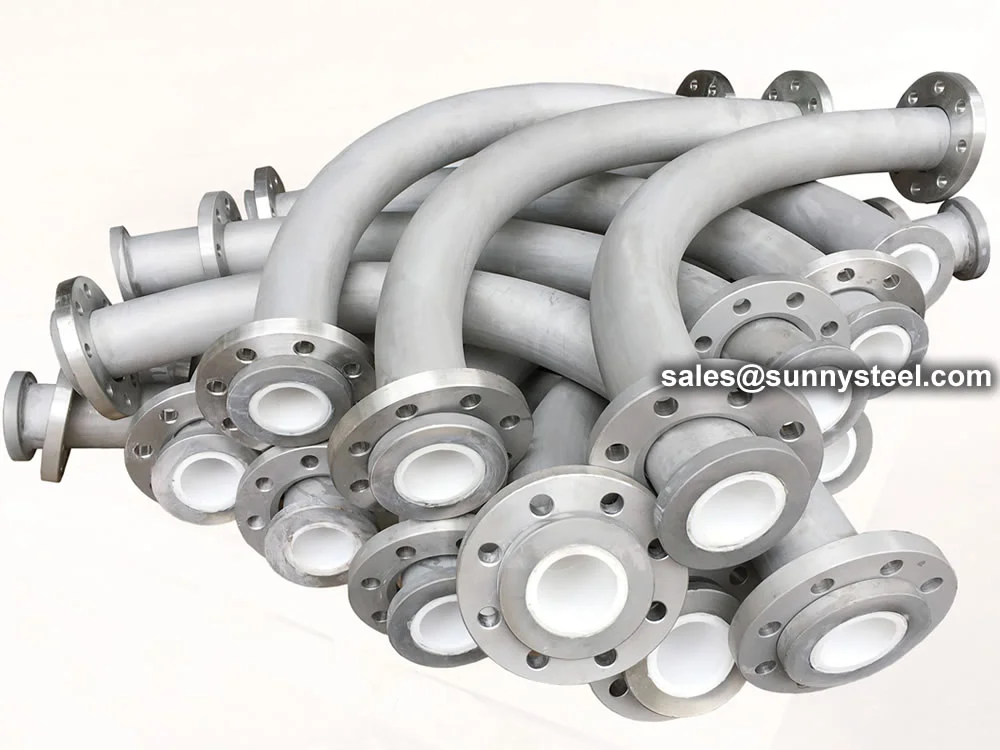

Ceramic sleeve lined pipe bends provide superior p...

Alumina ceramic sleeve lined pipe bends offer outs...