Premium Al₂o₃ Ceramic Offering Exceptional Hardness And Chemical Stability

Aluminum oxide (al₂o₃) ceramic provides outstanding wear resistance and chemical stability for industrial abrasion and corrosion protection.

Premium Al₂o₃ Ceramic Offering Exceptional Hardness And Chemical Stability

Aluminum oxide (al₂o₃) ceramic provides outstanding wear resistance and chemical stability for industrial abrasion and corrosion protection.

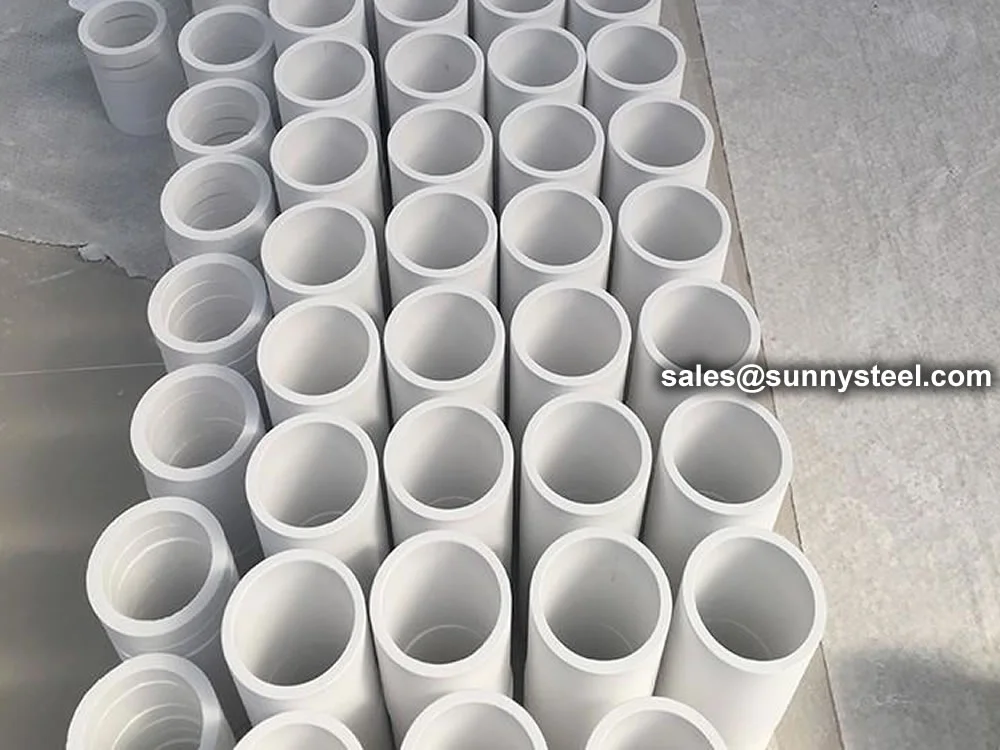

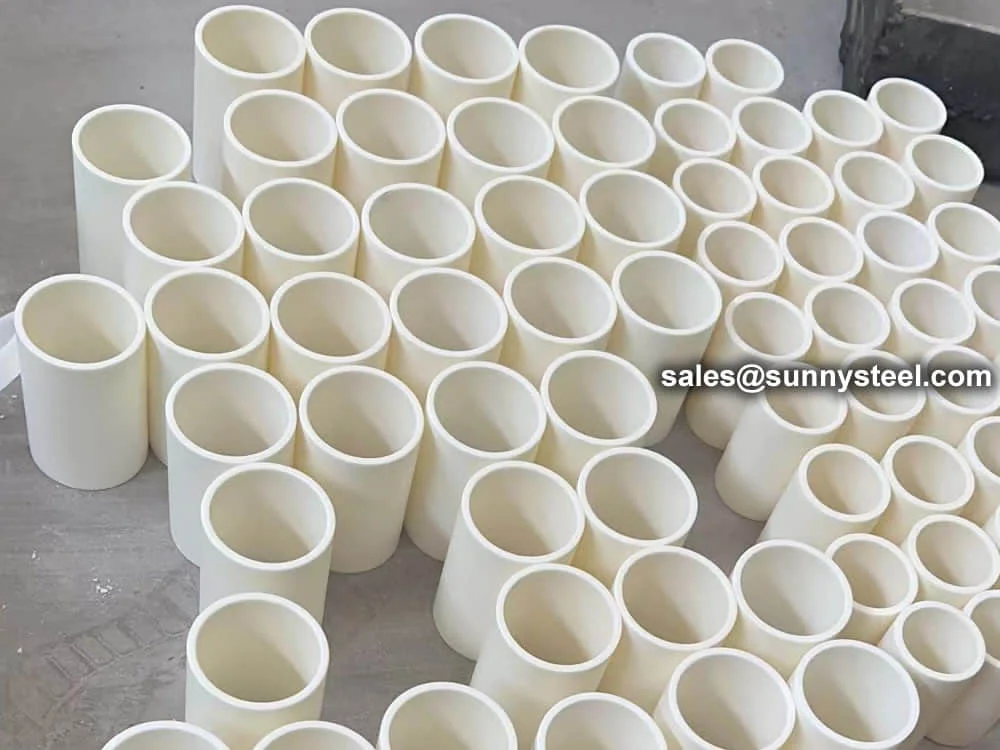

Aluminum oxide ceramic is a widely used advanced material known for its outstanding hardness, chemical resistance, and high thermal stability. With a Mohs hardness of 9, Al₂O₃ ceramics provide exceptional wear resistance in industrial environments exposed to abrasion, corrosion, and high temperatures.

Typical applications include linings for pipes, pumps, and valves in mining, power generation, cement, and chemical processing. Manufactured using advanced sintering technologies, these ceramics offer excellent dimensional precision, long service life, and cost efficiency.

Mohs hardness of 9 makes alumina highly resistant to abrasion and mechanical wear.

Maintains mechanical performance in continuous use up to 1700°C.

Excellent dielectric strength for use in electronics and high-voltage environments.

Resistant to acids, alkalis, and solvents — ideal for corrosive process conditions.

Supports heat dissipation in high-load and thermally active applications.

Safe for use in medical implants and surgical tools due to excellent tissue compatibility.

Affordable alternative to zirconia or silicon carbide in many engineering applications.

Substrates for integrated circuits, insulating components, and heat-resistant housings.

Pump seals, valves, and cutting tools exposed to abrasive or erosive media.

Used in orthopedic implants, dental components, and bioinert coatings.

Kiln furniture, furnace linings, and thermocouple protection tubes.

Corrosion-resistant nozzles, pipes, and linings in chemical reactors and scrubbers.

Lightweight, high-strength insulators and components in propulsion systems.

Alumina is widely used in grinding wheels, sandpapers, and polishing tools.

| Material | Unit | 95% Al2O3 | 96% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | 99.8% Al2O3 |

|---|---|---|---|---|---|---|

| Purity | % | 95 | 96 | 99 | 99.5 | 99.8 |

| Color | --- | White/Pink | White | Ivory | Ivory | Ivory |

| Density | g/cm³ | 3.65 | 3.72 | 3.85 | 3.90 | 3.92 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0 |

| Moh's Hardness | --- | 9 | 9 | 9 | 9 | 9 |

| HV Hardness | --- | >1300 | >1300 | 1700 | 1750 | 1800 |

| Flexural Strength @25°C | MPa | 300 | 300 | 330 | 375 | 390 |

| Fracture Toughness | MPa·m1/2 | 3~4 | 3~4 | 3~4 | 4 | 4 |

| Compressive Strength (25°C) | MPa | 2200 | 2200 | 2350 | 2450 | 2500 |

| Thermal Conductivity @25°C | W/m·K | 18–22 | ≥24 | 27 | 29 | 32 |

| Thermal Expansion Coefficient (25–1000°C) | 10-6/°C | 8 | 8 | 8 | 8 | 8 |

| Thermal Shock Resistance | ΔT (°C) | 220 | 220 | 180–200 | 180–200 | 180–200 |

| Max. Working Temperature | °C | 1500 | 1500 | 1700 | 1750 | 1750 |

| Dielectric Strength | kV/mm | 16 | 17.2 | 20 | 22 | 22 |

| Electrical Resistivity @25°C | Ω·cm | 1014 | 1014 | 1014 | 1014 | 1014 |

| Dielectric Constant @1MHz | --- | 9 | 9 | 9.7 | 9.7 | 9.8 |

| Dielectric Loss (Tan δ) @1MHz | --- | 0.0004 | 0.0002 | 0.0002 | 0.0001 | 0.0001 |

Compare physical, thermal, and electrical properties across various purity levels of alumina ceramic (Al2O3).

| Parameter | Details |

|---|---|

| Material Options | Alumina (40%–99.8%), Zirconia, Silicon Carbide, Silicon Nitride |

| Forming Methods | Extrusion, Dry Pressed, Hot Pressed, CIM, ISO Pressed |

| Dimensional Capability | Min. ID: 1mm; Max. OD: 800mm |

| Dimensional Tolerance | OD ±0.005mm, ID ±0.01mm, Length ±0.001mm |

| Surface Treatment | Polished, Glazed, or Metalized |

| Secondary Processing | CNC machining, lapping, threading, drilling, grinding, laser cutting |

Standard manufacturing capabilities and tolerances for ceramic tube products.

Wear-resistant alumina ceramic rings offer excelle...

Alumina ceramic cyclone liner tubes offer superior...

95% al₂o₃ ceramic sleeves provide exceptional hard...

Alumina ceramic lined components provide superior ...

Alumina ceramic insulation pipes provide superior ...