Seamless And Welded Carbon Steel Elbows For Cost-effective Piping Applications

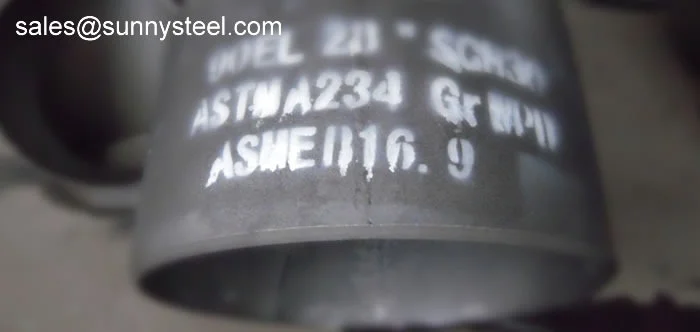

Carbon steel elbows are robust pipe fittings designed for industrial piping systems, compliant with astm a234 and asme b16.

Seamless And Welded Carbon Steel Elbows For Cost-effective Piping Applications

Carbon steel elbows are robust pipe fittings designed for industrial piping systems, compliant with astm a234 and asme b16.9 standards. these seamless or welded elbows, such as astm a234 wpb, offer excellent strength and erosion resistance, making them ideal for boiler pipeline protection in industries like oil and gas, power generation, and general industrial piping.

Carbon Steel Elbows are robust pipe fittings designed for industrial piping systems, compliant with ASTM A234 and ASME B16.9 standards. These seamless or welded elbows, such as ASTM A234 WPB, offer excellent strength and erosion resistance, making them ideal for boiler pipeline protection in industries like oil and gas, power generation, and general industrial piping.

Carbon steel elbows are manufactured through hot-forming or cold-forming processes, ensuring durability in moderate temperature ranges (-29°C to 425°C). With a composition including carbon (≤0.30%) and manganese (0.29-1.06%), they provide good mechanical strength and moderate corrosion resistance. Available in long-radius (LR, R=1.5D), short-radius (SR, R=1D), and reducing configurations, these elbows support angles of 90°, 45°, and 22.5° for versatile industrial piping designs.

These elbows support welding, bending, and flanging, with good weldability. Available in sizes from 1/2” to 24” (DN15 to DN600) and wall thicknesses from SCH 10 to SCH 160, they meet diverse pipeline requirements. Rigorous testing, including tensile, impact, and hydrostatic tests, ensures compliance with ASTM A234 standards for reliable performance.

Carbon steel elbows can be coated (e.g., FBE, 3LPE, galvanizing) to enhance corrosion resistance, protecting against rust in moderately corrosive environments. Their cost-effectiveness and strength make them ideal for boiler pipeline protection in oil and gas pipelines, power plants, and industrial systems where high corrosion resistance is not critical.

For engineers seeking cost-effective and durable industrial piping solutions, carbon steel elbows deliver reliable performance, addressing challenges like mechanical stress and moderate corrosion in demanding applications.

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤0.30 |

| Manganese (Mn) | 0.29-1.06 |

| Phosphorus (P) | ≤0.050 |

| Sulfur (S) | ≤0.058 |

| Silicon (Si) | ≥0.10 |

| Chromium (Cr) | ≤0.40 |

| Molybdenum (Mo) | ≤0.15 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 415-585 |

| Yield Strength, min (MPa) | 240 |

| Elongation, min (%) | 22 (Longitudinal) |

| Feature | ASTM A234 WPB | ASTM A403 WP304 | ASME SA335 P91 |

|---|---|---|---|

| Material Type | Carbon Steel | Stainless Steel | Alloy Steel |

| Temperature Range | Moderate (-29°C to 425°C) | High (up to 870°C) | High (up to 650°C) |

| Corrosion Resistance | Moderate | Superior (Austenitic) | Excellent (High Cr/Mo/V) |

| Erosion Resistance | Good | Moderate | Excellent |

| Creep Strength | Moderate | Good | Superior |

| Applications | Oil and Gas, Power Plants | Food Processing, Marine | Power Plants, Petrochemical |

| Key Advantage | Cost-effective strength | Superior corrosion resistance | Superior creep strength |

| Material Category | Steel Pipe Grade | Elbow Fitting Grade |

|---|---|---|

| Carbon Steel | A106 Gr A | A234 Gr WPA |

| A106 Gr B | A234 Gr WPB | |

| A106 Gr C | A234 Gr WPC | |

| Carbon Steel – Alloy / High-Temp | A335 Gr P1 | A234 Gr WP1 |

| A335 Gr P11 | A234 Gr WP11 | |

| A335 Gr P12 | A234 Gr WP12 | |

| A335 Gr P22 | A234 Gr WP22 | |

| A335 Gr P5 | A234 Gr WP5 | |

| A335 Gr P9 | A234 Gr WP9 | |

| Low-Temp Carbon Steel Alloy | A333 Gr 6 | A420 Gr WPL6 |

| A333 Gr 3 | A420 Gr WPL3 |

Coatings like FBE and galvanizing enhance resistance to rust.

Robust carbon steel withstands wear in high-flow systems.

High tensile strength (415-585 MPa) for demanding applications.

Good weldability for secure pipeline configurations.

Affordable solution for large-scale industrial piping projects.

Available in LR, SR, and reducing designs for diverse applications.

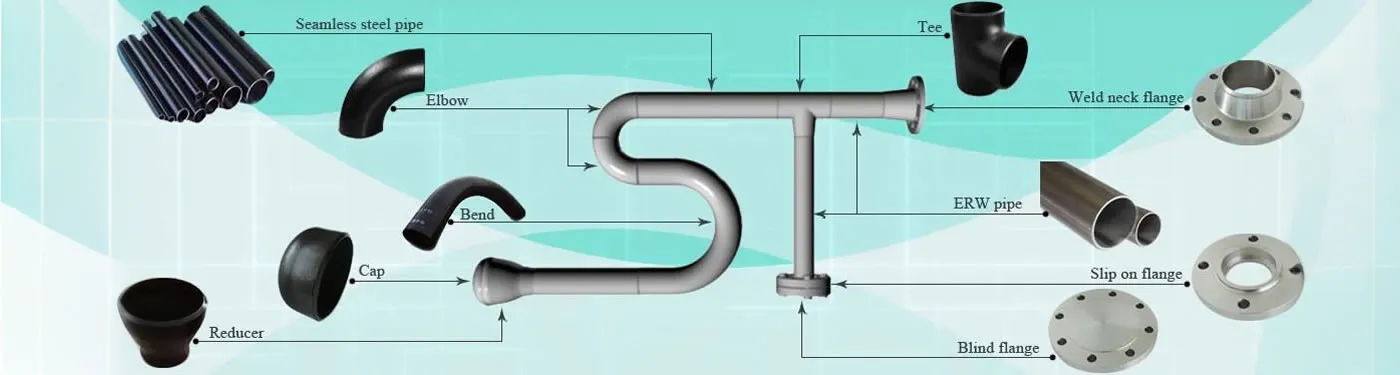

Carbon steel elbows are first classified by their radius of curvature, which can be divided into long radius elbows and short radius elbows.

Depending on pressure rating, 17 schedule levels are available: Sch5s, Sch10s, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS, Sch80, Sch100, Sch120, Sch140, Sch160, XXS. Most commonly used schedules are STD and XS.

Based on the angle, common elbows include: 45°, 90°, and 180°.

Radius of curvature is a measure of how sharply a curve bends. It is defined as the reciprocal of curvature, which itself is the rate of change of the tangent angle with respect to arc length. A smaller radius means a sharper bend, while a larger radius indicates a gentler curve.

For long radius elbows, the radius of curvature must be controlled within tolerance. For instance, if R = 1.5D, the actual curvature should not deviate beyond the specified range.

Carbon Steel: ASTM/ASME A234 WPB, A860 MSS-SP-75 WPHY 42/46/52/56/60/65/70

Low Temperature Steel: ASTM A420 WPL3, A420 WPL6

Size Range: 1/2" to 56" (DN 15 to DN 1400)

Angles Available: 22.5°, 45°, 90°, 180°

A curated list of long-tail keywords for carbon steel elbows, covering specifications, applications, and material properties.

Note: Carbon steel elbows, including ASTM A234 WPB, are designed for cost-effective and durable industrial piping. Contact a certified supplier for detailed specifications.

Formed by hot pressing or forging, directly welded to pipe with beveled ends for full penetration weld. Suitable for high pressure & high temperature pipelines.

Features a socket at the end where the pipe is inserted before welding. The actual end diameter is slightly larger than pipe OD for proper fit.

Similar to socket weld elbows but with threads inside for easy installation & removal. Ideal for repair and maintenance work in low/medium pressure pipelines.

ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

ASTM A234 WPB, WPBW, WPHY 42, 46, 52, 60, 65, 70

ASTM A420 WPL3, A420 WPL6

ASTM / ASME A/SA 234 Gr. WP 1, 5, 9, 11, 12, 22, 91

ASTM A815 / ASME SA815, UNS S31803, S32205, Werkstoff No. 1.4462

ASTM / ASME SB336: UNS 2200 (Nickel 200), 2201 (Nickel 201), 4400 (Monel 400), 8020 (Alloy 20), 8825 (Inconel 825), 6600 (Inconel 600), 6601 (Inconel 601), 6625 (Inconel 625), 10276 (Hastelloy C276)

Industries Using

Carbon Steel Elbow components that are used to connect, join, or adapt different parts of a system, such as pipes, tubes, or hoses. They serve multiple purposes, including:

The choice of fittings depends on the specific requirements of the system, including factors like the type of fluid or gas, pressure, temperature, and the layout of the piping or tubing system.

Astm a192 carbon steel elbows are specialized pipe...

In a long radius elbow, the centreline radius is 1...

Discover short-radius elbows designed for corrosio...

A Reducer Elbow is a fitting used to join two diff...

Explore our high-quality astm a420 wpl6 elbows des...

Explore astm a234 wp22 elbows designed for corrosi...