Get: 9 results / Total 2 pages

Ceramic sleeve lined pipe bends provide superior protection against abrasion, corrosion, and high-impact wear in curved pipeline sections, ensuring extended service life and reduced maintenance.

Alumina ceramic lined elbows with loop flanges offer robust wear protection, easy flange connections, and extended service life in abrasive flow systems like slurry, ash, or chemical pipelines.

Alumina lined elbow ceramic on sale provides durable and abrasion-resistant pipe fittings made with high-purity alumina ceramic, ideal for industrial slurry and abrasive material transport.

Engineered ceramic elbows combining silicon carbide alloy lining and steel outer shell for exceptional abrasion and chemical resistance in industrial pipelines.

Backpack ceramic lined elbow features a 12mm alumina ceramic layer bonded to high-tensile steel, offering 20× longer lifespan vs. standard fittings. ideal for abrasive slurry transport in mining, cement, and ash handling systems. withstands 800°c temperatures and severe impact. custom angles available.

Alumina ceramic sleeve lined elbows provide extreme wear resistance in curved pipe sections, reducing maintenance and extending service life under high-impact slurry and particle flows.

Bimetal clad pipe is cast with mold vanishing vacuum suction casting cladding process.

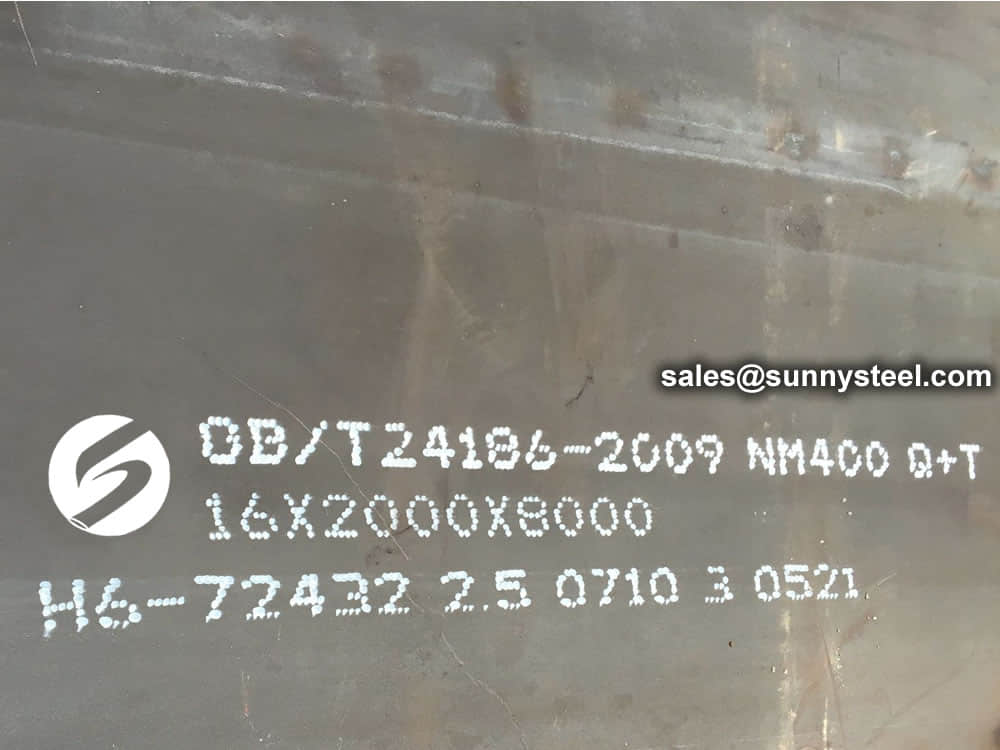

NM400 Steel Plate is a type of wear-resistant steel plate that is commonly used in various industrial applications.

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

The wear resistance of the pulverized coal conveying pipeline of the boiler of the thermal power plant must be designed for leakproof, anti-corrosion, rain-proof, anti-freeze and other factors.