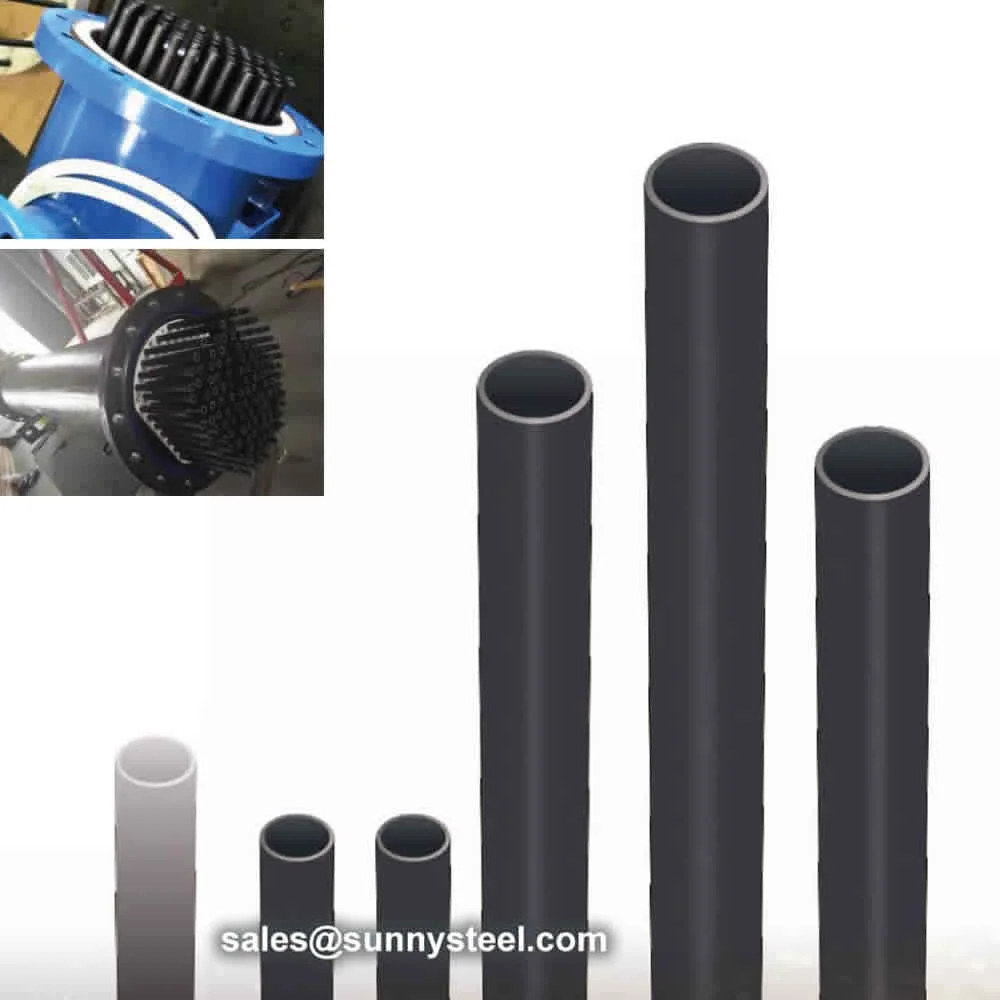

Silicon Carbide For Corrosive & Thermal Systems

Ssic heat exchange tubes deliver outstanding corrosion and thermal shock resistance, ideal for aggressive and high-temperature fluid systems in chemical and thermal industries.

Silicon Carbide For Corrosive & Thermal Systems

Ssic heat exchange tubes deliver outstanding corrosion and thermal shock resistance, ideal for aggressive and high-temperature fluid systems in chemical and thermal industries.

SSiC heat exchange tubes are precision-engineered components made from siliconized silicon carbide, a high-performance ceramic ideal for heat exchanger applications in corrosive and high-temperature environments. These tubes are designed to transfer heat efficiently while maintaining chemical integrity under extreme conditions.

With ultra-high hardness, superior chemical stability, and excellent thermal conductivity, SSiC tubes outperform traditional metallic and polymer-lined heat exchanger materials. They resist damage from acidic gases, saltwater, solvents, and rapid temperature fluctuations.

Maintains integrity in extreme thermal environments

100‑125 W/m·K enables more compact design

Withstands strong acids & alkalis

No binders, no leaching risks

Resists scale buildup more than graphite

Ideal for harsh chemical processes

| Parameter | Specification |

|---|---|

| Pressure Range | Full vacuum to 5 kg/cm² |

| Temperature Range | -50 °C to 200 °C |

| Heat Exchange Area | 0.8 to 50 m² |

| Shell Diameter | DN 100 to DN 500 mm |

| Flange Standard | ANSI 150 |

| Shell Material | Carbon/Stainless Steel |

| Bonnet Lining | PFA lined Carbon/Stainless |

| Tube Sheet | PTFE / GFT / PFA |

| Tubes | Silicon Carbide, 14‑19 OD × 2000 mm |

| Thermal Conductivity | 100–125 W/m·°C |

| Service Types | Gas Condensation / Liquid–Liquid Cooling / Heating |

Silicon Carbide heat exchanger solutions for corrosive media transport in critical industrial sectors

API & bulk drug manufacturing

Specialty chemical production

Sulfuric, hydrofluoric, nitric acids

Sodium hydroxide solutions

Processing hydrogenated chemicals

Brine & organic compound handling

Ideal for high-wear environments with abrasive particles like silica, slag, and mineral slurries

Withstands strong acids (HF, HCl, H2SO4) and alkalis in chemical processing applications

Maintains structural integrity up to 1600°C in oxidizing and reducing atmospheres