Bearing Pipes

Pipes designed for bearing loads, offering high strength and durability.

Honed tube is ready to use for hydraulic cylinder applications without further ID processing.

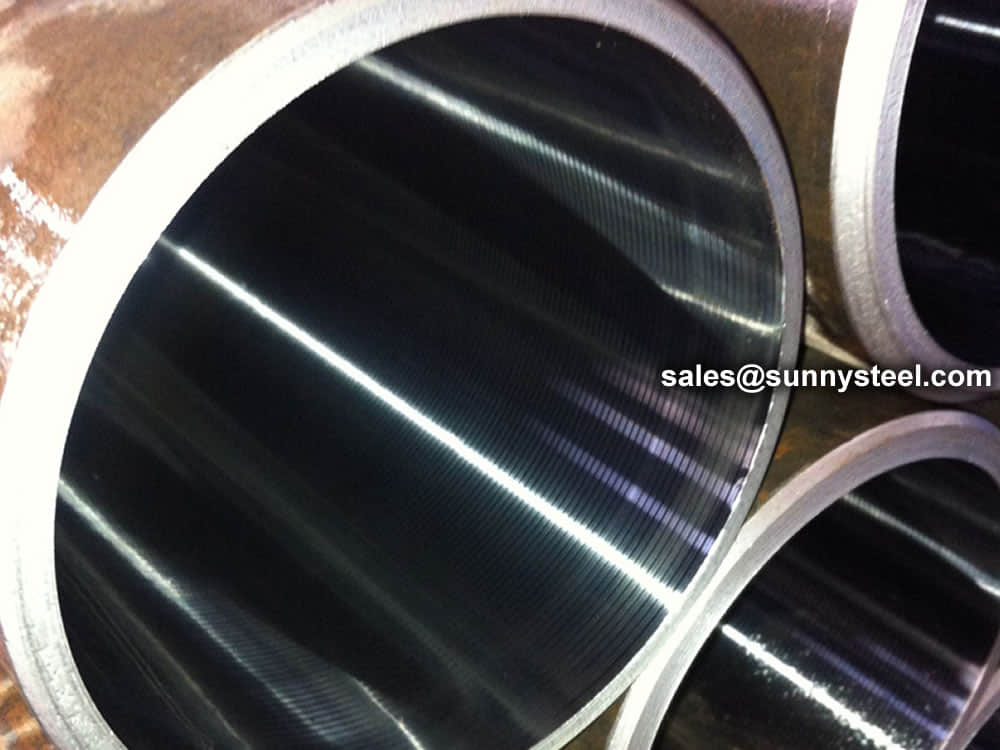

Honed tubes are precision tubes that have been processed to achieve a smooth inner bore and precise internal dimensions. They are commonly used in hydraulic and pneumatic cylinder applications where a high degree of accuracy and surface finish is required.

Honed tube is usually a CDS (Cold drawn seamless) steel tube or DOM (Drawn Over Mandrel) steel tube with inside diameter honed or skived &roller burnished, so honed tubing is with extremely precise ID dimensions and smoothly ID surface.

Honed tubes are broadly utilized to produce and repair hydraulic cylinders and pneumatic cylinders. So in many fields, the honed tube is called cylinder tube also.

Honed tube usually is produced by two main manufacturing process, which are honing process or skiving & roller burnishing process. The mother tube we usually use “Suitable To Hone” Cold Drawn Seamless Tubes. The process of the honed pipe is determined upon the dimension, mold available and the requirement of the customer.

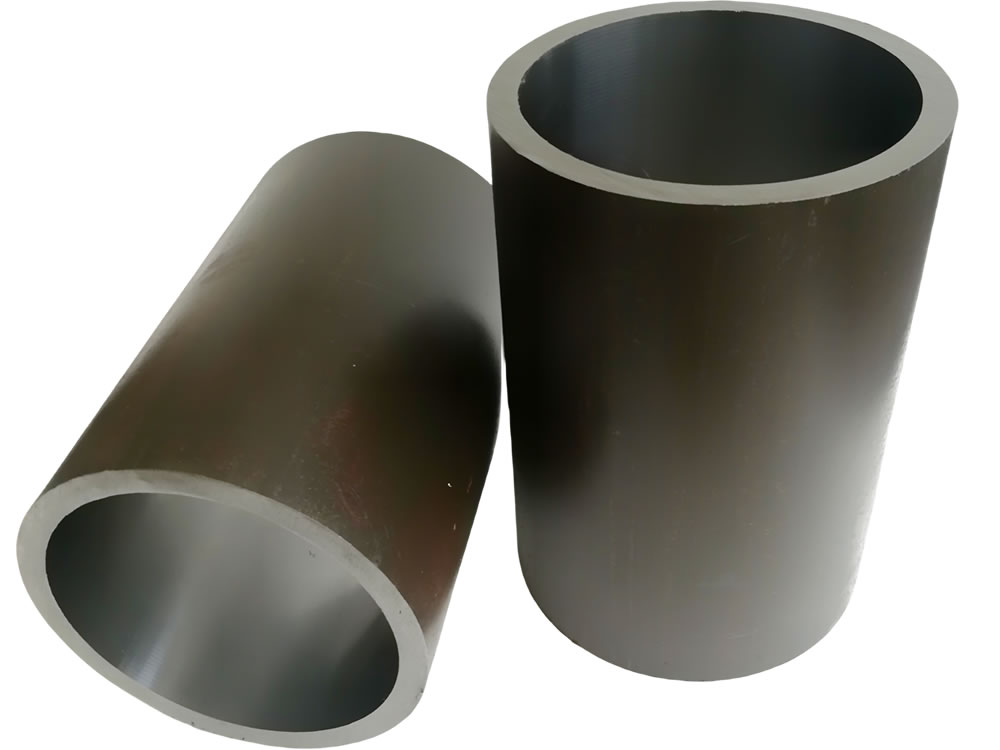

As the leading hydraulic cylinder honed tube suppliers, most of the factories can produce honed cylinder tubes in a wide range of metric sizes and imperial sizes. Here below is the typical size range of honed tubes.

Inside Diameter 32mm to 600mm; Imperial sizes equally.

Normally honed tubing is supplied in fixed length or random lengths, the max. Length of honed tube is 14 meters, sometimes even longer for special application purpose.

The specific size of a hone tube can vary depending on its application and the requirements of the user. Common sizes for hone tubes can range from small diameters like 1 inch (25.4 millimeters) to much larger diameters exceeding 10 inches (254 millimeters). The precise size you need would depend on the intended use, such as hydraulic cylinders or pneumatic systems, and the tolerances required for your application.

The tube size e quality of steel required for the project were not standard, so it had been necessary not only to manufacture the tube on customer’s specification, starting from a specific raw material tube but also to plan a peculiar manufacturing process.

For example, also both left ends had been treated in order to let the assembly of the piece. It has to be stressed the importance of honing the left ends and the roundesses where the O-Ring is allocated since they impact dramatically on the system performance.

Honed tubes are used in a variety of industrial applications, primarily in hydraulic and pneumatic systems. Here are some common uses of honed tubes:

Hydraulic Cylinders: Honed tubes are extensively used in hydraulic cylinders, which are essential components in machinery like construction equipment, agricultural machinery, and manufacturing machinery. The smooth inner surface of honed tubes reduces friction and wear, improving the efficiency and longevity of hydraulic systems.

Pneumatic Cylinders: Pneumatic cylinders, used in compressed air systems, also benefit from the precision and smoothness of honed tubes. They are employed in various industries for tasks such as material handling and automation.

Automotive Components: Honed tubes can be found in automotive shock absorbers, steering systems, and transmission systems. They provide the necessary strength, precision, and durability for these critical components.

Industrial Equipment: Honed tubes are used in various industrial machinery and equipment, such as printing presses, machine tools, and injection molding machines, where precise and smooth movement is essential.

Food and Pharmaceutical Industries: In environments where cleanliness and corrosion resistance are critical, such as food processing and pharmaceutical manufacturing, stainless steel honed tubes are employed to ensure the highest hygiene standards.

Oil and Gas: Honed tubes are utilized in hydraulic systems within the oil and gas industry, including applications like drilling equipment and hydraulic control systems on offshore platforms.

Aerospace: Precision-engineered honed tubes play a role in aerospace applications, including landing gear systems and actuation systems for aircraft.

Marine: Honed tubes are used in marine hydraulic systems due to their resistance to corrosion in saltwater environments.

Honed tubes serve the purpose of providing a smooth and precisely finished internal surface for hydraulic and pneumatic cylinders. These tubes are essential in cylinder manufacturing because they contribute to:

Improved Performance

The smooth internal surface reduces friction and wear, enhancing the overall performance and efficiency of hydraulic and pneumatic cylinders.

Seal Compatibility

The high-precision finish ensures proper sealing, preventing leaks in the cylinder system.

Strength and Durability

Honed tubes can be made from materials with high pressure resistance, ensuring the longevity and reliability of the cylinders.

Custom Sizing

Manufacturers can create honed tubes with specific dimensions to meet the requirements of various cylinder designs. In summary, honed tubes play a crucial role in optimizing the functionality, sealing, and durability of hydraulic and pneumatic cylinders.

Honed tubes are manufactured to meet specific technical specifications, including:

Honed tubes are an essential component in many industrial applications where precision and performance are critical. Their smooth inner surface and precise dimensions make them ideal for use in hydraulic and pneumatic cylinders, as well as other engineering applications where high-quality tube performance is required.

The honing process involves using abrasive polishing stones and abrasive paper to remove small amounts of material, to produce extremely precise ID dimensions and improved finishes. Honed tubing is ready to use for hydraulic cylinder applications without further ID processing.

Honed tube is well known as the best material to manufacture hydraulic cylinders. This is because honed tubes are the most critical materials for hydraulic cylinders. Honing is essentially a bore sizing and surface preparation process.

The tubes surface finishing is NBK, where the tubes are phosphate and normalized which provides corrosion resistance. It is oiled inside and outside. Normalize process creates tougher metal product. During normalizing, metals will be heated at a high temperature, and it allowed to naturally cool back down to room temperature by exposure after heating. Metals that have been through this process are more formable, harder and ductile.

The honing process is a form of grinding and a processing method in finishing. Not only with high productivity, but also with high machining accuracy, the function is to improve the surface finish and wear resistance of the honed tubes.

Step 1. Raw Material selection:

Select round bars of suitable size that meet the standards as raw material bars for processing;

Step 2. Billeting

Free forging and heat treatment process: the steel round bar is processed by billeting, free forging and heat treatment;

Step 3. Straightening

Forging hammer straightening on the treated raw material bar;

Step 4. Making mother tubes by Hot Rolling, Hot extrusion or Hot piercing.

Make the mother seamless pipes from the round steel bars, through the manufacturing process of either Hot Rolling, Hot extrusion or Hot piercing.

Step 5. Cold drawing

Cold draw the seamless mother pipe to make cold drawn seamless tubes (CDS tube), and to make it pre-honed tubes.

Step 6. Honing on the tube inner diameter

The ID (inner diameter) of the tube is honed with honing stone, so that the through inner diameter of the tube can meet the size and machining accuracy requirements of seamless honed tubes;

Step 7. Inspection and packing:

Inspect the finished honed tubes according to customers’ requirements and corresponding standards, to ensure they can meet the required size and machining accuracy requirements, mechanical properties, chemical compostions, etc.

Allowable working pressures are calculated using as per DIN 2413 at normal temperature. The yield and tensile stress values utilize to determine the maximum allowable running pressure and wall thickness required. The tubes and pipes are delivered the actual yield and tensile stress values are verified from the true copy material certificates. Pressure reduction factors at various temperatures show below:

| ° C | -40 | 120 | 150 | 175 | 200 | 250 |

|---|---|---|---|---|---|---|

° F |

-40 |

248 |

302 |

347 |

392 |

482 |

Rating Factor |

0.90 |

1.0 |

0.89 |

0.89 |

0.83 |

NA |

Hydraulic steel tube is designed to convey liquid fluids to among hydraulics components, fittings, valves, flanges, and other tools. It is made of material E355 (ST 52.4) or E235 (ST 37.4). These two grades have different chemical composition. This helps to control the working pressure.

| Chemical Composition (%) | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|

| E355 (ST52.4) | ⩽ 0.22 | ⩽ 0.55 | ⩽ 1.6 | ⩽ 0.045 | ⩽ 0.045 |

| E235 (ST37.4) | ⩽ 0.17 | ⩽ 0.35 | ⩽ 1.2 | ⩽ 0.045 | ⩽ 0.045 |

Hydraulic tube is made according to DIN 2391/C (DIN EN 10305-1) or DIN 2445/2 (DIN EN 10305-4) standards and it is available in millimeters, inches outer diameter, and inches nominal bore size.

The honed tubes suitable for various kinds of Precision Mechanical Tube, Honed Cylinder Tubing and Hydraulic Cylinder, Construct use Multi Joint Tube, Steel Axis Pipe, Injection Machine and Robotic Arm.

Seamless Honed Tubes (Steel) with a micro-finish and highly accurate in bore size within tolerance H7 or equivalent.

Grade: ST 52, ST52.3, CK45, E355, 16Mn, STKM13C, SAE1020, SAE1026, SAE1045

Honed Tubes are ready to use for hydraulic cylinder applications without further ID processing.

Different sizes of ready to use honed tube are available.

| ID(mm) | TOLERANCE(mm) | |||

|---|---|---|---|---|

| H7 | H8 | H9 | H10 | |

| ≦30 | +0.021/0 | +0.033/0 | +0.052/0 | +0.084/0 |

| 30 – ≦50 | +0.025/0 | +0.039/0 | +0.062/0 | +0.100/0 |

| 50 – ≦80 | +0.030/0 | +0.046/0 | +0.074/0 | +0.120/0 |

| 80 – ≦120 | +0.035/0 | +0.054/0 | +0.087/0 | +0.140/0 |

| 120 – ≦180 | +0.040/0 | +0.063/0 | +0.100/0 | +0.160/0 |

| 180 – ≦250 | +0.046/0 | +0.072/0 | +0.115/0 | +0.185/0 |

| 250 – ≦315 | +0.052/0 | +0.081/0 | +0.130/0 | +0.210/0 |

| 315 – ≦700 | +0.057/0 | +0.089/0 | +0.140/0 | +0.230/0 |

This will provide long piston seal life and prevent failure of the cylinder. The tube material is selected on the basis of application & working pressure.

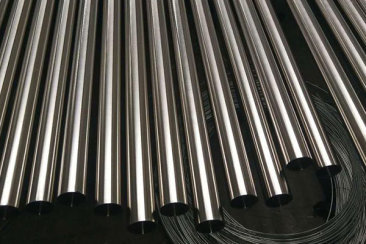

The seamless tube for hydraulic cylinders, obtained from high quality cold drawn tubes, available in a wide dimensional range.

Carbon steel Hydraulic Cylinder Tubing is available with grades as below:

Stainless steel Honed tube can be supplied in grades as below:

Other steel grades of hone tube /honed pipe is available on customer’s request.

Roller burnished tube is a type of metal tube that has undergone a specialized finishing process to achieve a smooth and polished surface texture.

This process involves the use of precision rollers to apply pressure and polish the outer surface of the tube, resulting in enhanced strength, improved corrosion resistance, and reduced friction.

Related keywords related to roller burnished tube on Google may include:

Precision rolled tube is a type of tubing that is produced using a precision rolling process.

Precision rolled tubes are often used in applications that require high-quality and precise dimensional tolerances. They are commonly used in industries such as automotive, aerospace, and medical, where accuracy and consistency are crucial. These tubes can be made from various materials including stainless steel, aluminum, copper, and brass. They can also be produced with specific mechanical properties, such as high strength or corrosion resistance, to suit the specific requirements of the application.

Hydraulic cylinder tubes are precision-made hollow cylinders, typically constructed from steel or other high-strength materials, designed for use in hydraulic systems.

Hydraulic cylinder tubes play a crucial role in hydraulic systems and find applications in various industries:

These tubes serve as the main component of hydraulic cylinders, providing the housing for the piston and rod assembly. They allow hydraulic fluid to act upon the piston, generating linear motion.

Hydraulic cylinders are used in construction machinery like excavators, backhoes, and bulldozers for tasks such as lifting, digging, and pushing.

Hydraulic cylinder tubes are integral in manufacturing equipment, including presses, injection molding machines, and metal forming machines, where precise control of force and motion is essential.

They are employed in agricultural equipment such as tractors, combines, and plows for functions like raising and lowering attachments and steering.

Hydraulic cylinders play a vital role in material handling equipment like forklifts and conveyor systems for lifting and transporting goods.

In aircraft, hydraulic cylinders are used in landing gear, control surfaces, and cargo loading systems.

Hydraulic systems in ships and boats utilize hydraulic cylinders for steering, stabilizing, and other operations.

The mining industry relies on hydraulic cylinders for equipment like drills, loaders, and crushers.

Hydraulic cylinders are used in various automotive applications, including convertible top mechanisms, power steering systems, and brake systems.

In the context of machining and manufacturing, a "boring tube" refers to a tool or device used for the process of boring.

Boring is a machining operation used to enlarge or refine an existing hole or cavity in a workpiece. The boring tube is inserted into an existing hole to accurately shape and size it to the desired specifications. It is a cylindrical tool that rotates and cuts to achieve the desired precision in machining internal diameters or holes. Boring tubes are commonly used in various manufacturing processes to create accurate and precise bores in mechanical parts and components.

Keywords related to Boring tube on Google may include:

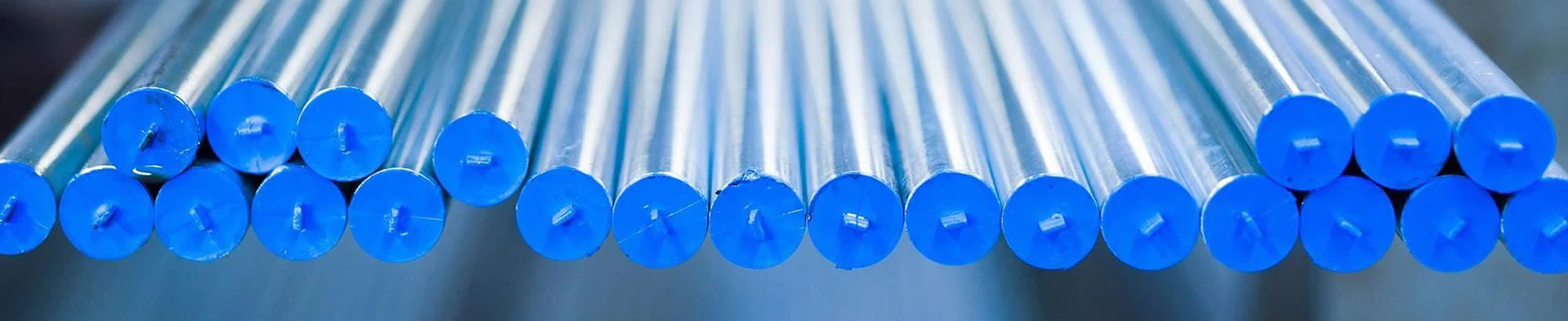

A piston rod is a component in a piston-cylinder arrangement used in various mechanical systems, such as internal combustion engines, hydraulic cylinders, and pneumatic cylinders.

It is a cylindrical rod that extends from the piston and connects it to the crosshead or the connecting rod in an engine or the piston in a hydraulic or pneumatic cylinder.

In an internal combustion engine, the piston rod connects the piston to the crankshaft, converting the reciprocating motion of the piston into rotational motion of the crankshaft, which drives the engine's operation.

In a hydraulic cylinder, the piston rod extends and retracts to move the piston inside the cylinder, converting hydraulic pressure into linear mechanical force.

In a pneumatic cylinder, the piston rod is similarly used to extend and retract the piston, converting compressed air pressure into linear mechanical motion.

Piston rods are usually made of high-strength materials like steel to withstand the forces and stress encountered during their operation. They are crucial components in many mechanical systems and play a vital role in converting energy and transmitting motion in various applications.

A galvanized hydraulic tube refers to a hydraulic tube that has undergone a galvanizing process.

Din2391 Galvanized Hydraculic Precision Steel Tubes Synopsis of Process Routing:DIN highly accurate, cold rolled and bright seamless steel tube is used as the tube to be galvanized. The outer wall of tube is electroplating.

When producing galvanized steel tubes, we use no-oxygen furnace to annealed the tubes which ensuire the smoothness of the inner and outside surface.Both the inner and outer surfaces of the high precision steel tubes can be galvanized or Zn only coated to the outside diameter,giving the tube a high homogeneity and an excellent rust resistant performance.

Our Hydraulic manufactures honed steel tubes and skived roller burnished tubes designed for use in hydraulic and pneumatic cylinders. Our products are known for their high quality and competitive prices. We offer both imperial and metric sizes to suit your specific needs.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.