White 92% high ceramic alumina lined wear resistant bend pipe is made through self-propagating high-temperature synthesis (SHS) technique.

Download PDFWear resistant alumina ceramic rings are ceramic components specifically designed to withstand wear and abrasion in various industrial applications. These rings are made from alumina ceramic, which is known for its high hardness and wear resistance.

Alumina ceramic rings exhibit exceptional hardness, making them resistant to wear and abrasion.

These rings are designed to withstand the harsh conditions of abrasive environments, maintaining their integrity and shape.

Alumina ceramic is chemically inert, providing resistance to corrosive substances and chemicals.

Alumina ceramic rings have excellent thermal stability, allowing them to withstand high temperatures without deformation or degradation.

The low friction coefficient of alumina ceramic reduces friction and wear in applications where sliding or rotating movements are involved.

Alumina ceramic rings possess excellent electrical insulation properties, making them suitable for electrical applications.

| 性能 Properties |

单位 Units |

Cordierite Ceramic 堇青石 |

Mullite Ceramic 莫来石 |

95%Alumina Ceramic 氧化铝 |

99%Alumina Ceramic 氧化铝 |

99.5%Alumina Ceramic 氧化铝 |

99.7%Alumina Ceramic 氧化铝 |

Silicon Nitride 氮化硅 |

Zirconia Ceramic 氧化锆 |

|---|---|---|---|---|---|---|---|---|---|

| Colour 颜色 |

- | Yellow | White | White | Light yellow | Light yellow | Light yellow | Black | White |

| Density 密度 |

g/cm³ | 1.9 | 2.6 | 2.6 | 3.6 | 3.8 | 3.9 | 3.2 | 6 |

| Flexural Strength 抗弯强度 |

MPa | 30 | 120 | 200 | 250 | 350 | 375 | 800 | 1100 |

| Compressive Strength 抗压强度 |

MPa | 350 | 500 | 2500 | 2800 | 2800 | 2554 | 2600 | 3000 |

| Modulus of Elasticity(20°C) 弹性模量 |

Gpa | 40 | 100 | 300 | 350 | 360 | 357 | 290 | 320 |

| Max Use Temperature 最高使用温度 |

°C | 1200 | 1300 | 1400 | 1500 | 1500 | 1760 | 1300 | 1050 |

| Thermal Conductivity 热导系数 |

W/m.K | 1.3 - 1.8 | 2 - 6 | 20 | 30 | 30 | 33 - 38 | 25 | 3 |

| Thermal Expansion Coefficient 热膨胀系数 |

10⁻⁶/°C | 2.5 - 3 | 2.5 - 3 | 5 | 8 | 8.2 | 8.2 | 3 | 10 |

| Thermal Shock Resistance 抗热震性 |

ΔT°C | 300 | 150 | 140 | 150 | 200 | 223 | 600 | 250 |

| Dielectric Strength 击穿强度 |

KV/mm | - | - | 15 | 18 | 18 | 23.4 | 25 | 15 |

| Dielectric Constant 介电常数 |

Er | 8 | 8 | 9 | 9.2 | 9.2 | 9.84 | 9 | 26 |

Alumina ceramic rings are used in pump systems as wear-resistant components, such as plungers and sealing rings.

These rings are utilized in mechanical seals to provide wear resistance and sealing capabilities in rotating equipment.

Wear resistant alumina ceramic rings can be found in valve assemblies, helping to reduce wear and extend the lifespan of the valves.

Alumina ceramic rings are used in bearing systems to reduce friction and wear in high-speed or high-load applications.

They can be incorporated into cutting tools to enhance their wear resistance and extend their tool life.

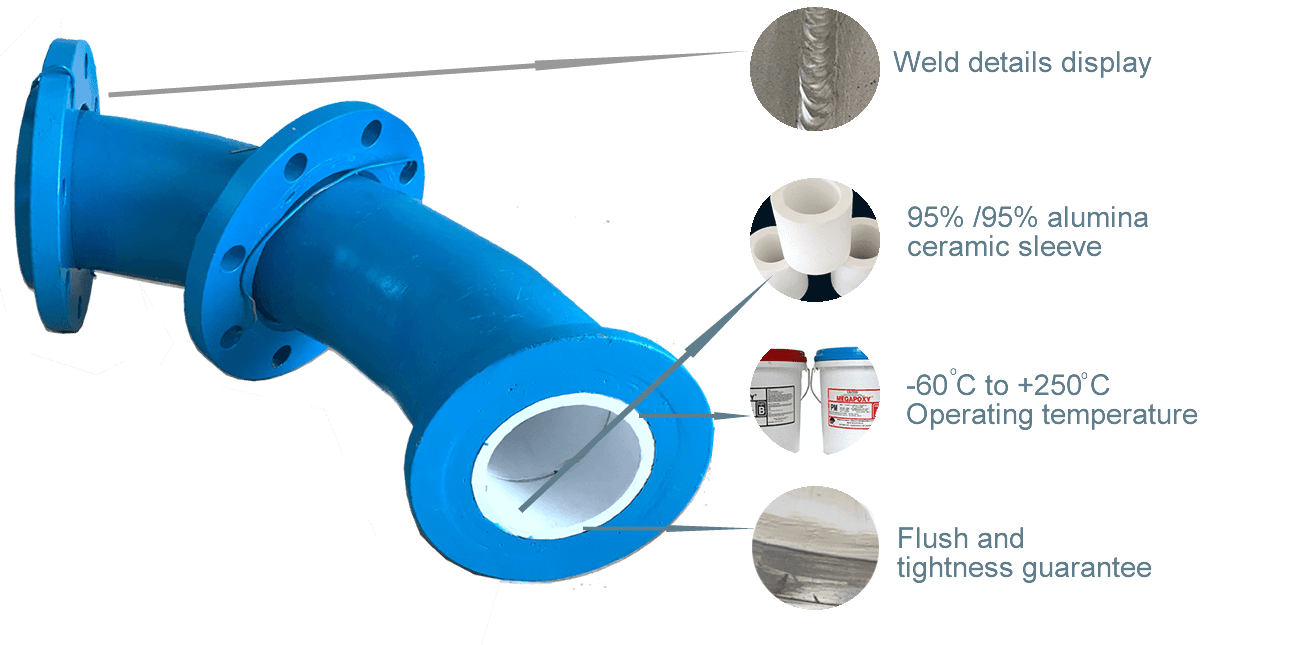

For different production environments, our company has developed a wear-resistant pipe for a variety of media, based on the temperature, wear and corrosion requirements of the field media, and for the initial application of the scene, our company to provide wear-resistant ceramic ring for the Lined composite straight pipe design to meet the on-site wear resistance, heat resistance and corrosion resistance requirements, in view of this program for the new design (formerly ceramic chip technology, there are many gaps, easy to wear).

After the ceramic ring in the pipe is installed and the thread is processed, the dirt outside the pipe is cleaned, and the outer surface of the pipe is treated with three layers of anticorrosive paint to meet the export requirements.

| Item | Data | Characteristics of binder |

|---|---|---|

| Density (g/cm3) | 1.32 | We use the Australian Megapoxy high strength structural adhesive, this structural glue is modified epoxy resin polymer, anti-aging ability, and wear-resistant ceramic bonding to form a strong and cushion of the anti-wear layer, cured water, anti-corrosion performance is excellent, toughness, displacement-resistant effect is remarkable.

|

| Compressive strength (MPa) | 40 | |

| Shear Strength MPa | 26 | |

| Impact toughness Kj/m2 | 10 | |

| Hardness HB | 9.5 | |

| Elastic Modulus GPa | 2.2 | |

| Expansion coefficient 10-6/℃ | 20.1 | |

| Softening temperature℃ | 263 | |

| Coking temperature℃ | 335 | |

| Acid resistance(24H) | Stability | Test solution : 15%H2SO4 |

| Alkali resistance(24H) | Stability | Test solution: NaOH |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.